Perndorfer Maschinenbau specializes in the development of waterjet cutting systems and special machines for various industries. The durable and modular cutting systems are characterized by high precision and productivity. In addition to customized machines, Perndorfer also offers comprehensive service and contract manufacturing services, such as turning, milling and welding. The Austrian family business stands for innovation and quality, which are valued internationally.

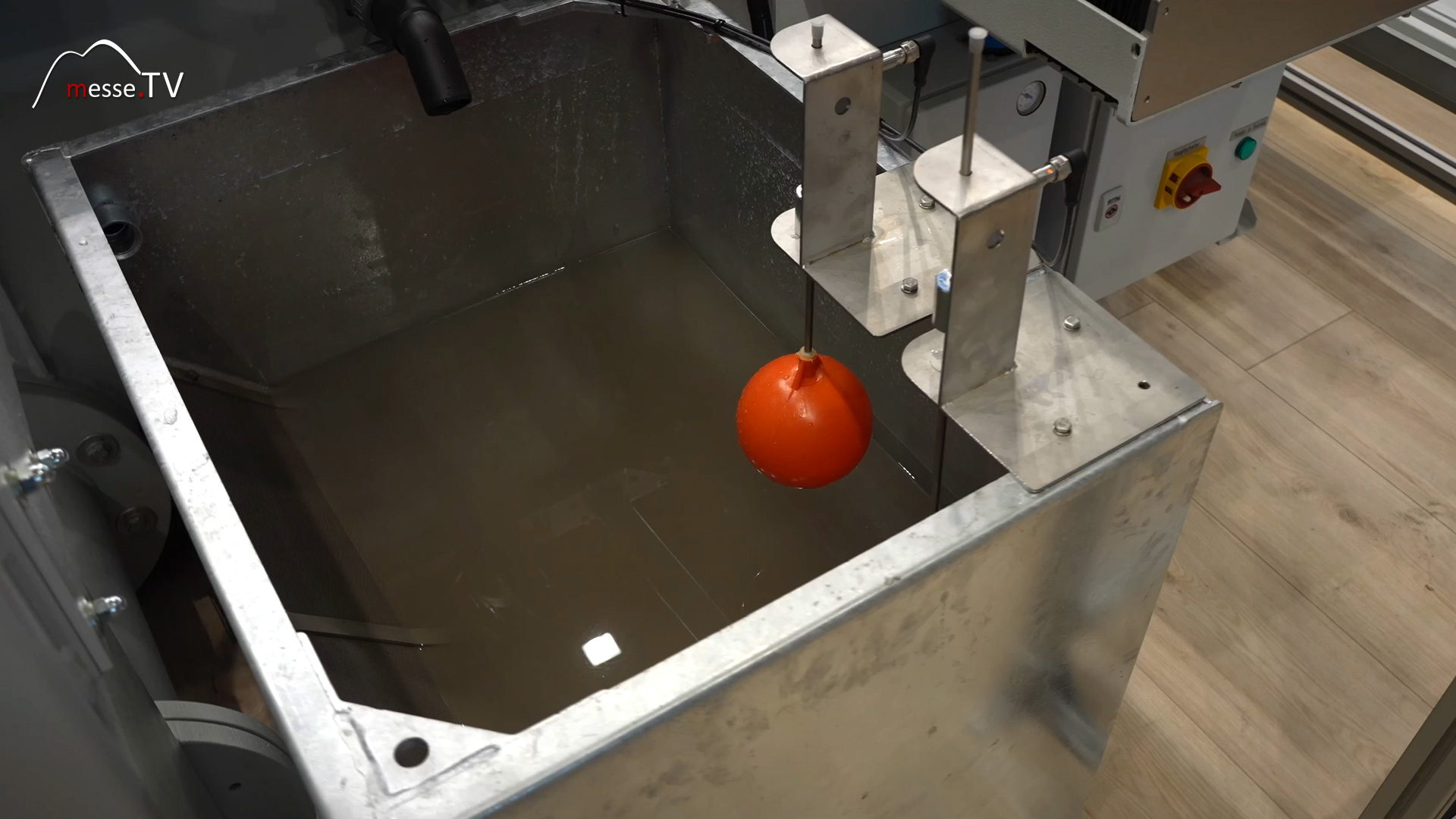

Waterjet cutting is a precise process that requires large quantities of water to cut materials such as stainless steel, aluminum and plastic. The water is contaminated by abrasion and the garnet sand used. Perndorfer has developed a solution that optimally recycles the water and protects the environment. With the help of an innovative water recycling system, impurities and particles are reliably filtered out of the cutting water. This technology separates out even the smallest particles down to a size of 0.02 micrometers, so that clean water remains in the cycle and the sewer system remains free of dirty water and microplastics.

Recycling water during the cutting process not only conserves resources, but also prevents the release of microplastics that can be produced when cutting plastics. Thanks to effective filtering, the system removes even the finest microplastic particles from the water before it is fed back into the high-pressure pump. If it is necessary to drain the cutting water, it can be passed through the filter system again and only then disposed of in an environmentally friendly manner. In this way, Perndorfer makes an important contribution to environmental protection that meets the increasing demands for sustainability in the industry.

Perndorfer has been developing high-quality solutions for waterjet cutting since 1991 and has established itself as a pioneer in this field. The company's own high-pressure pump, which impresses with its exceptional energy efficiency, is just one of the many patented innovations. Perndorfer is now expanding its portfolio with the new water recycling system, which both reduces operating costs and enables sustainable work processes. This latest technology in waterjet cutting once again demonstrates the innovative strength and environmental responsibility that have characterized Perndorfer for decades.