Bernd Siegmund GmbH is a leader in the manufacture of welding tables, clamping systems and positioners for metalworking. Its high-quality products are characterized by precision and flexibility and are used in various industries worldwide. Siegmund offers a wide range of modular welding table systems and accessories that make the work process more efficient and safer. With over 25 years of experience, the company stands for quality and innovative solutions in welding technology.

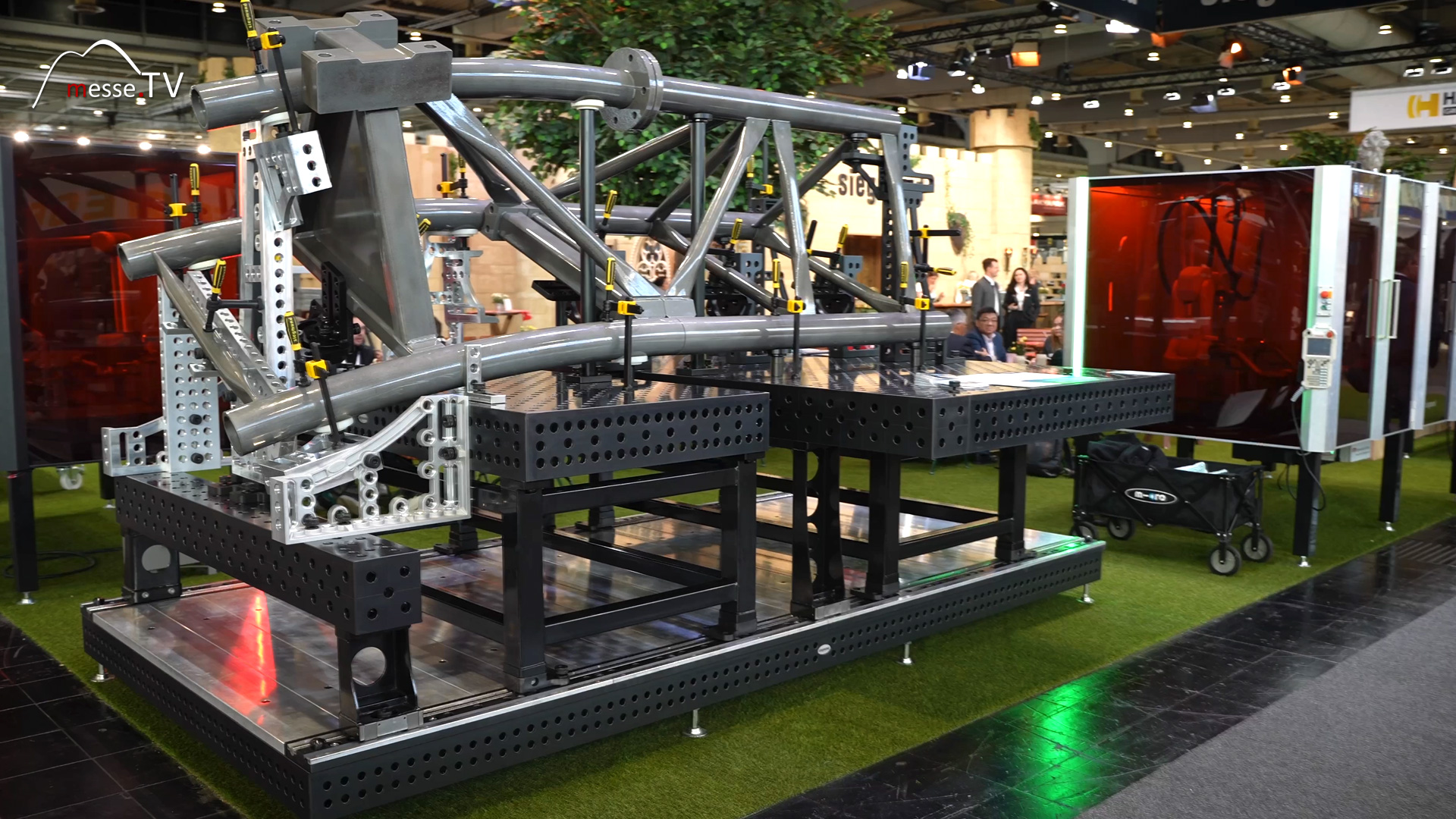

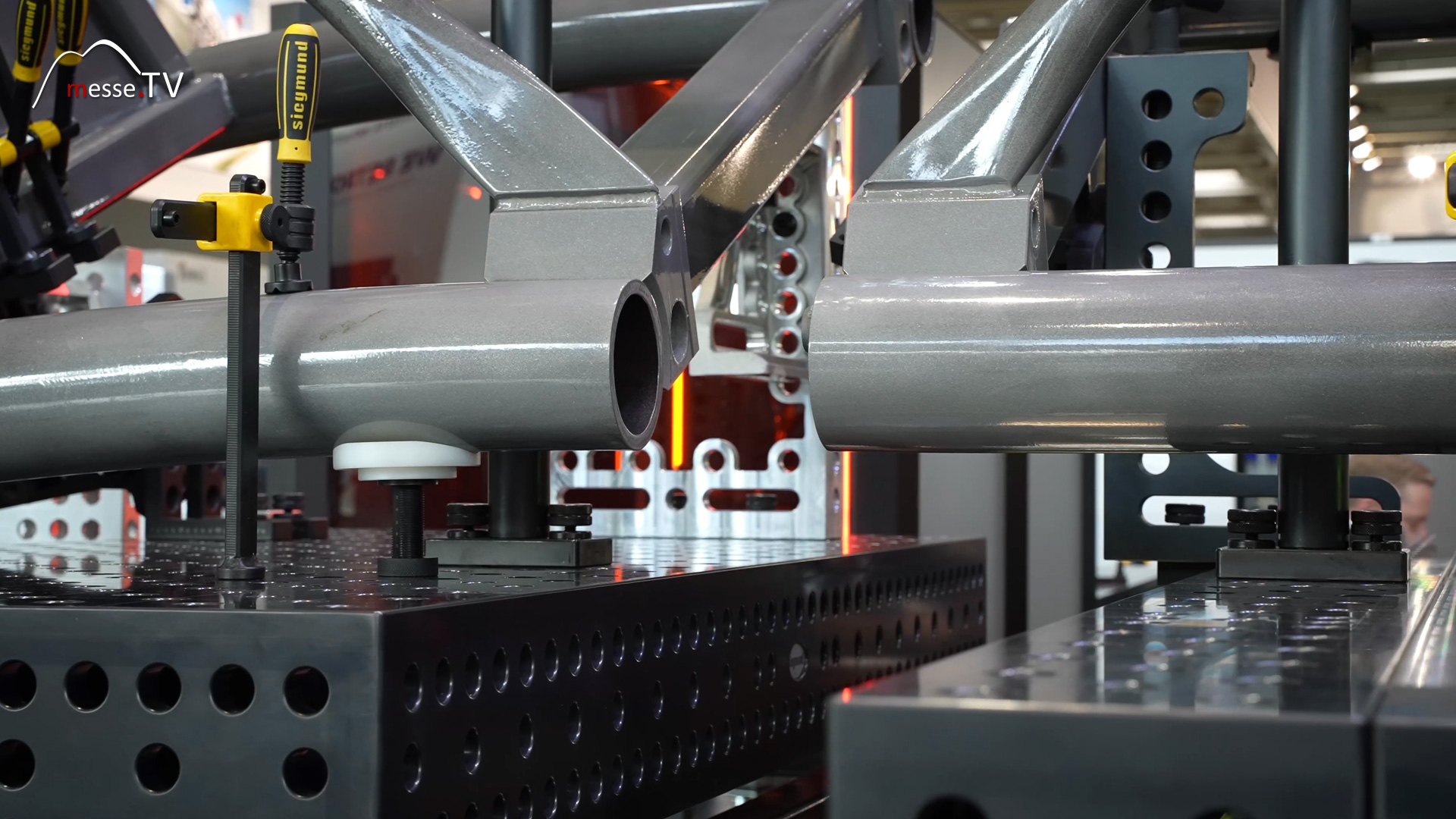

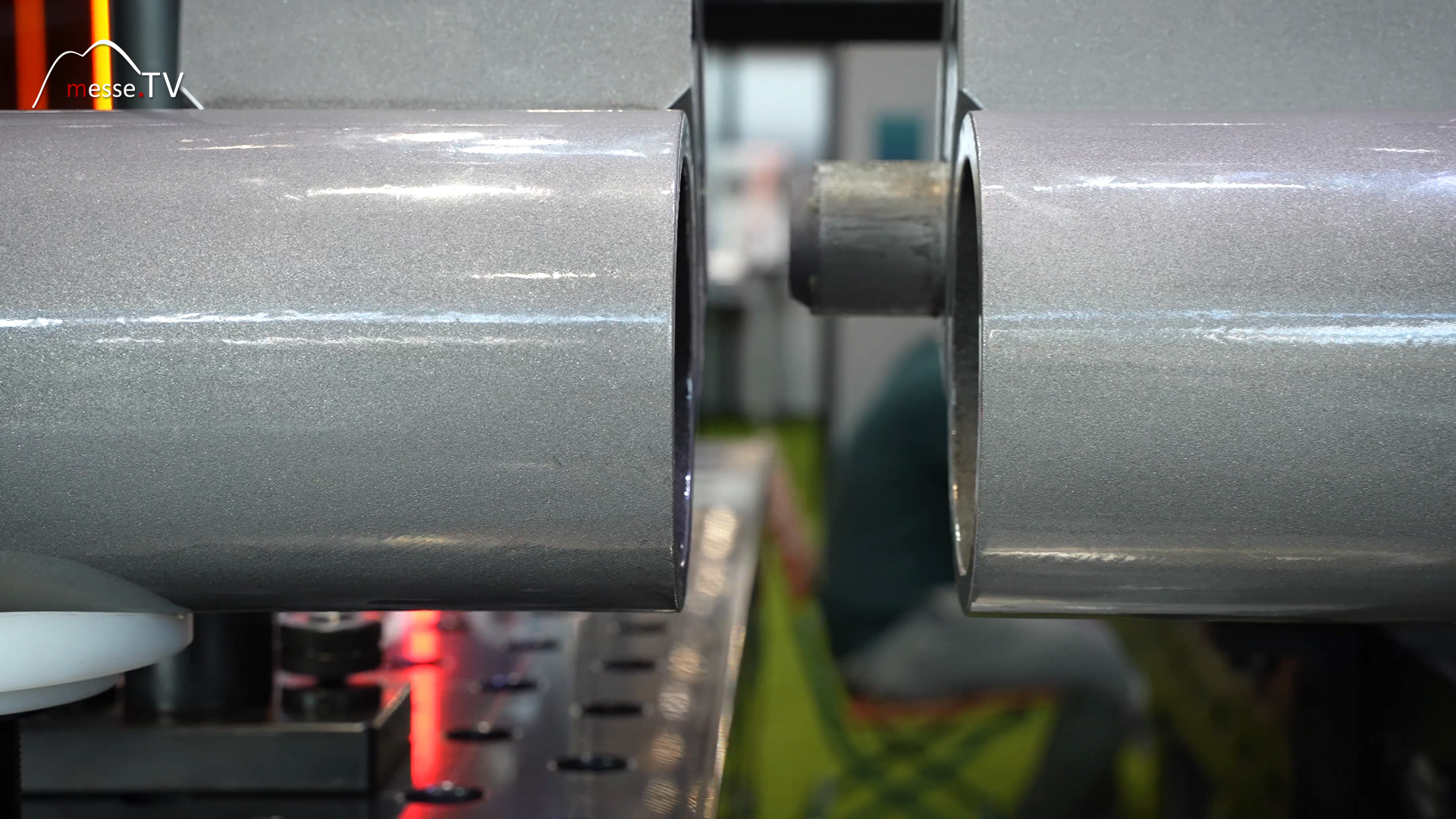

Siegmund demonstrates how even huge metal structures can be welded and processed efficiently. Behind the scenes of the roller coasters at Europapark, a special rail system enables the precise connection of large components, such as the complex triangular profiles that safely support free forms such as loops or other ride maneuvers. Siegmund's rail system is characterized by its precision down to the millimetre, regardless of whether the components are a few meters or even up to 100 meters apart. This accuracy enables simple and precise handling, even with materials weighing several tons - with minimal effort.

Siegmund masters the challenge of precisely joining large metal parts with an innovative rail design that meets the highest standards of precision. The highlight: thanks to a special hole system, all components remain in place with millimeter precision, even with extreme dimensions. Despite a total weight of up to 3 tons, the individual components can be moved effortlessly and joined together with absolute precision, which is essential for the complex requirements of modern theme park attractions.

In addition to large projects, Siegmund also offers welding tables for private customers. These tables are smaller and more affordable, starting at a size of 1x1 meter and can reach up to 4x2 meters. This means that a suitable solution is available for every application - whether for professional workshops or the discerning hobbyist. Prices start at around 600 euros, offering a flexible entry into professional welding work.