Automation is playing an increasingly important role in industrial production, especially when it comes to handling workpieces and materials. Schmalz develops state-of-the-art gripping systems that are specially designed for integration into robotic solutions. With the combination of electric cobot pumps, flexible changing systems and intelligent vacuum grippers, the company provides an efficient, adaptable and intuitive automation solution for a wide range of industries.

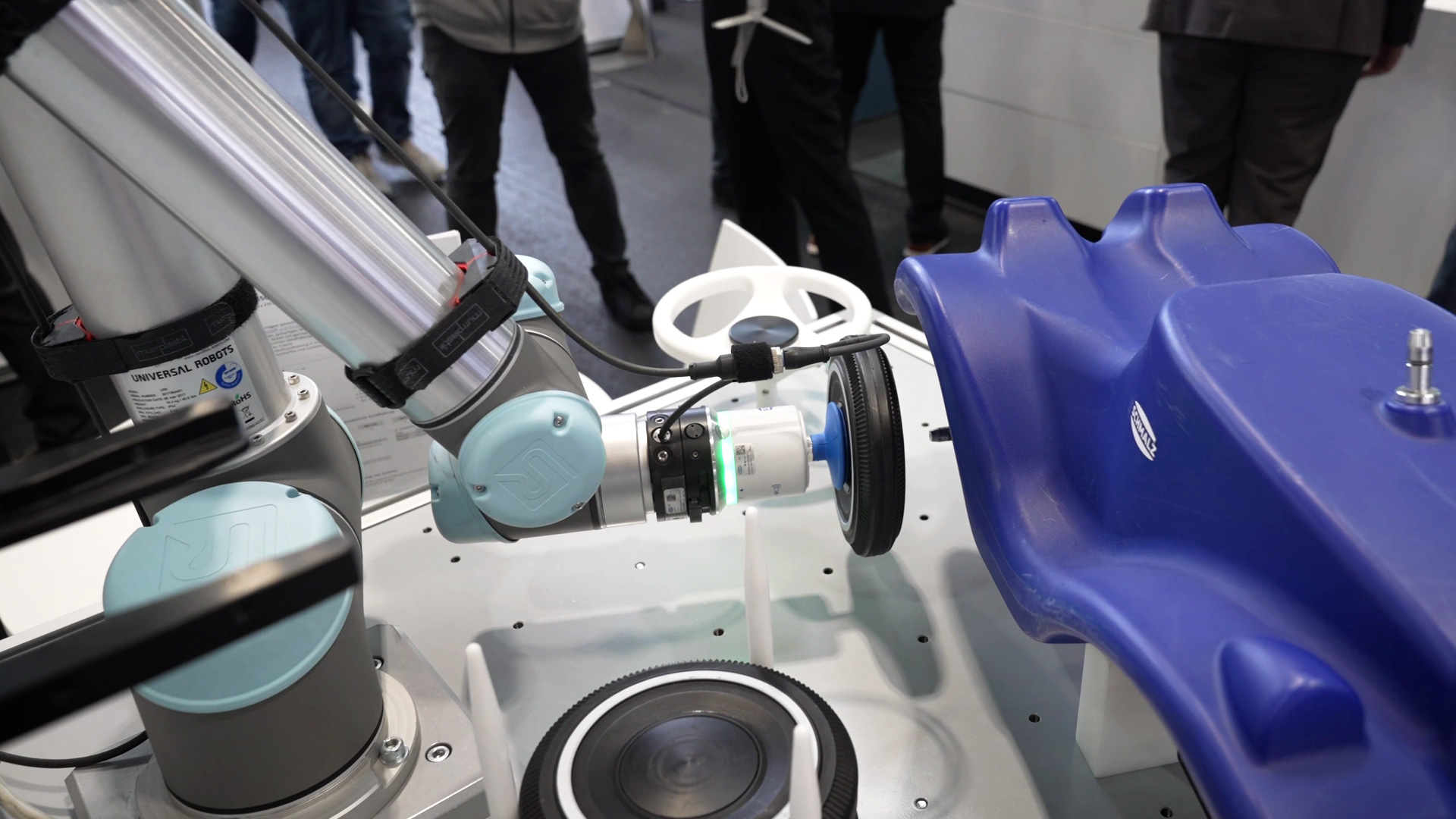

Schmalz relies on electric cobot pumps that can be seamlessly connected to robot arms, enabling quick and easy integration. A particular highlight is the Match change system, which offers a standardized mechanical and pneumatic interface. This allows different grippers to be exchanged quickly and flexibly in order to implement a variety of assembly processes with different components. Programming a cobot is intuitive and simple. Positions can be saved and controlled with digital signals, allowing a gripping process such as "suction on, suction off" to be carried out effortlessly. The result is an easy-to-use automation solution that does not require in-depth programming knowledge.

A special innovation in the Schmalz range is the FMG matrix gripper, which ensures maximum flexibility for complex workpieces. Each individual suction cup can be specifically controlled and activated. This functionality is particularly helpful when it comes to components with recesses, holes or variable interfaces. In combination with artificial intelligence and image processing systems, the system automatically recognizes which suction cups need to be activated for a specific workpiece. This ensures that only the stable surfaces of the workpiece are sucked in and no vacuum losses occur - an advantage that is particularly noticeable with laser-cut sheet metal parts or other components with complex geometries.

In addition to industrial applications, Schmalz also offers specialized gripping systems for food processing. One example of this is a mechanical gripper that works with vacuum and compressed air to grip sensitive foods such as fish, meat or vegetables safely and hygienically. These grippers are made of food-safe materials such as stainless steel and are optimized for easy cleaning and high hygiene standards. They are ideal for companies that process and pack products without packaging, for example in poultry processing or fruit and vegetable packaging. Thanks to their modular design, different gripper shapes and sizes can be combined to flexibly handle different products.

The investment costs for a complete robotic cell depend heavily on the requirements. High-precision systems with complex grippers and high load capacity can cost between 50,000 and 100,000 euros. At the same time, however, there are also low-cost solutions that combine robot arms with simple gripper systems for around EUR 5,000. In this way, compact automation solutions can be implemented from around 10,000 euros. The choice of the right solution depends on factors such as precision, cycle time and durability. This gives companies the opportunity to choose a customized automation solution that meets their individual requirements and budget specifications.

Schmalz offers highly flexible and powerful gripping systems that can be seamlessly integrated into existing automation processes. Whether intelligent vacuum technology for complex workpieces, hygienic solutions for the food industry or cost-efficient low-cost robotics - the technologies from Schmalz enable efficient and economical automation that can be individually adapted to the respective production requirements.

J. Schmalz GmbH, based in Glatten, is a leading provider of vacuum technology and ergonomic handling systems. The company develops solutions for automation, manual handling and clamping technology, which are used in various industries such as logistics, the automotive industry, electronics and furniture production. In addition to vacuum components and gripping systems, Schmalz also offers innovative energy storage solutions. With a global presence in around 70 countries, Schmalz supports its customers in making processes more efficient and sustainable.