WEBER is an experienced machine manufacturer that offers solutions in the fields of sanding technology, extrusion, additive manufacturing and automation. With over 100 years of expertise, WEBER develops innovative and customized machines for industries such as woodworking, metalworking and plastics processing. The company places particular emphasis on quality, efficiency and the integration of modern technologies to increase the productivity of its customers. Over 20,000 WEBER machines are in use worldwide, supported by comprehensive services and technological advancements.

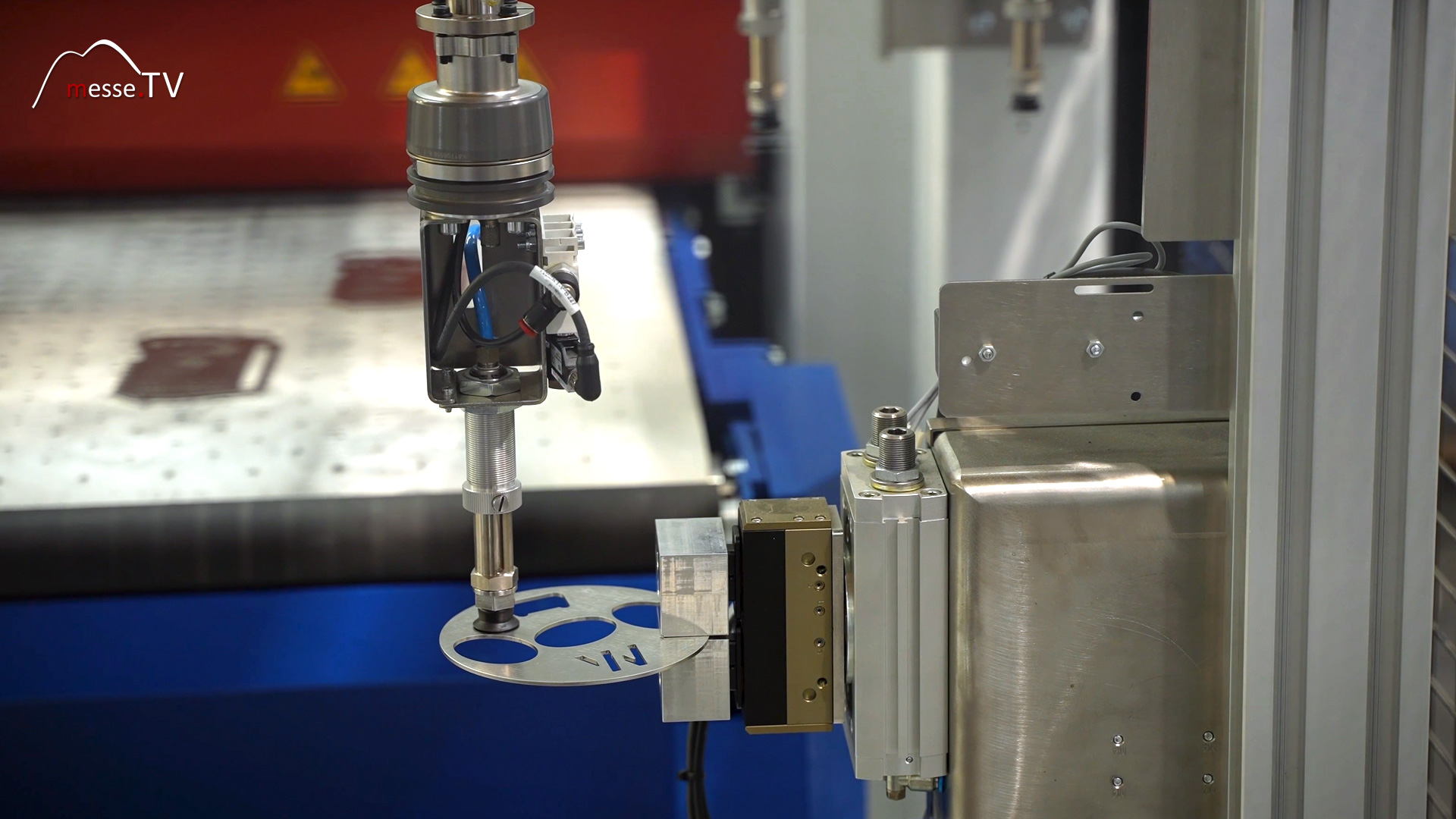

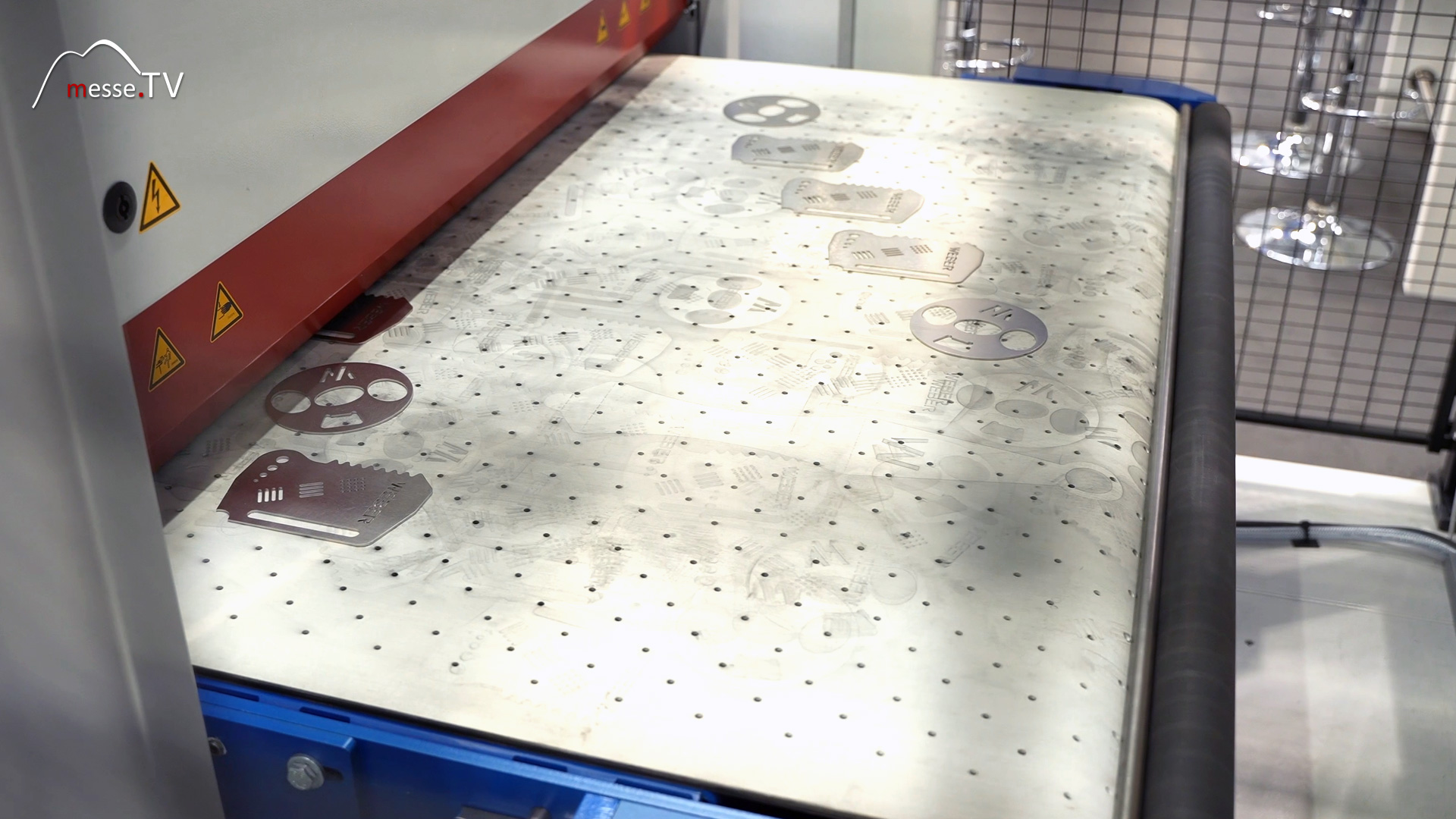

Weber will be presenting a highly innovative, teach-free machine loading system for robot cells at the trade fair. This solution enables laser-cut or punched parts to be fed fully automatically onto pallets within the robot cell. Using a high-precision 3D camera, the system recognizes the individual parts, scans them and calculates the centre of gravity in order to determine the ideal gripping point for the robot. The robot then grips the components and supports the production process by loading the deburring machine. A special feature of this technology is the optimized loading of the machine, which ensures that the abrasive belt and tools are used evenly across the entire width, guaranteeing high efficiency and a long service life for the materials. The robot cell recognizes both unmixed and randomly distributed parts without the need for training - a user with smartphone experience can easily operate the system.

The true innovation of the NOVA telescopic coil tongs lies in their intelligent control system. This not only calculates the load weight of the coil, but also determines the actual service life of the tongs. By continuously monitoring the load, the user can precisely plan the maintenance cycles and service intervals. This enables maximum efficiency, whether in full-load operation or in three-shift operation with lighter loads. A clear touch display shows the remaining service life of the tongs so that the user always has an overview of the current operating data.

Weber, a traditional company from Upper Franconia in northern Bavaria, has been developing grinding machines for metal workpieces for over 100 years and deburring machines for metalworking for over 30 years. With around 500 employees, Weber combines a high level of vertical integration in mechanical engineering - from mechanical design and programming to production, everything is done in-house. Thanks to this comprehensive expertise and the new fully automatic loading and destacking solutions, Weber offers machines that help companies with staff shortages in particular to automate simpler tasks and optimize production processes.