Siemens Motion Control - Efficient control technology for robots and drives

Siemens is setting new standards in automation with the latest generation of its motion control technology. The SIMATIC Robot Library simplifies the integration of different robot manufacturers and ensures a standardized control concept. With the latest generation of controllers and the optimized TIA Portal V20, motion control integration is more efficient than ever before, ensuring greater flexibility and performance, especially in industrial production.

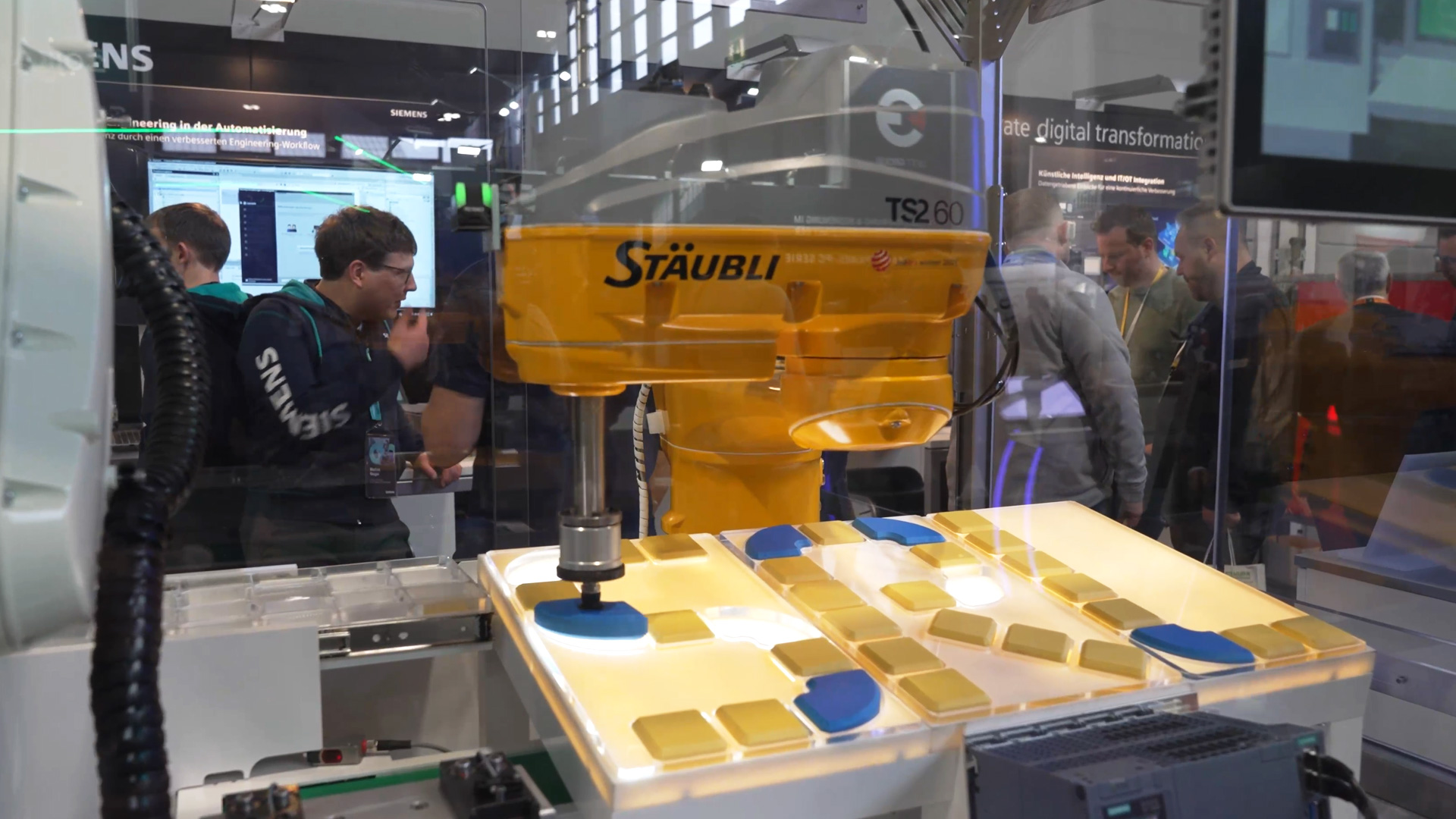

SIMATIC Robot Library - Standardized robot control for more flexibility

A central highlight is the SIMATIC Robot Library, which provides a standardized interface for different robot manufacturers. Together with leading robotics companies, Siemens has developed the Standard Robot Command Interface (SRCI) to enable cross-manufacturer control. This means that robots from different manufacturers can be easily integrated into existing automation processes without having to program separate control logic for each brand. This technology offers companies better scalability and greater investment security, as they are not dependent on a single robot manufacturer. At the same time, the interface enables faster and simpler commissioning, which reduces automation costs and minimizes maintenance work.

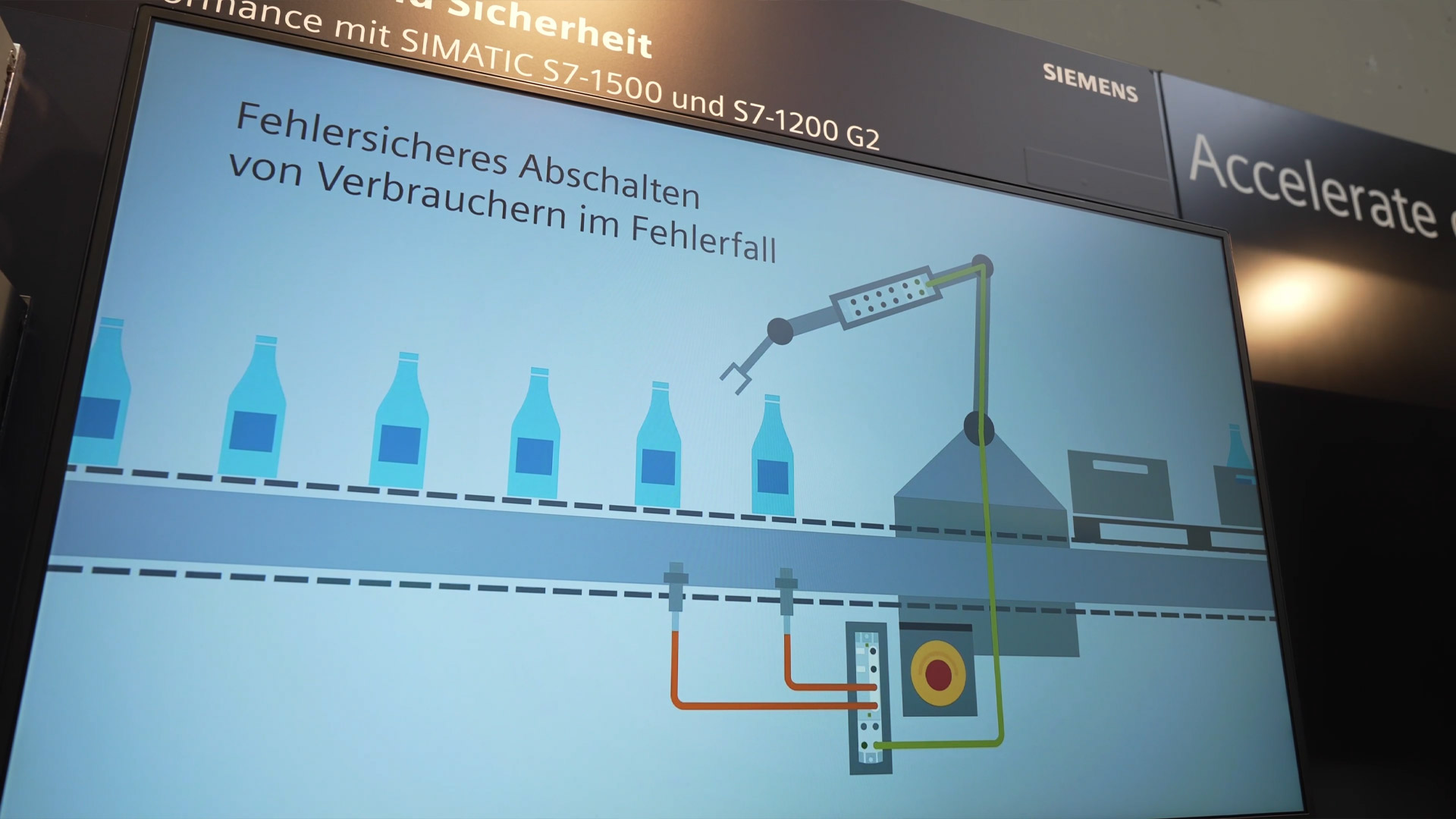

New controller generation: More power for motion control and kinematics

Siemens is presenting the new S7-1200 Generation 2 at the trade fair, which has been optimized in particular for demanding motion control applications. Compared to the first generation, this controller allows more complex, coordinated axis movements, which are particularly suitable for cam controls or Cartesian gantries with orientation. In addition to the S7-1200, Siemens is also presenting the more powerful S7-1500 controllers, which are suitable for larger automation projects with many drives. The new 1518TF CPU offers two and a half times more performance than its predecessor model and enables even more precise control of drives and motion sequences. A particular advantage of the new generation of controllers is their easy integration into existing production processes. Siemens has opted for a standardized engineering platform that simplifies the programming and networking of various components.

TIA Portal V20 - Standardized engineering for greater efficiency

The new TIA Portal V20 plays a central role in Siemens' control technology. It offers an optimized user interface with which controllers, drives and motion control applications can be programmed and networked in a single system. Particularly noteworthy is the automatic networking between the controller and inverter, which allows data and diagnostics to be exchanged seamlessly. This improves alarm handling, as error messages relating to motor overheating, for example, are sent directly to the controller and visualized. Another highlight is the integration of artificial intelligence (AI) into the programming. With the Industrial Copilot, Siemens supports automation engineers with recurring tasks such as searching for and replacing program code or optimizing network connections. This intelligent assistance function reduces the time required for commissioning and facilitates the implementation of new automation solutions.

Future-proof automation with second supplier options

Another important issue for companies is flexibility in the selection of components. Here, Siemens relies on an open structure that allows different automation solutions to be combined with each other. The TIA Portal and the Siemens libraries offer a broad integration of third-party components so that companies are not dependent on a single supplier. This strategy allows for greater diversity in automation technology, improves adaptability to specific production requirements and reduces the risk of dependencies in the event of supply chain bottlenecks. With the combination of SIMATIC Robot Library, powerful controllers and an optimized engineering process in TIA Portal, Siemens offers a scalable, efficient and flexible automation solution that is suitable for both small and large industrial applications.

What does Siemens do?

Siemens AG is a leading global technology company with a focus on industry, infrastructure, mobility and healthcare. The company develops solutions that aim to change lives for the better. With a broad portfolio, Siemens offers products and services ranging from industrial automation and intelligent infrastructure solutions to state-of-the-art medical technology. Through continuous innovation, Siemens contributes to improving the quality of life and driving sustainable developments.