KUKA expands its portfolio: Mobile robotics for flexible automation

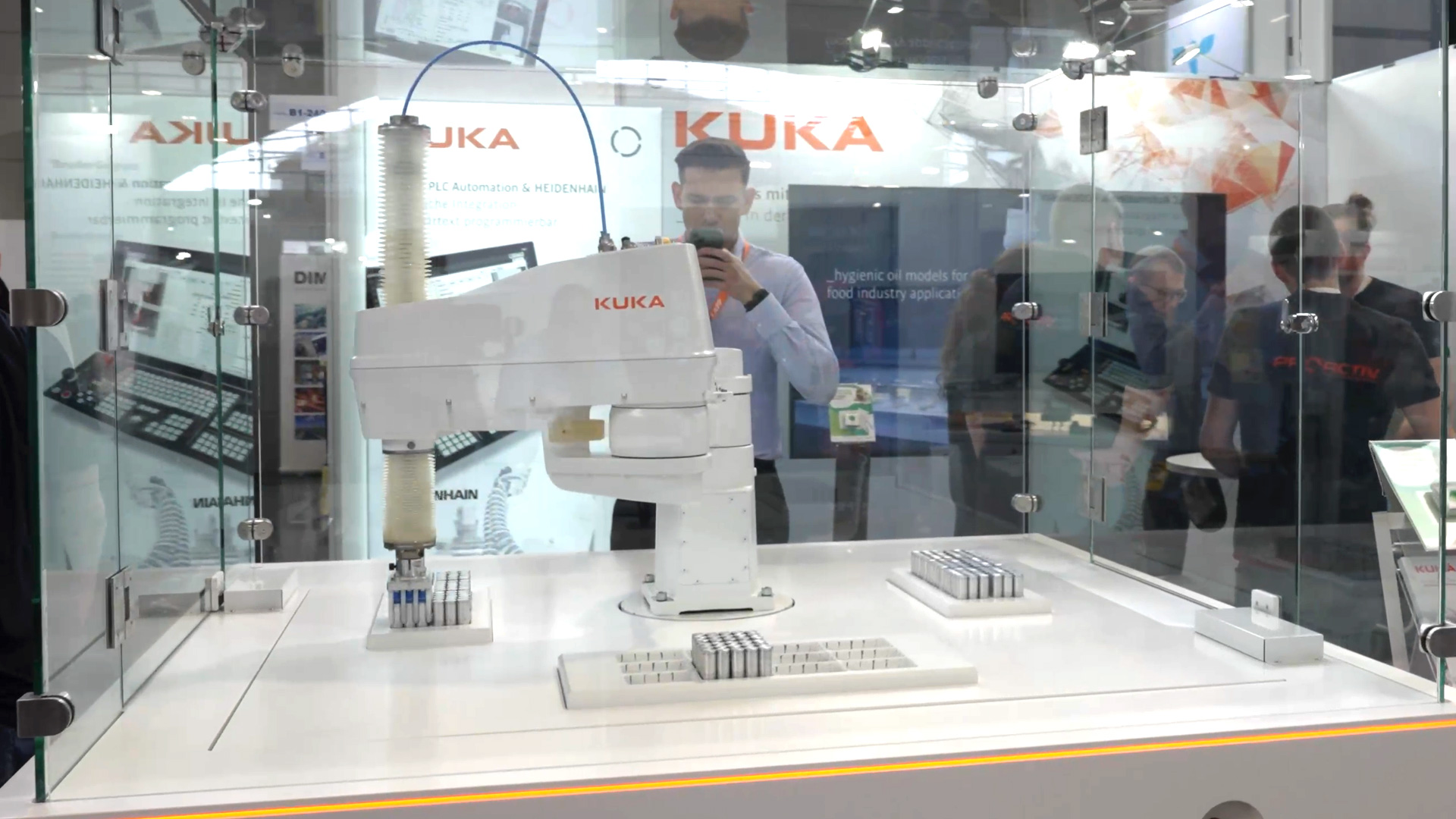

KUKA, known for its industrial robots, is increasingly opening up new fields of application and expanding its range in mobile robotics. The automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) enable efficient material flows in logistics and production. With powerful loading capacities and a flexible platform design, the systems can be individually adapted. The combination of intelligent navigation and central fleet management makes them a forward-looking solution for companies that want to automate their processes.

Autonomous navigation and intelligent control

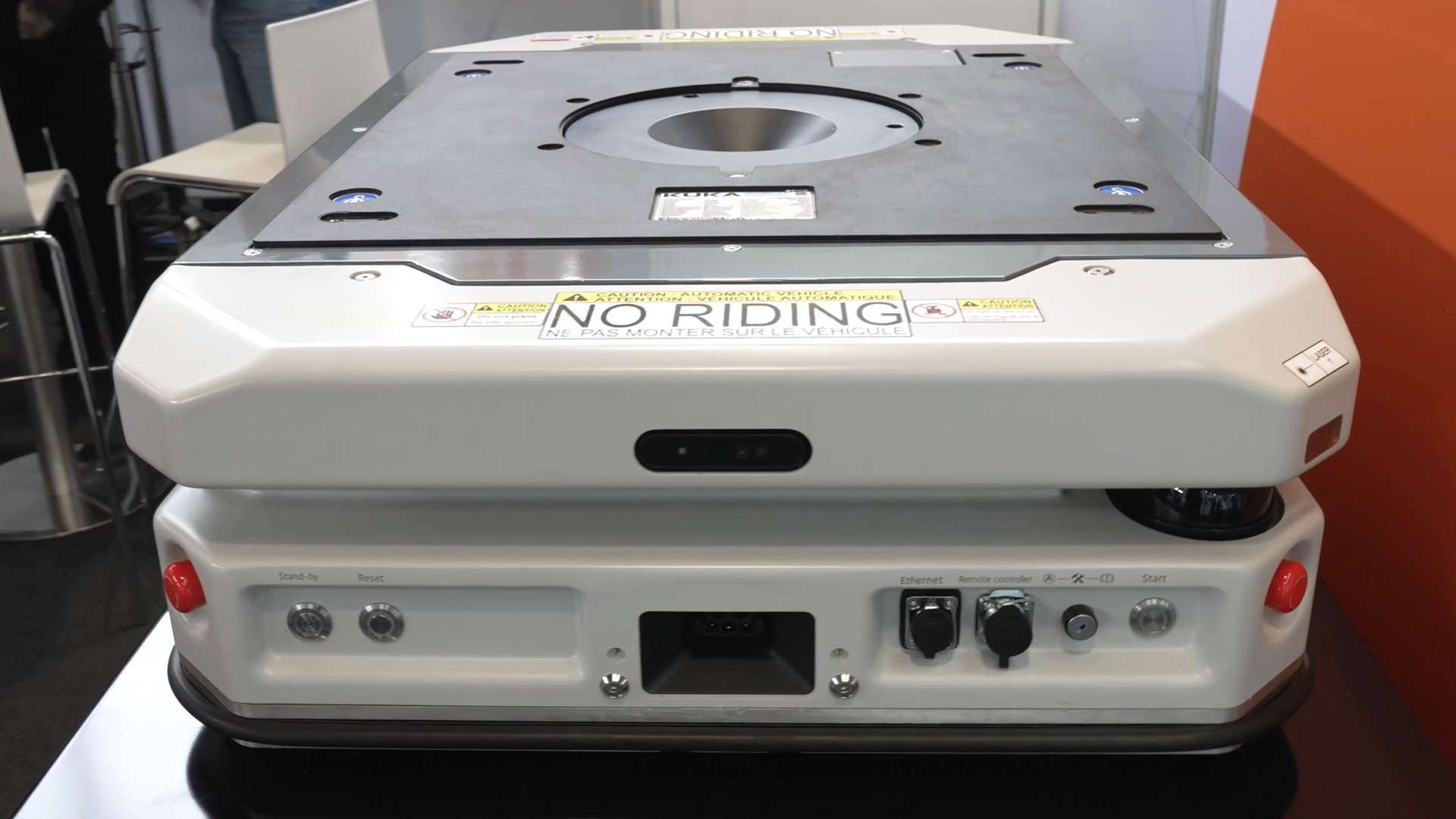

The mobile robot systems from KUKA capture their environment map once and then orient themselves independently with the help of laser scanners. This enables them to move safely and efficiently in dynamic environments. The central, web-based fleet management system coordinates several AMRs and ensures smooth process control. Commands are transmitted digitally and the robots adapt their routes flexibly. This allows them to perform tasks such as transporting materials and loading production lines independently.

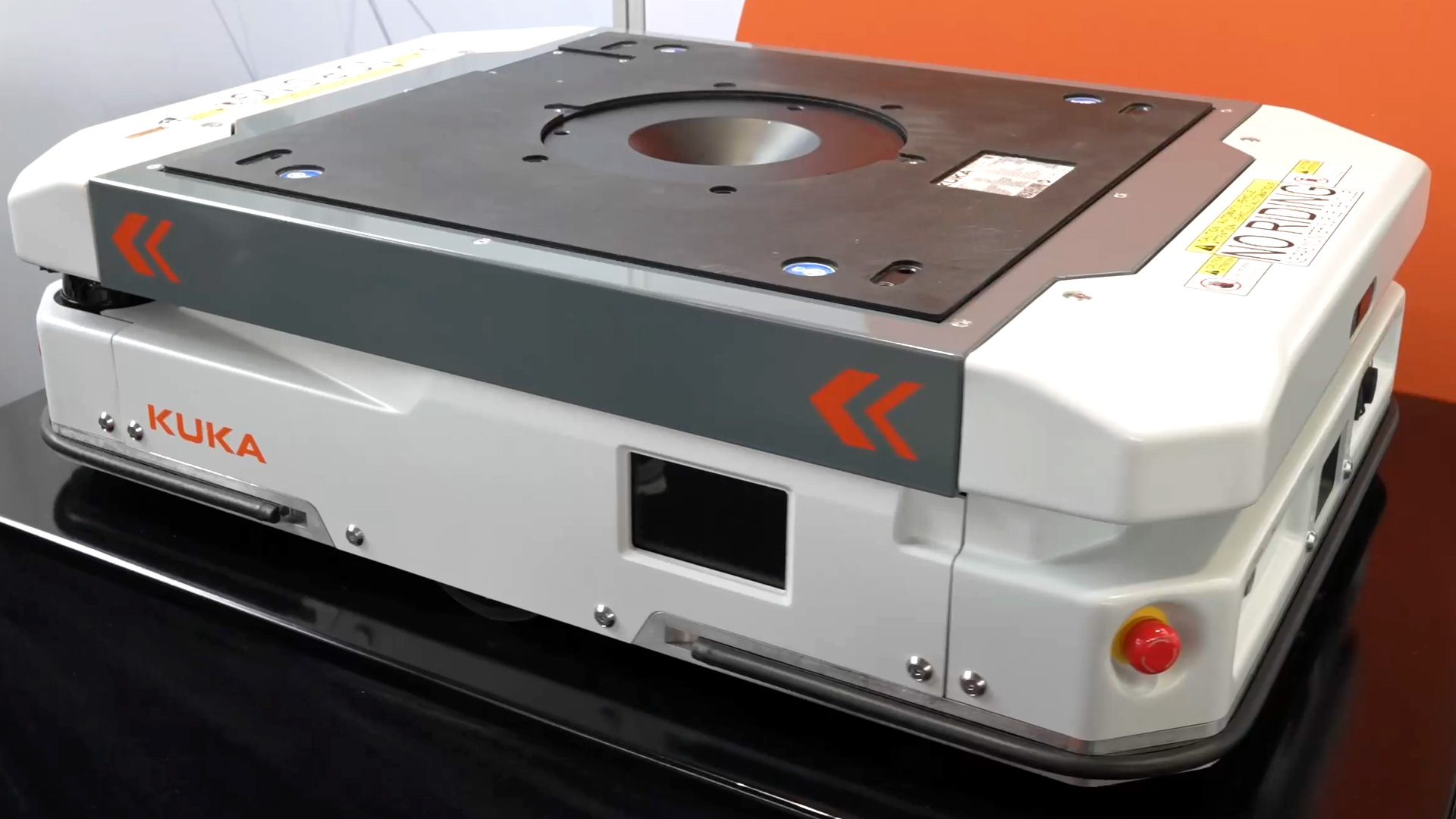

Modular platform for versatile applications

The platform of the mobile robots is designed so that various superstructures can be easily integrated. Standardized drill holes allow flexible mounting of forks, conveyor belts or other specialized components. This allows the systems to be adapted precisely to the respective operational requirements. Whether for in-house goods transportation, automatic material supply or the replacement of conventional forklift trucks - the mobile solutions from KUKA offer a wide range of possible applications and can be seamlessly integrated into existing production environments.

Powerful payloads and high travel speeds

KUKA offers various models with payloads from 600 to 3000 kilograms. Depending on the model, the mobile robots can travel at a speed of up to two meters per second when unloaded, while the speed is reduced to 1.5 meters per second when fully loaded, depending on the weight class. The investment costs vary according to the load capacity, with the most powerful models costing up to 100,000 euros. The continuous expansion of the portfolio enables companies to choose needs-based solutions for different transportation requirements.

Future-proof automation with KUKA

Through the consistent further development of its mobile robotics solutions, KUKA ensures that companies can make their production and logistics processes more efficient. The combination of autonomous navigation, flexible fleet management and modular adaptability makes the systems a worthwhile investment in the future of automation. With continuous innovations and a constantly growing product portfolio, KUKA remains an important player in the industrial transformation.

What does KUKA do?

KUKA AG is an international automation group headquartered in Augsburg, Germany. The company offers intelligent automation solutions for various industries, including the automotive industry, electronics, metal processing and consumer goods. Its range of services includes the development and production of industrial robots, manufacturing cells and turnkey systems as well as networked production solutions. With locations in over 50 countries worldwide, KUKA supports its customers in optimizing their production processes through innovative technologies and services.