AMTEC Kistler GmbH is a leading manufacturer of machines and automation solutions for the dosing and coating of liquid to pasty media. Its blank coating systems are used particularly in the automotive industry for the precise application of forming lubricants. AMTEC also offers special solutions for cavity preservation and oil supply for vehicle engines. Thanks to continuous technological developments, the company has achieved a high standard of process reliability and flexibility.

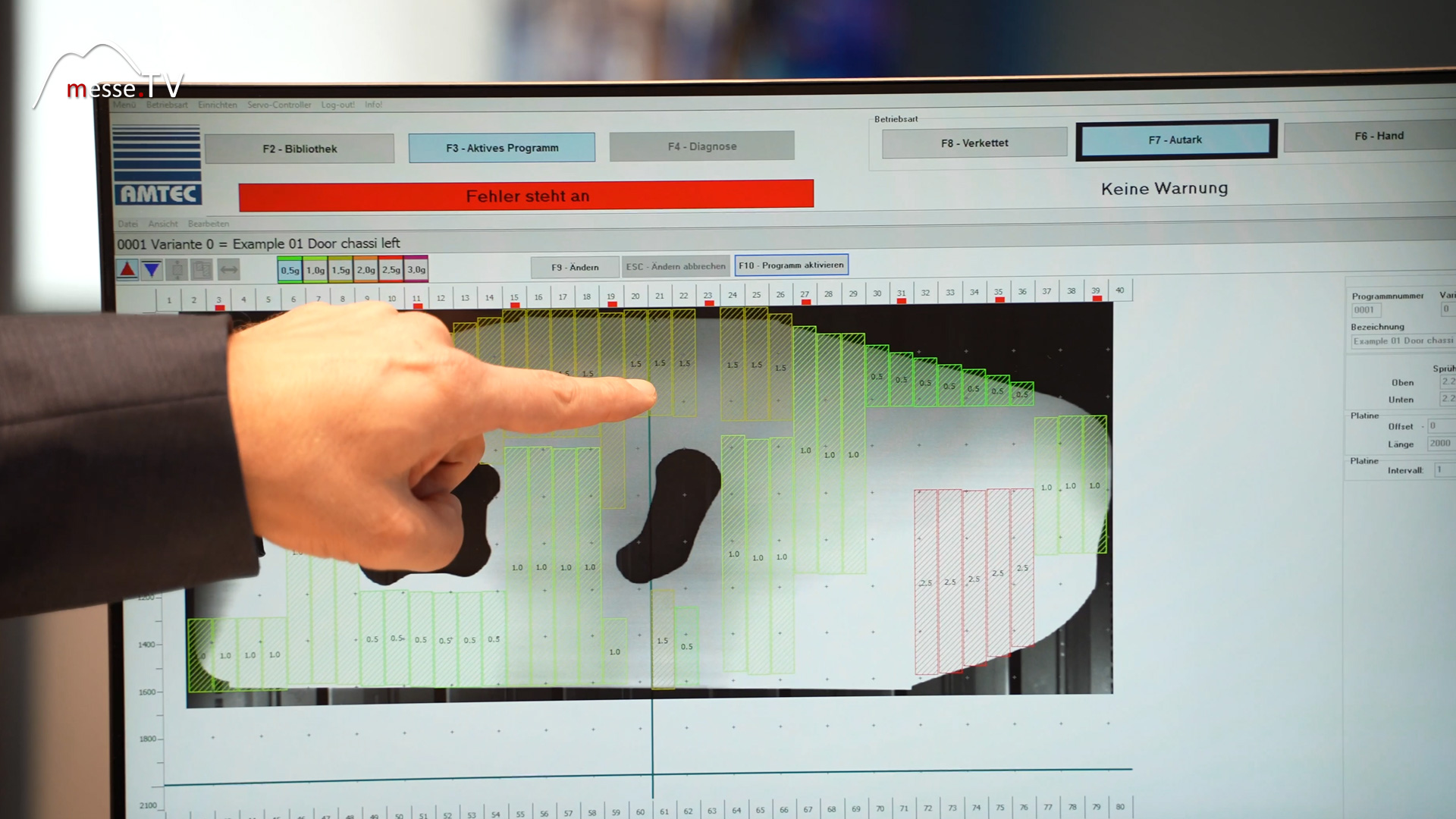

The oiling machine presented here is specially designed to lubricate blank blanks precisely and evenly before they are formed in a press line. The device, equipped with 80 valves, distributes the oil to the blanks in a controlled manner to enable optimum processing and forming. The 40 valves at the top and 40 valves at the bottom play a central role in ensuring a uniform coating that is tailored to the specific requirements of the forming process. The integration of automatic self-monitoring makes it easy for the operator to check the condition of the valves at any time and ensure that the amount of oil is applied precisely.

An outstanding feature of this machine is the innovative self-monitoring technology, which continuously checks the condition of each individual valve. As the operator cannot manually check whether all valves are spraying the correct amount of oil, the machine performs this function independently. Sensors are used to ensure that the oil is distributed exactly according to the programmed settings. If a valve, such as valve 21, does not function correctly and sprays an incorrect quantity, this condition is immediately detected and displayed in the diagnostics. This enables the operator to take immediate action to ensure that the blanks are evenly lubricated and to avoid production stoppages.

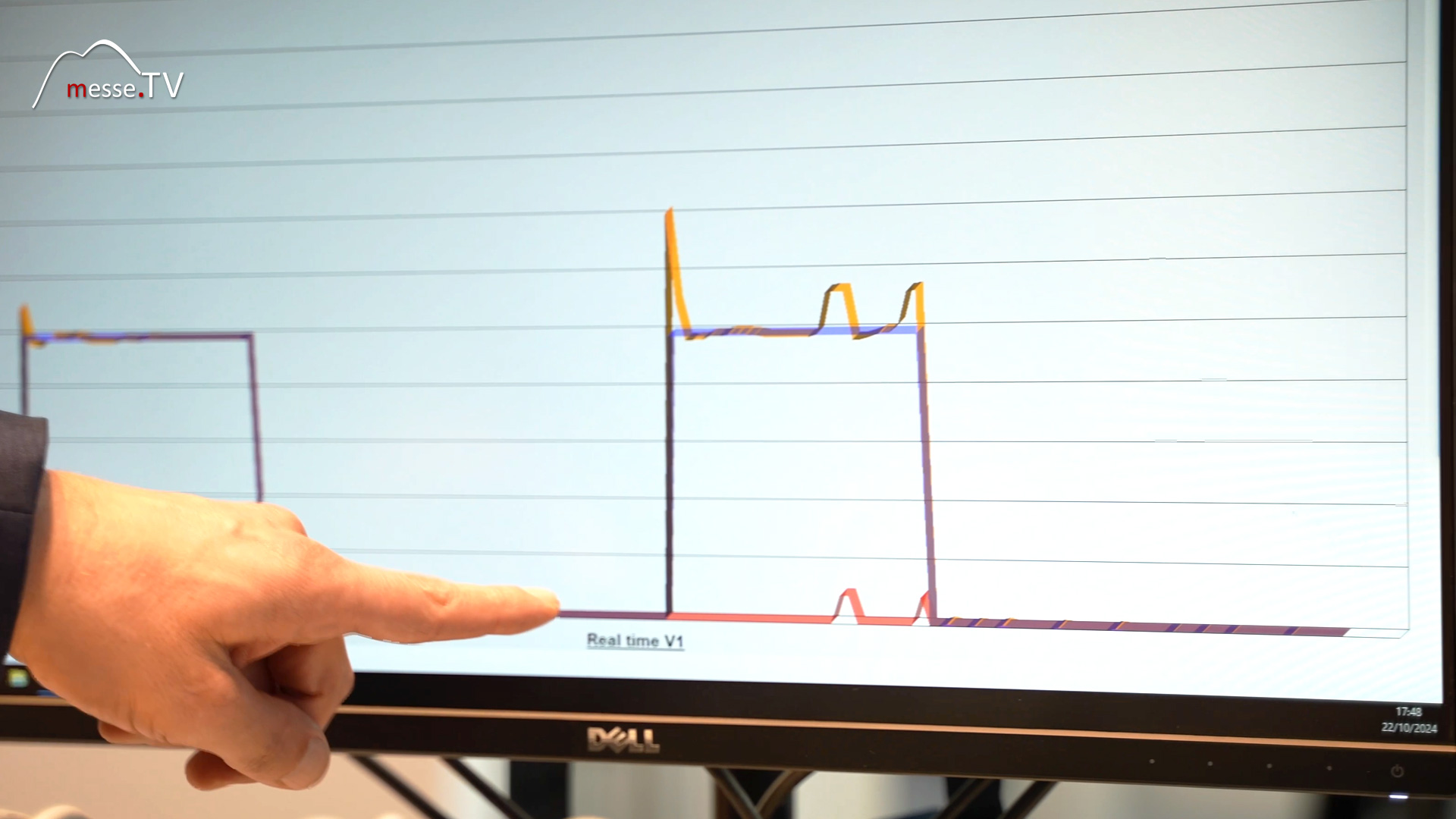

Another technological highlight is the control of the spray needle without tactile movement. Instead, the dosing of the oiling is precisely controlled by a magnetic linear drive, known as a voice coil. This technology makes it possible to move the spray needle precisely and quickly without mechanical wear, optimizing the longevity and accuracy of the oiling machine. This magnetic control enables the valves to be opened and closed with millimeter precision, resulting in extremely even and reliable lubricant distribution. With this combination of self-monitoring and precise control, the machine offers a pioneering solution for the automotive and metalworking industries to sustainably increase efficiency, reliability and product quality.