Evosoft - Innovative software solutions for production automation

At All About Automation, Evosoft will be presenting advanced software solutions that create transparency in production facilities and make processes more efficient. The focus is on the integration, structuring and standardization of production data in order to fully exploit optimization potential. With modern dashboards, assistance systems and intelligent algorithms, Evosoft supports companies in analyzing, simulating and improving their production processes.

Data analysis and assistance systems for greater transparency in production

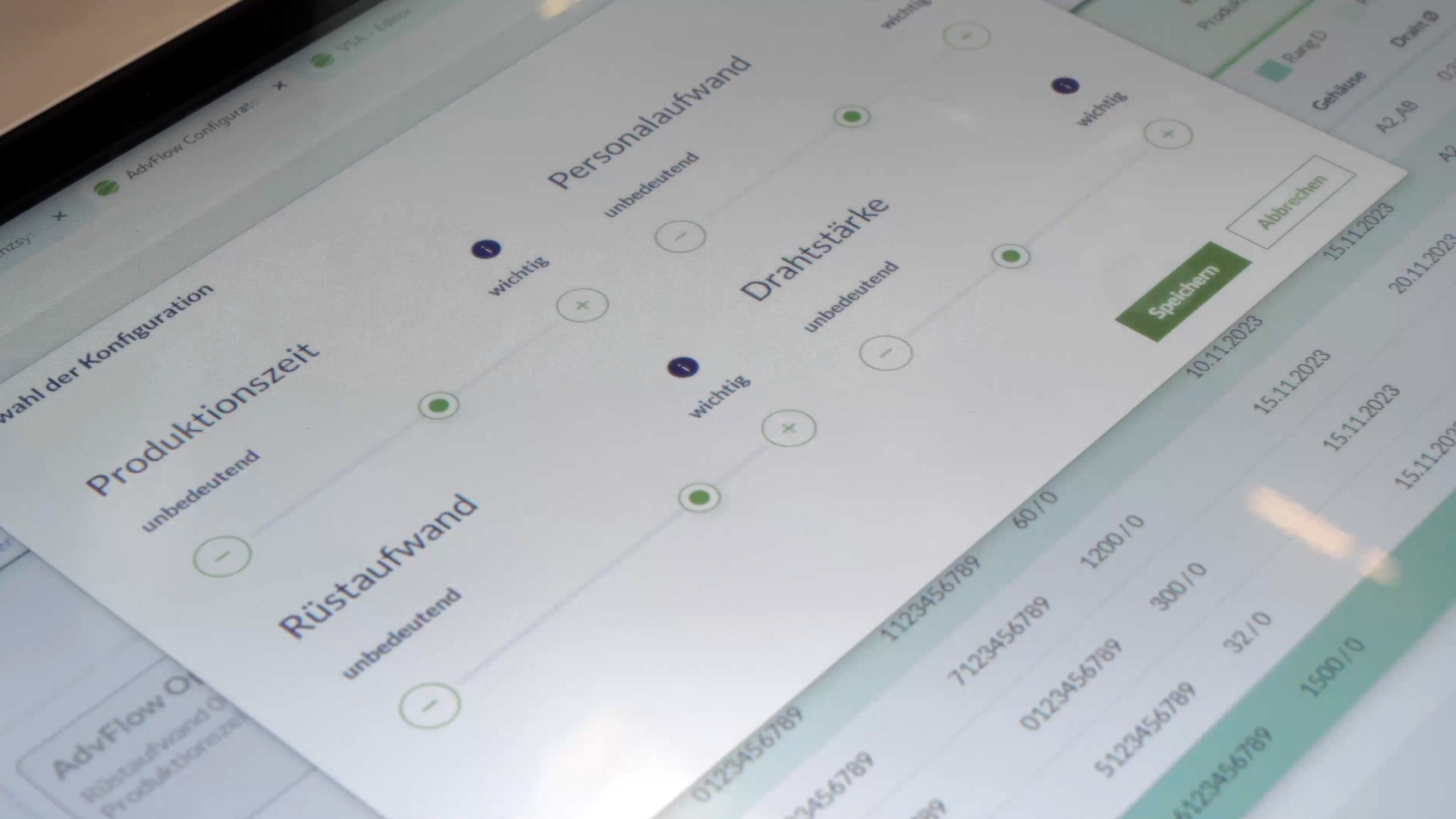

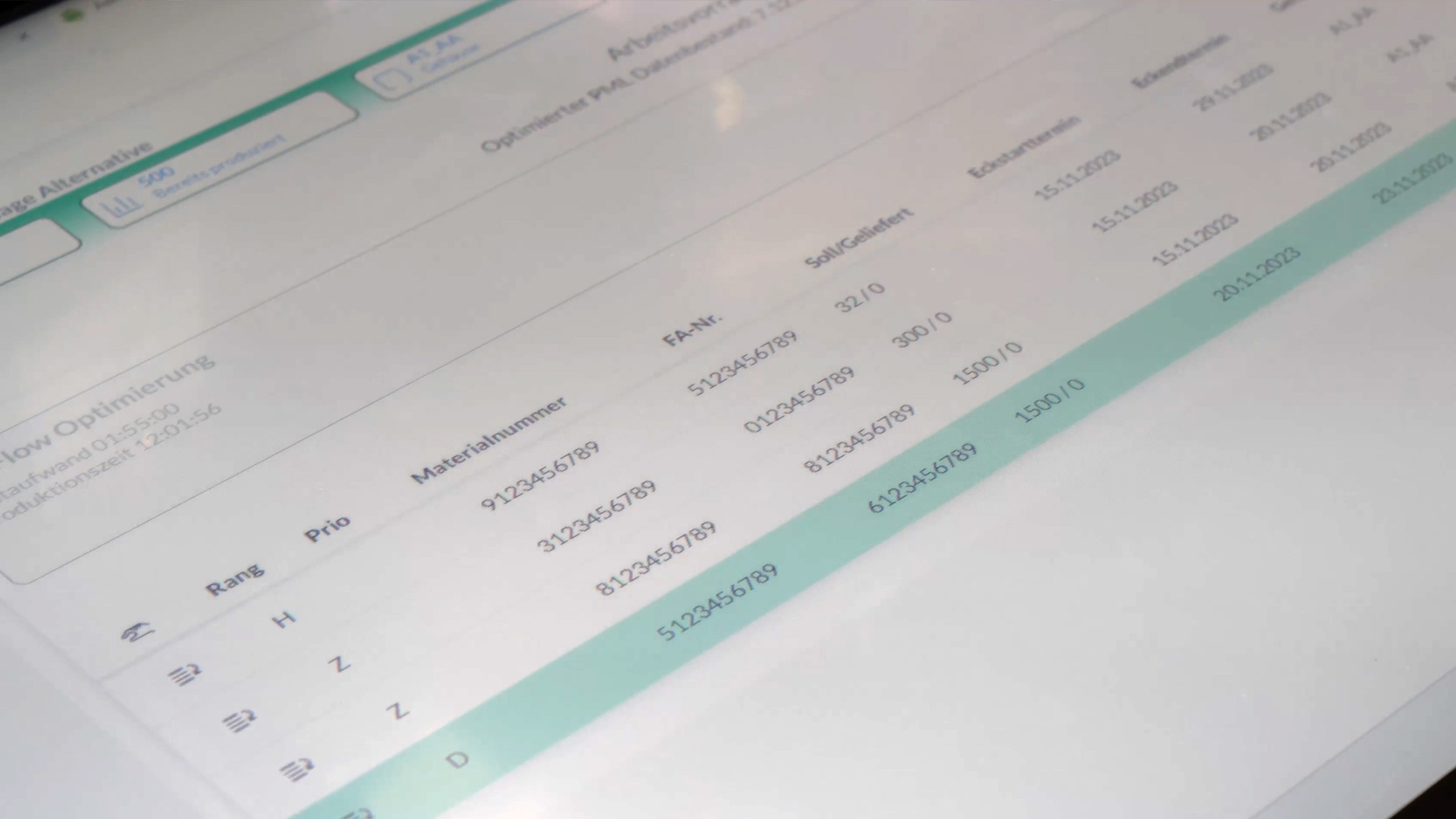

A central aspect of Evosoft solutions is data integration and visualization. Production data is presented in powerful dashboards to provide managers with a comprehensive overview of all relevant key figures. The information obtained serves as a basis for decision-making processes and enables data-based optimization of production processes. Assistance systems for workers and production managers are also used. These solutions help to avoid operating errors, optimize maintenance processes and monitor workflows in real time. Intelligent algorithms are used to identify optimization potential at an early stage so that production downtimes can be reduced and resources used more efficiently.

Simulations and virtual commissioning for efficient production planning

Evosoft offers simulation solutions for the entire production chain, from the planning of new production lines to the virtual commissioning of plants. With the help of modern factory simulations, companies can test various scenarios before making any physical changes. Simulation plays a particularly important role in plant planning:

- Optimization of production lines: Should a second line be integrated or are other layouts more efficient?

- Analysis of routes and material flows: How do vehicles and machines move through production?

- Calculation of cycle times and set-up processes: How can processes be designed more efficiently to avoid production bottlenecks?

By using virtual commissioning, the software can be tested before the actual start of production. This reduces sources of error, shortens the actual commissioning time and ensures that employees can be trained at an early stage, even before the physical system is up and running.

Comprehensive advice - from planning to service

Evosoft not only assists companies with the implementation of new software solutions, but also offers comprehensive support from the initial analysis through to ongoing operation. Experienced technical consultants develop customized solutions that are geared towards the specific challenges of the customer. The service chain includes:

- Consulting and needs analysis based on real production requirements

- Software development and engineering for customized solutions

- Commissioning and test runs to validate the systems

- Training and long-term support for sustainable process optimization

With this comprehensive approach, Evosoft ensures that companies retain full control over their production processes and can continuously benefit from technological advances.

What does evosoft do?

evosoft GmbH is an international IT company headquartered in Nuremberg and a wholly owned subsidiary of Siemens AG. Since 1995, evosoft has been developing customized software, IT and automation solutions for various industries, including the discrete industry, process industry, transport & logistics, mobility and healthcare. With locations in Germany and Hungary as well as nearshore partners in Romania and Turkey, the company supports customers worldwide in the digital transformation and integration of IT and OT systems. The range of services includes individual software development, digital store floor management solutions, material flow optimization, factory simulation and IT-OT connectivity.