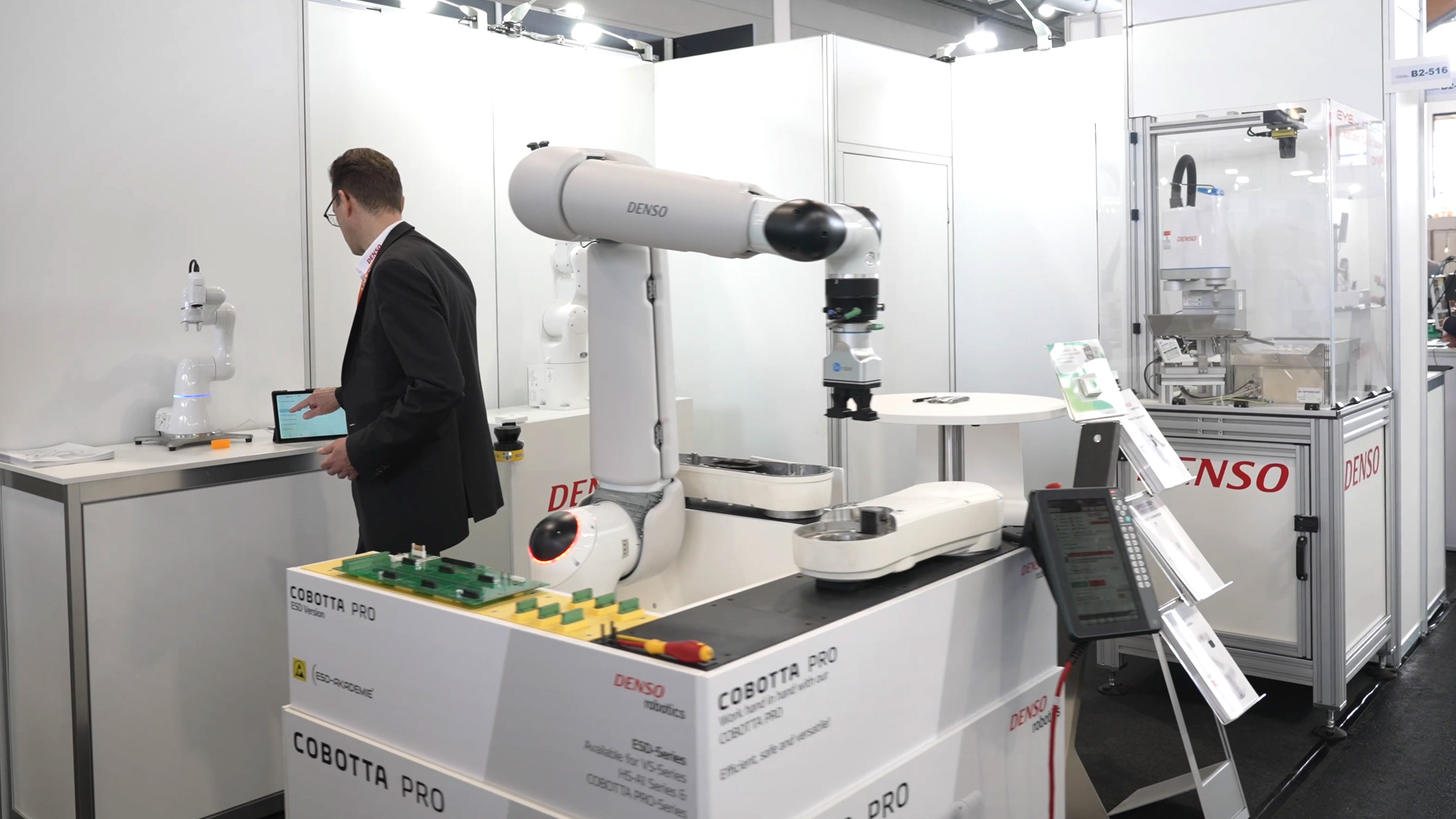

DENSO COBOTTA PRO: High-precision human-robot collaboration for industry

The COBOTTA PRO from Denso is a collaborative robot that combines the performance of an industrial robot with the safety of a cobot. It performs precise tasks such as inserting electronic components into circuit boards or holding heavy components during assembly processes. Thanks to its sensitivity and adaptive force control, it adapts optimally to different manufacturing processes. It can work slowly in safe mode or at a speed of up to 2.5 meters per second for particularly fast and efficient processes. In areas such as electronics production, the automotive industry and intralogistics, it enables optimum cooperation between man and machine by taking over monotonous or strenuous tasks and thus creating ergonomic working conditions.

High-precision motion control and dynamic adjustment

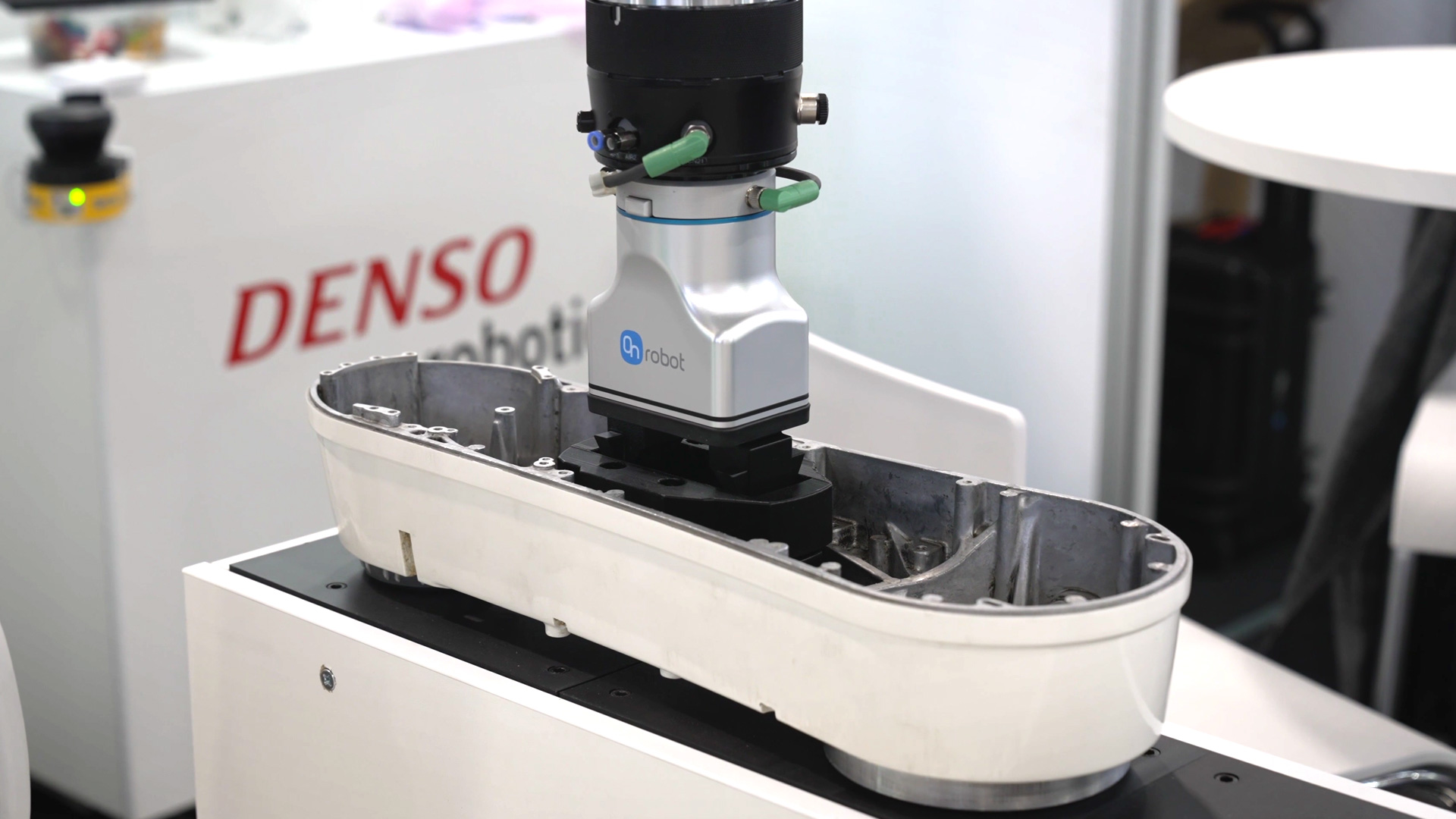

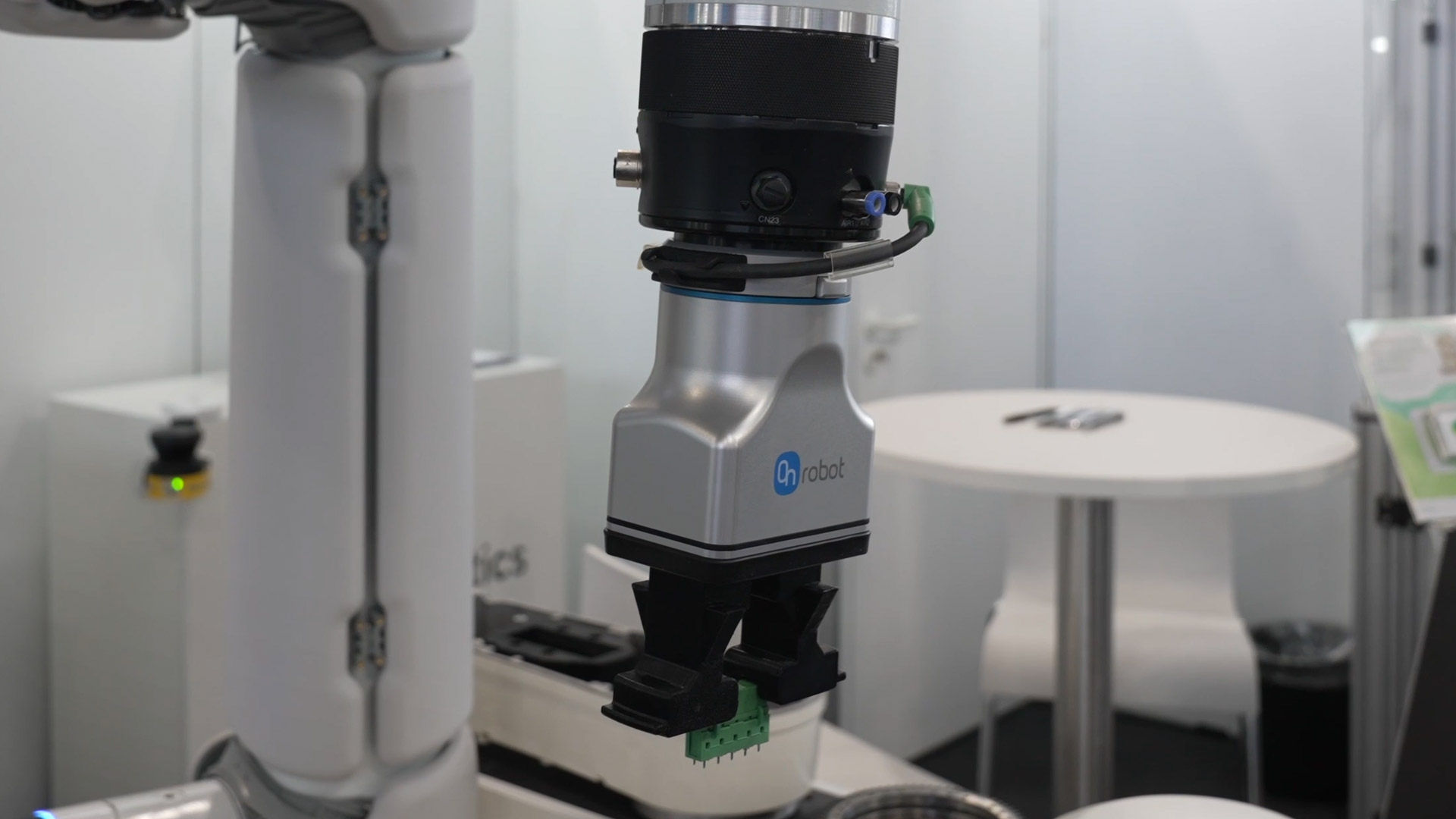

The COBOTTA PRO is characterized by its intuitive control and sensitive motion control. It adapts flexibly, especially in electronics production, where millimeter-precise positioning is required. Its advanced sensor technology allows it to detect resistance and adjust its own movement in real time. For example, it can precisely align gear wheels or insert components exactly into an assembly device. This high level of precision reduces error rates and ensures consistently high quality in production.

In assembly, the robot works hand in hand with humans: While it holds the workpiece securely, the human carries out complex assembly steps. This flexible interaction reduces physical strain and enables efficient production with high repeat accuracy. Particularly demanding processes that require manual adjustment and force adaptation benefit from the COBOTTA PRO's ability to react to the smallest changes with sensitive precision.

Quick and easy programming via teach-in

A special feature of the COBOTTA PRO is its simple programming. Thanks to the teach-in function, motion sequences can be learned in just a few minutes. The robot arm can be guided directly by hand to define the desired positions, which are then saved at the touch of a button. The control system implements the programmed sequences immediately, so that even users without extensive programming knowledge can quickly adapt the robot to specific tasks.

This intuitive control system lowers the barriers to entry for companies looking to integrate automation solutions into their manufacturing processes for the first time. At the same time, it enables rapid adaptation to new production requirements without the need for extensive training or complex software configurations. This means that even smaller batch sizes can be produced economically and flexible automation solutions can be implemented.

Economical automation with modular expansion options

The investment costs for a COBOTTA PRO start at under €30,000, depending on the area of application and additional peripherals. In addition to the robot itself, grippers, conveyor systems and sensor modules can be integrated to create customized automation solutions. The total cost of a complete robot cell varies between €50,000 and €100,000, depending on its complexity. As the COBOTTA PRO can be flexibly integrated into existing production lines, there are no high adaptation costs. Companies benefit from rapid amortization thanks to increased efficiency and reduced error rates. Thanks to the possibility of converting the robot for different tasks, it can be used in a variety of ways and contributes to the sustainable optimization of production processes.

Overall, the COBOTTA PRO offers a powerful, economical and adaptable automation solution that is suitable for both simple handling tasks and complex manufacturing processes. With its intuitive control, flexible application options and high precision, it sets new standards in human-robot collaboration and facilitates entry into industrial automation.

What does DENSO do?

DENSO Robotics is a global supplier of industrial robots and part of the DENSO Corporation. The company develops compact 4-axis SCARA as well as 5- and 6-axis robots for a wide range of automation applications. The robots are designed for high speed and precision and are used in areas such as assembly, processing, inspection and machine operation. With many years of experience, DENSO focuses on technological innovation and high quality standards.