Lenze Motor Drive: Efficiency, economy and sustainability combined

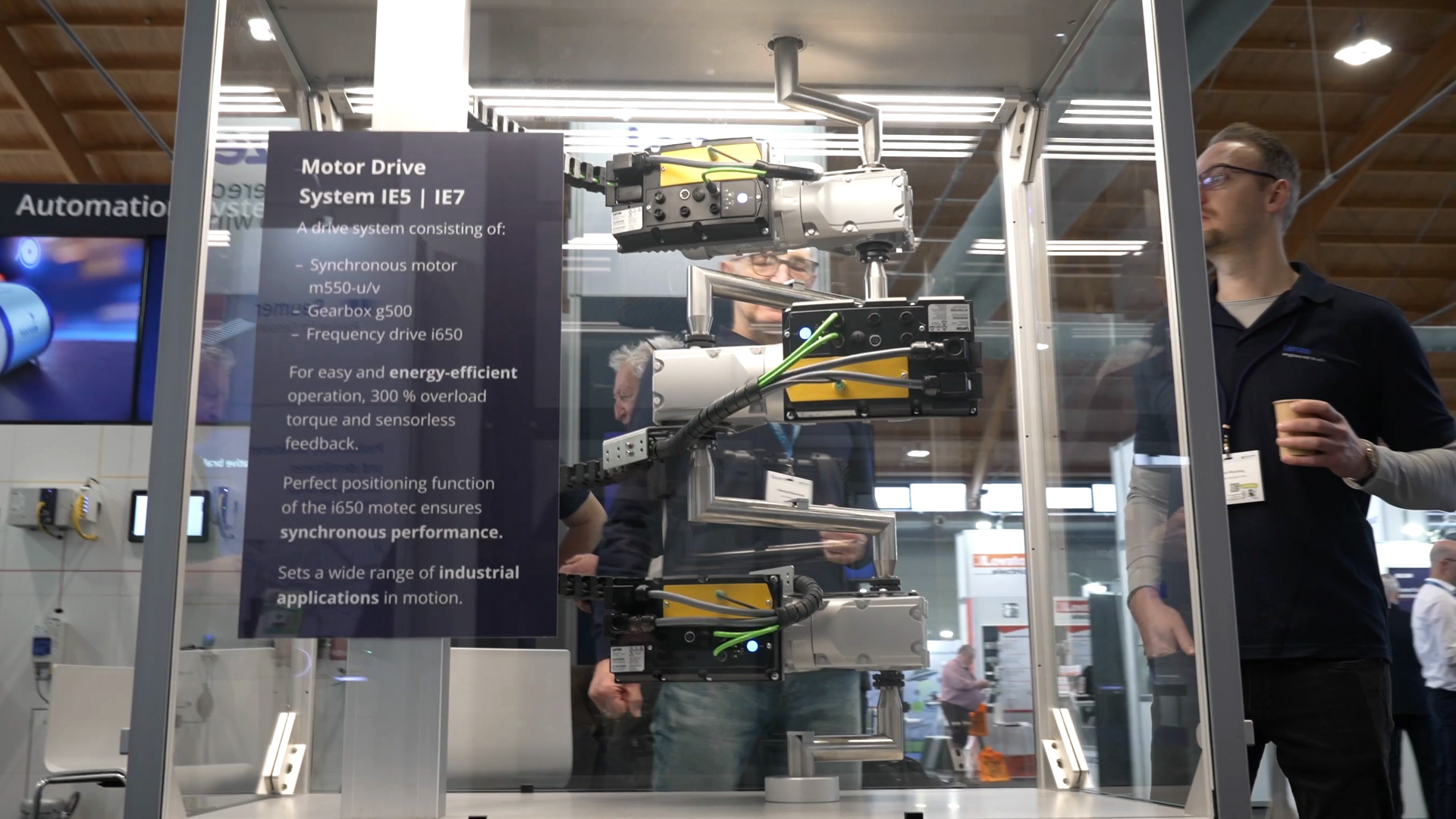

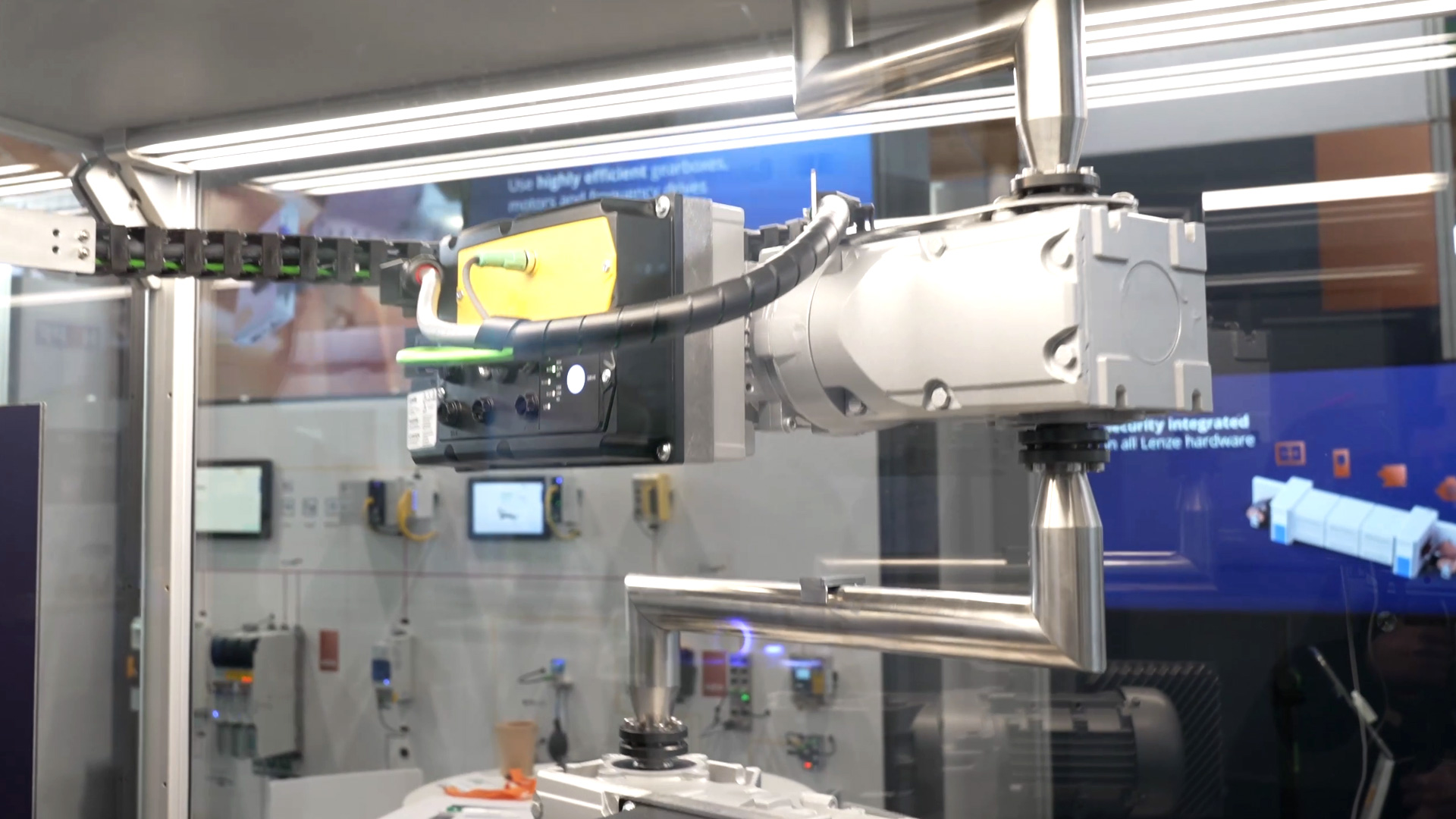

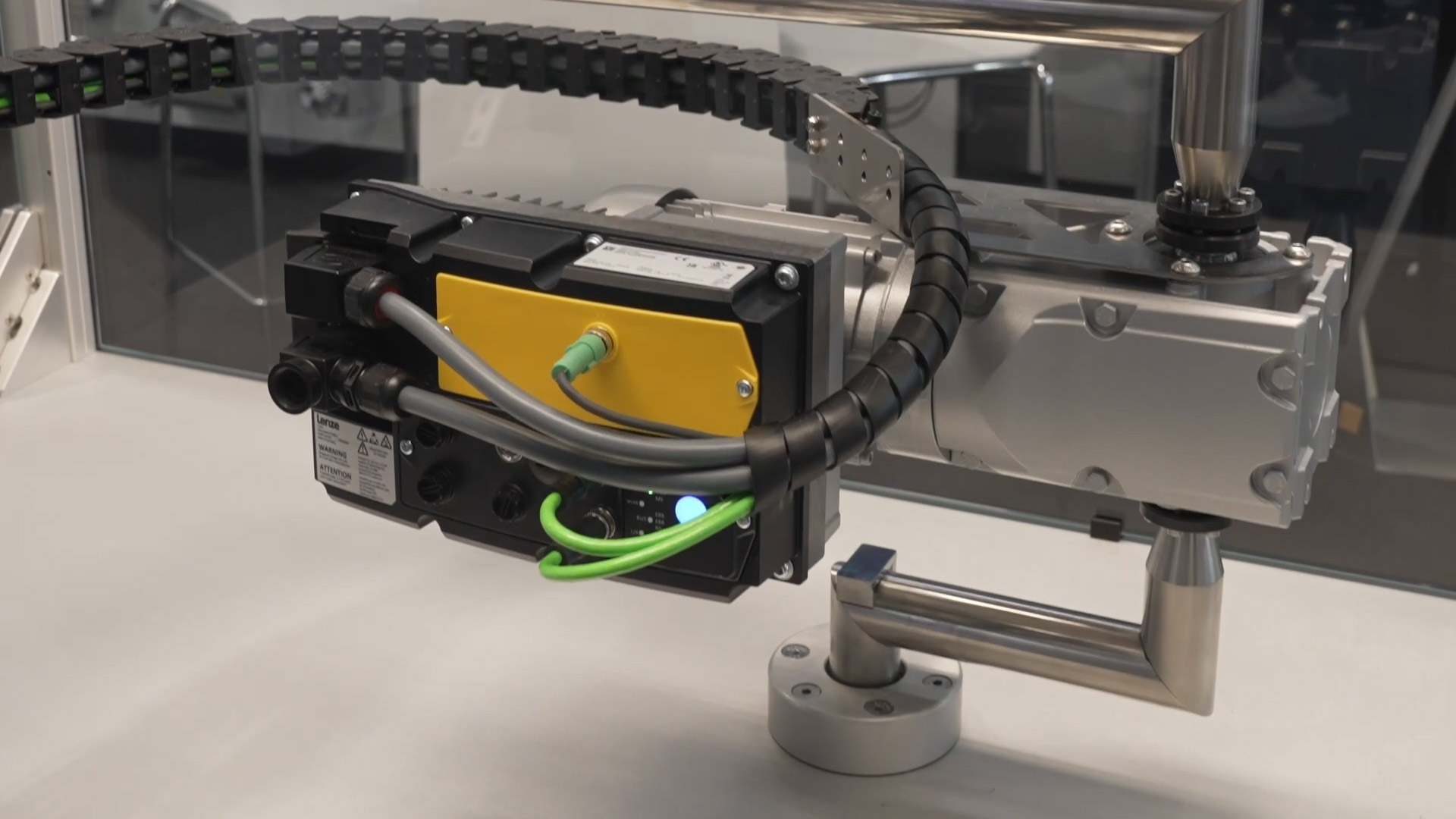

With the new Motor Drive System IE5/IE7, Lenze presents a ground-breaking drive solution that combines sustainability, economy and performance in one compact unit. The combination of highly efficient synchronous motor and intelligent frequency inverter enables encoderless positioning and ensures a significant reduction in energy consumption. The further development of drive technology has made it possible to combine the simplicity of asynchronous technology with the advantages of synchronous technology. The system therefore offers a powerful and cost-efficient alternative to conventional servo and asynchronous drives.

Sensorless positioning for maximum efficiency

Previous asynchronous drive systems have reached their limits, especially when it comes to energy efficiency and performance. With the Motor Drive System IE5/IE7, Lenze has created a solution that enables greater efficiency while reducing costs at the same time. Thanks to encoderless positioning, there is no need for additional sensors and cabling, which minimizes installation work and reduces operating costs. The efficiency of IE5 and IE7 enables considerable energy savings, especially in applications where high torques are required. The system saves resources and offers optimum controllability thanks to its innovative control system, even under demanding conditions.

Flexible use in various industries

The Motor Drive System is particularly suitable for applications in mechanical engineering, the textile industry, packaging technology and intralogistics. Wherever powerful but economical solutions are required, it offers an attractive alternative to classic servo drives and inverter systems. A major advantage is the high overload capacity of up to 300 %, which means that even high starting torques and load changes can be handled without any problems. This is particularly important for conveyor systems, winding processes or handling applications. In addition, the high dynamics allow precise control, which extends the range of possible applications. System integration is simple and flexible, as the Motor Drive System can be seamlessly integrated into existing systems. The modular design enables adaptation to different requirements and offers machine builders maximum design freedom.

Cost savings through intelligent system integration

A key argument in favor of the IE5/IE7 motor drive system by Lenze is the significant cost reduction compared to conventional systems. The combination of motor, inverter and controller in one unit enables savings of up to 40 % compared to conventional servo drives. These savings result from the elimination of external encoders, reduced cabling costs and an optimized drive architecture. By using them in medium-complex applications, mechanical engineering can be streamlined without having to compromise on performance or flexibility. With this innovation, Lenze proves that high efficiency, cost-effectiveness and simple integration can go hand in hand. The development of this system marks a decisive step towards sustainable and at the same time economical automation solutions.

What does Lenze do?

Lenze SE is a globally active company in the field of drive and automation technology with headquarters in Aerzen, Germany. Since its foundation in 1947, Lenze has developed from a trading company into a system provider offering high-quality mechatronic products, high-performance hardware and software solutions and digital services. With a global presence in over 45 countries, Lenze supports customers in efficiently automating and digitizing machines and systems.