Ziegler Group: Naturheld Insulating Materials for Sustainable Building

The Ziegler Group has its headquarters in Betzenmühle in the Upper Franconian town of Plößberg. As the largest sawmill in Europe, it has been primarily active in this segment for over 75 years. The annual cut amounts to over 2 million cubic meters of round timber.

Subsidiary Naturheld: high-quality insulation materials made from wood chips and waste wood

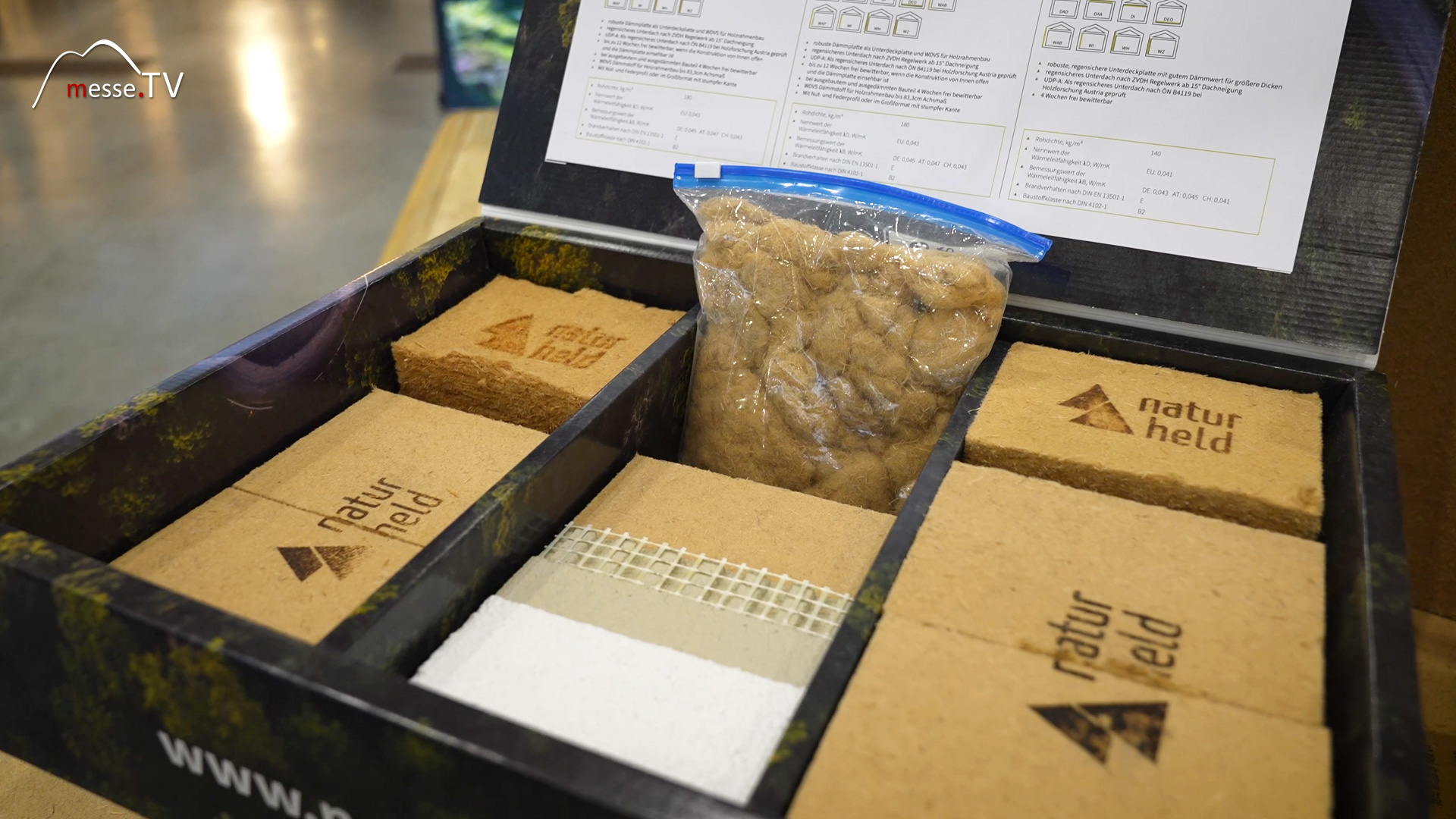

The Ziegler Group will be presenting its subsidiary Naturheld at the Dach+Holz 2024 trade fair. Here, wood chips and waste wood are processed into high-quality insulation materials in flex and compression-resistant wood fiber at the Hütten plant near Grafenwoehr. The plant was newly built in 2021 and is already one of the largest producers of wood fiber insulation materials in Europe with the three production lines "pressure-resistant line", "flex line" and a blow-in insulation line. The sustainable products are made from wood fibers with small amounts of additives.

Naturheld insulation products and their areas of application

The pressure-resistant Naturheld board is used in the façade and roof. The flexible insulation mat is traditionally used in the intermediate rafters or in the compartment insulation. The blow-in insulation is also used in the cavity. Each of these lines conserves resources, as well over 90% wood fiber is used for production. The waste wood is produced at the Betzenmühle headquarters and is processed in huts in a closed loop. A more than sensible addition to the Ziegler Group's product portfolio.

New construction and renovation - Insulation with ecologically valuable materials

Traditional carpentry companies working in new construction are ideal customers. But these products are also ideal for renovations, façade insulation, etc. Naturheld products fit in perfectly with the new Insulation Ordinance - both in an ecological sense and with regard to the law on the circular economy. The material can be used in many ways and fits in with our environmentally conscious times.