XITO offers a manufacturer-independent platform for industrial automation that is specially designed to make getting started with robotics as easy as possible. Instead of complex individual developments, XITO relies on a modular approach that allows companies to configure their automation solutions themselves and put them directly into operation - without in-depth programming knowledge. Thanks to the three central steps "plan, buy, start", companies can automate their production processes quickly and efficiently without having to rely on complex and costly special machine construction. For small and medium-sized companies in particular, XITO offers an intuitive solution for using robotics flexibly and cost-effectively.

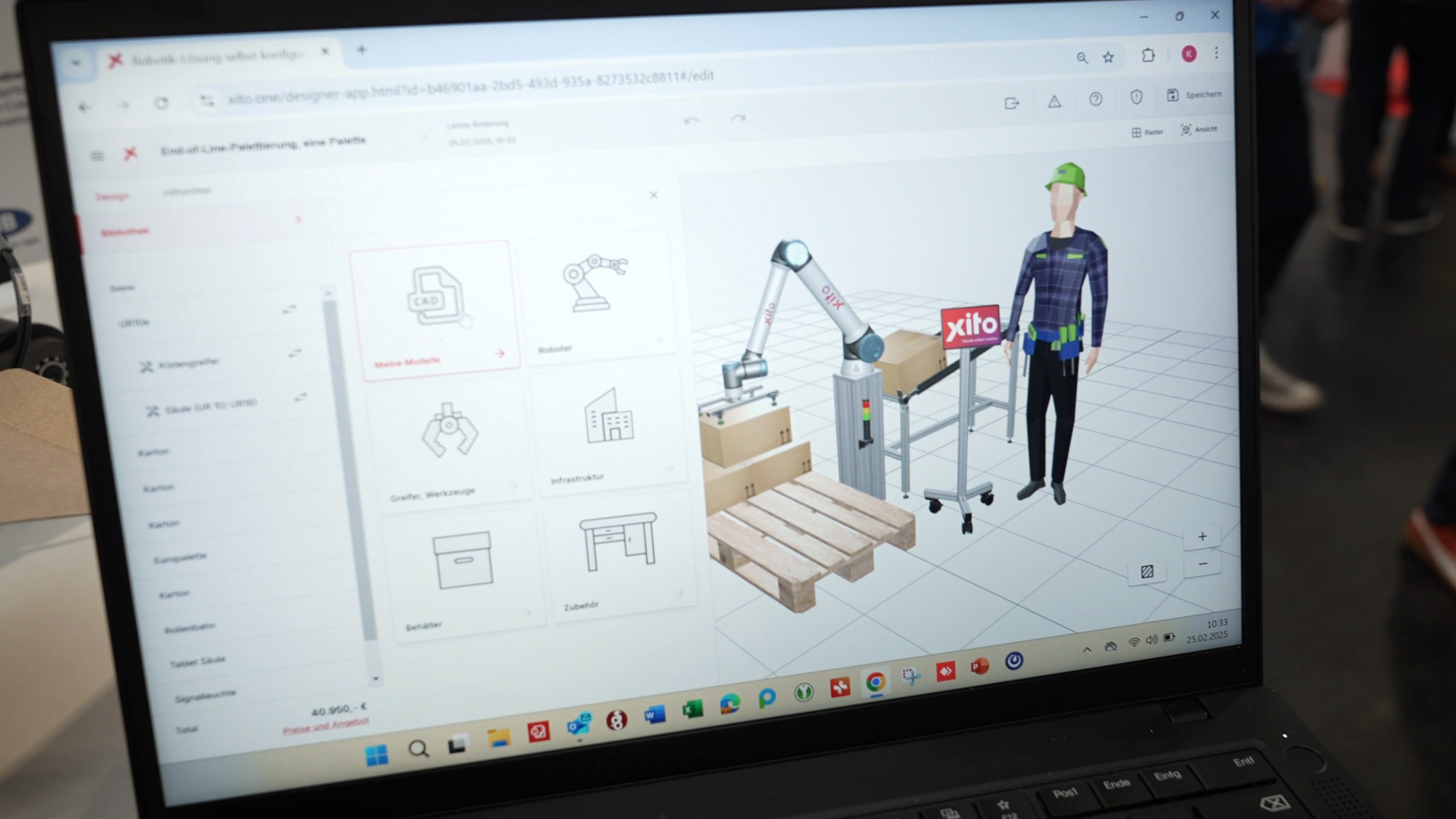

A central component of the platform is the XITO Designer, a 3D-supported planning tool that enables complete automation solutions to be put together individually. Users can select various components such as robots, grippers, conveyor belts or sensors and integrate them directly into a simulated production environment. A major advantage of the XITO Designer is its price transparency: the estimated costs for the entire solution are calculated in real time during configuration. This allows companies to directly assess whether automation makes economic sense and which adjustments may be necessary to achieve an optimum balance between costs and benefits. The planning tool has been specially developed for users without in-depth design experience. Instead of resorting to complicated CAD software, users can simply drag and drop various automation components together and test the simulation directly in a visual environment.

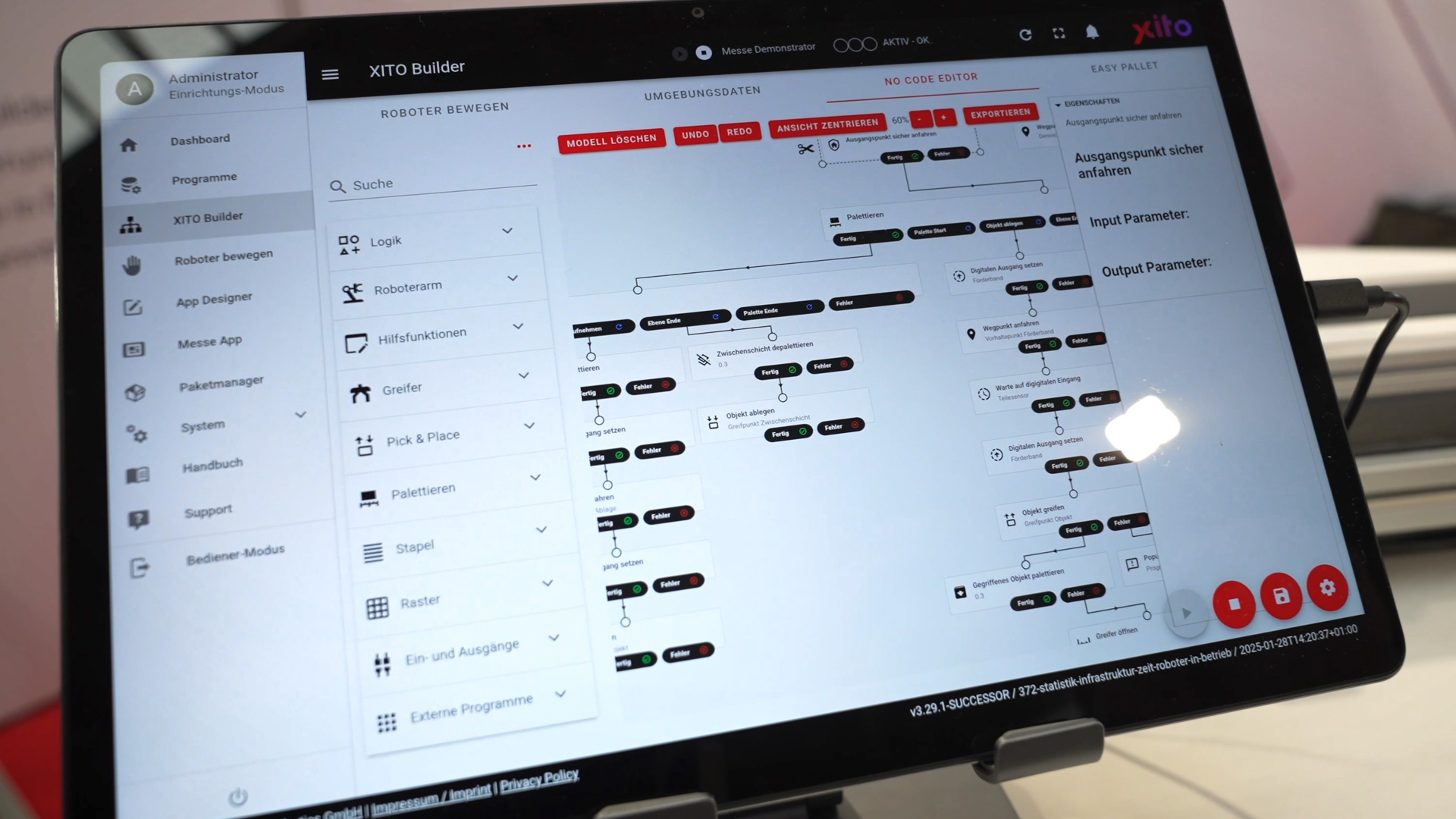

Planning is followed by implementation - and this is where XITO Builder sets new standards in the simple control and configuration of robots. With a no-code interface, robotic processes can be defined by simply clicking together building blocks without having to write a single line of code. This visual programming language enables even beginners to program complex processes such as gripping, positioning, depositing or palletizing intuitively. Predefined logic blocks ensure that every movement runs efficiently and error-free without the user having to delve deep into programming logic. The XITO Builder is a revolutionary solution, especially for small companies or manufacturing companies that are dealing with automation for the first time, as it removes high barriers to entry and makes it possible to get started with automation after just a short time.

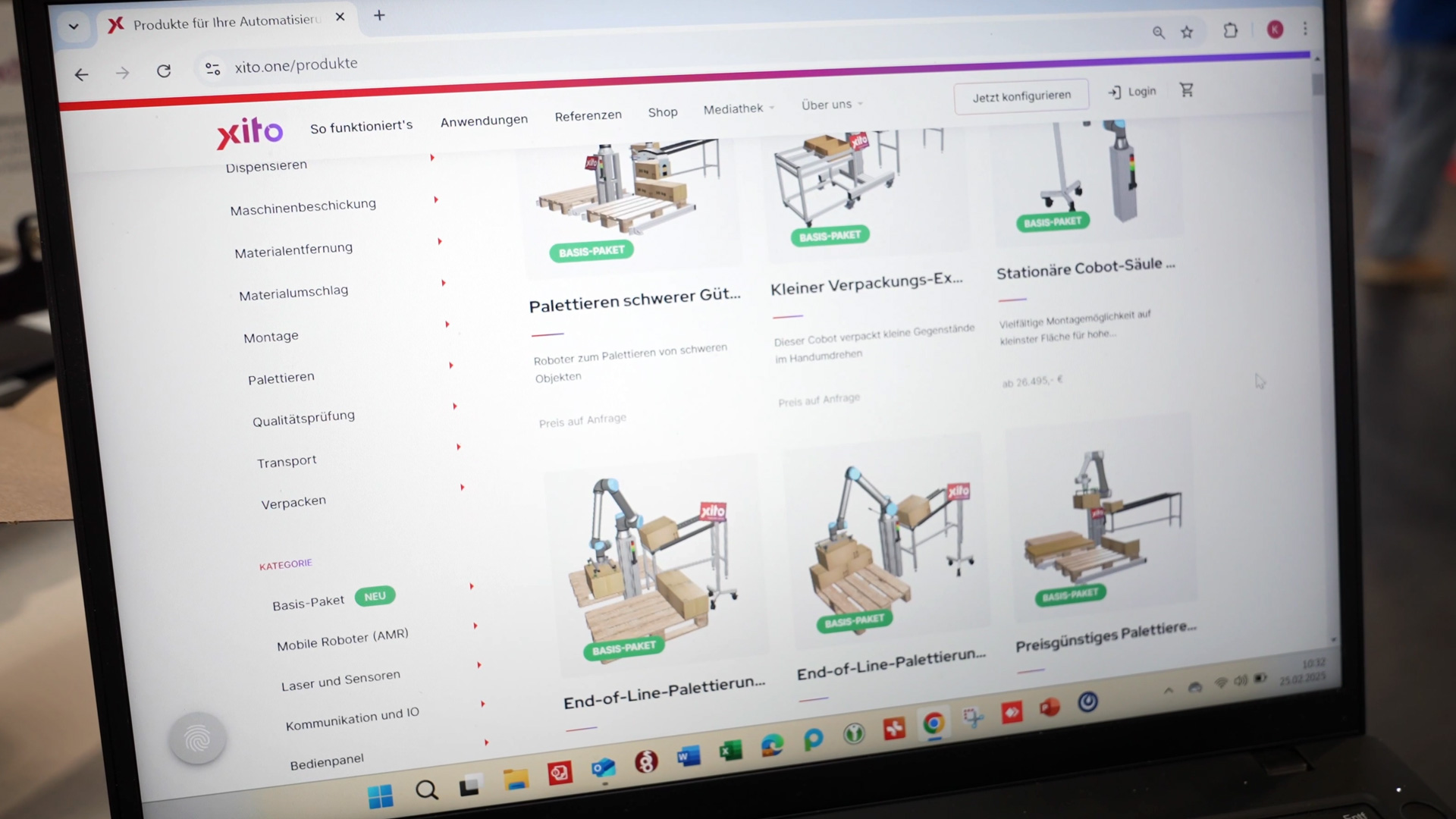

A particular advantage of the XITO platform is the flexibility in the choice of hardware. While many automation solutions are tied to a specific robot manufacturer, XITO offers manufacturer-independent compatibility. Companies can therefore choose from a wide range of robot models and accessories to find the perfect combination for their specific production environment. Various basic packages for different automation tasks are available in the XITO online store - for example for palletizing boxes, handling injection-moulded parts or simple pick-and-place applications. Companies can replace or adapt individual components at any time to further optimize their automation solution. Particularly practical: if one robot model is replaced by another, the entire price of the solution is automatically adjusted so that there are no hidden costs.

In addition to simple planning and configuration, XITO offers rapid implementation and integration into existing production processes. Most projects can be implemented in less than 100 days, as the platform is based on standardized modules that are ready for immediate use. Thanks to the close integration of hardware, software and CE certification, companies do not need to involve third-party providers or external integrators, but instead receive a complete, turnkey solution from a single source. A further advantage is the detailed documentation and training: XITO provides comprehensive step-by-step instructions, video tutorials and support materials to ensure that employees can quickly learn how to use the new automation solution.

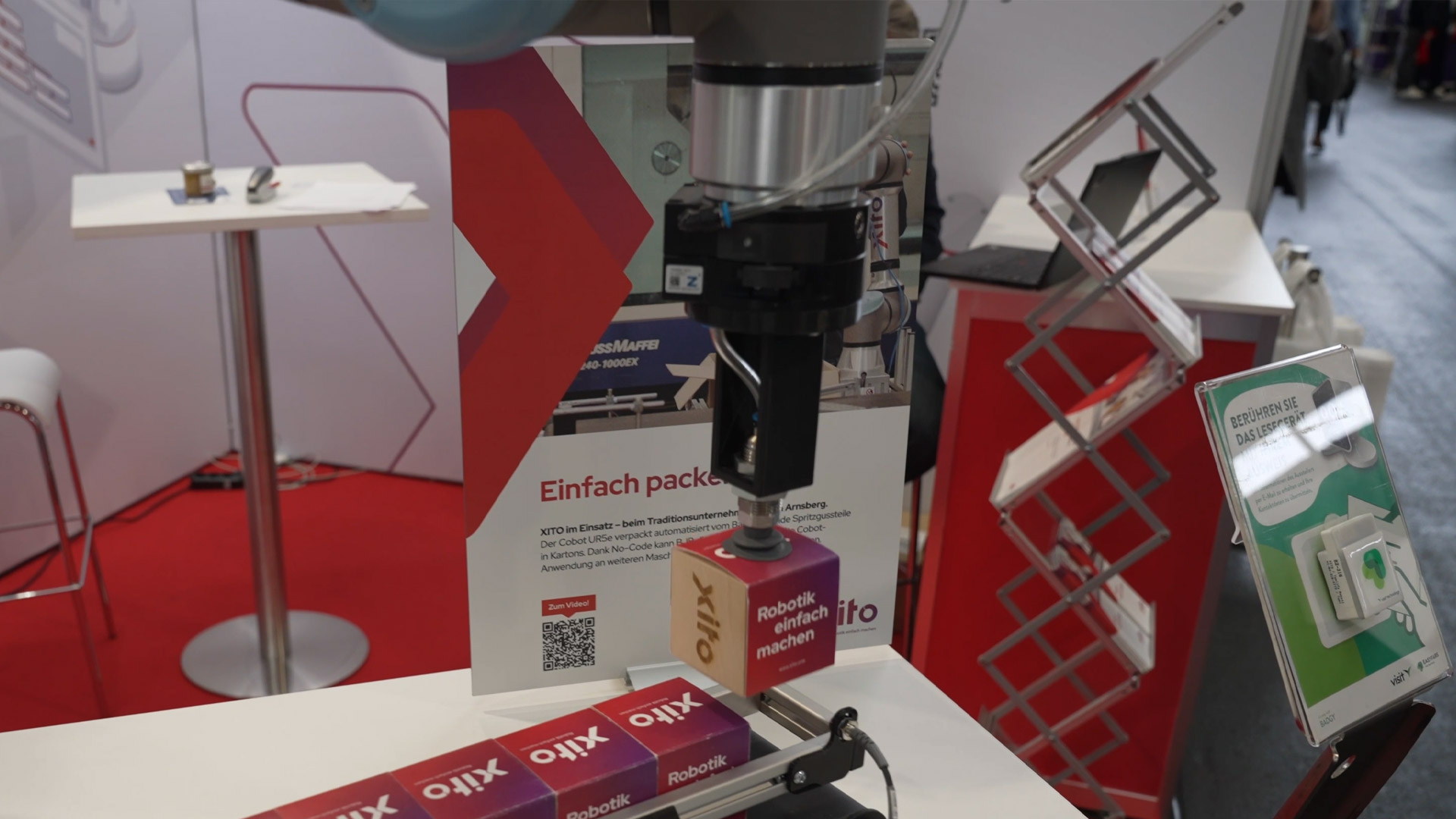

A successfully implemented project shows how XITO supports companies in making their production more efficient. A partner company has used the platform to develop an automated solution for packaging injection-molded parts. The finished plastic parts are automatically removed from the conveyor belt after production, packed in a box with intermediate layers and prepared for onward transportation. The entire solution was configured using XITO Designer, programmed in XITO Builder and successfully put into operation within a few weeks. Thanks to the manufacturer-independent component selection, the company was able to choose the optimum combination of robot, conveyor belt and vacuum gripper system to perfectly adapt the automation to its own production conditions.

While traditional online stores for automation technology usually only offer individual components without integration and special machine manufacturers develop high-priced, customized solutions, XITO closes precisely this gap. The platform enables companies to design their automation solution themselves, while keeping an eye on costs and implementation and still receiving a tailor-made solution for their specific production requirements. With this approach, robotics finally becomes accessible to every company - regardless of size, budget and technical experience.

XITO is a solution platform developed by Toolify Robotics GmbH that enables small and medium-sized companies to implement robots independently. The platform guides users to automation in three steps: planning with the XITO Designer, procurement of components via the XITO Marketplace and commissioning using the XITO Builder - all without any programming knowledge. This manufacturer-independent modular system makes it easier to get started with robotics and helps to overcome the shortage of skilled workers and cost pressure.