Peter Prinzing GmbH specializes in the development and manufacture of sheet metal processing machines as well as barn de-stacking technology. Its portfolio includes machines for beading, flanging, rounding and cutting sheet metal, which can be operated both manually and fully automatically. The company also offers customized solutions for the agricultural sector to efficiently remove manure from stables. With over 60 years of experience, Prinzing stands for quality and reliability in industry and agriculture.

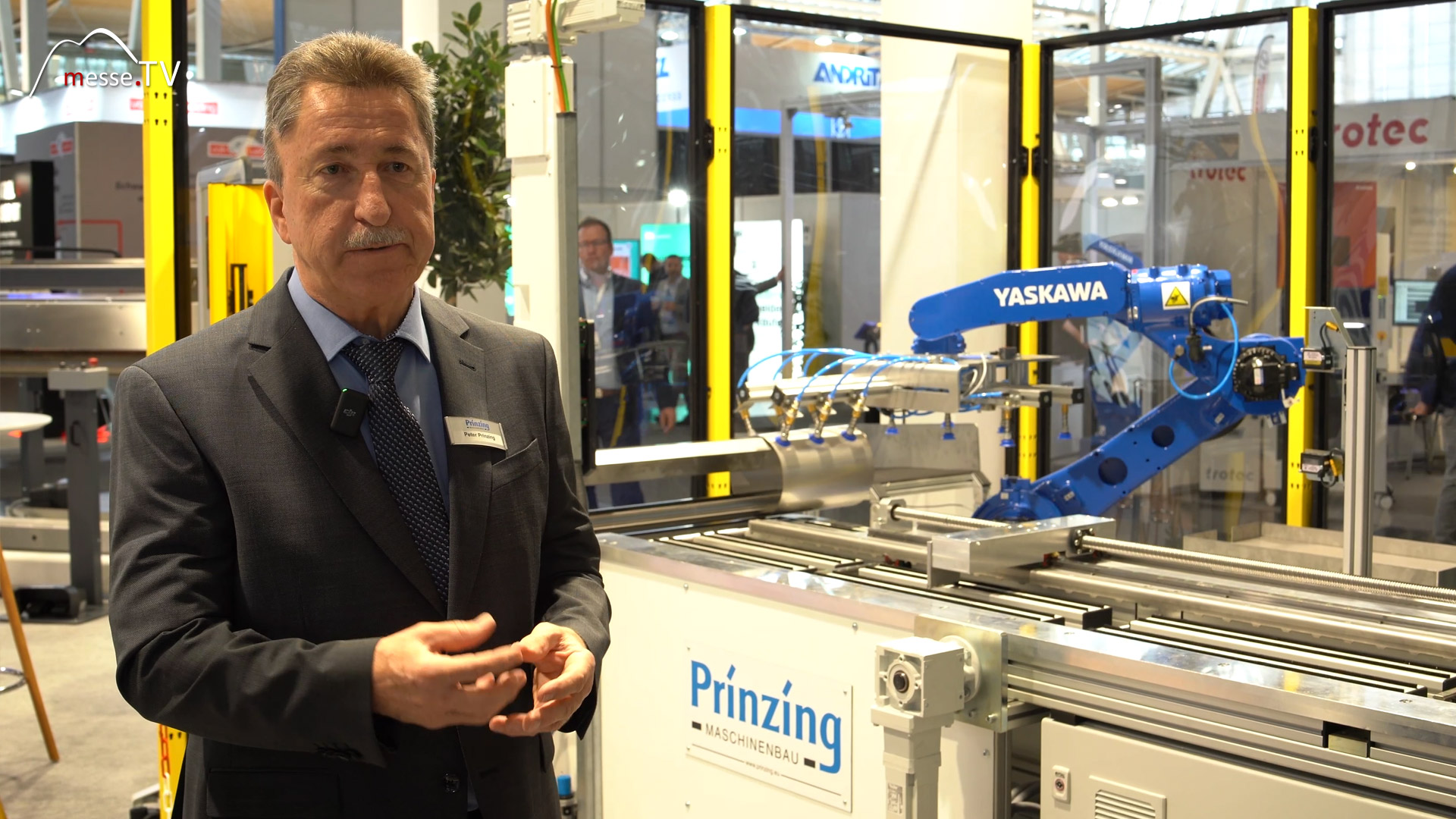

Prinzing presents an innovative solution in sheet metal processing with its latest 4-roll rounding machine. This machine stands out due to its automatic control and the integration of robot technology for flexible production. Unlike previous systems, which were limited to fixed movements, the robot-controlled system enables great flexibility in the processing of workpieces. This means that a variety of parts can be produced in different shapes and sizes.

One of the outstanding features of the 4-roll rounding machine is its extremely flexible control system. Workpieces from the smallest to the largest diameter can be processed precisely with just one program change. In addition, a large number of programs can be saved, which further increases the machine's adaptability. This is particularly advantageous for companies that need to produce a wide range of workpieces without having to schedule long changeover times.

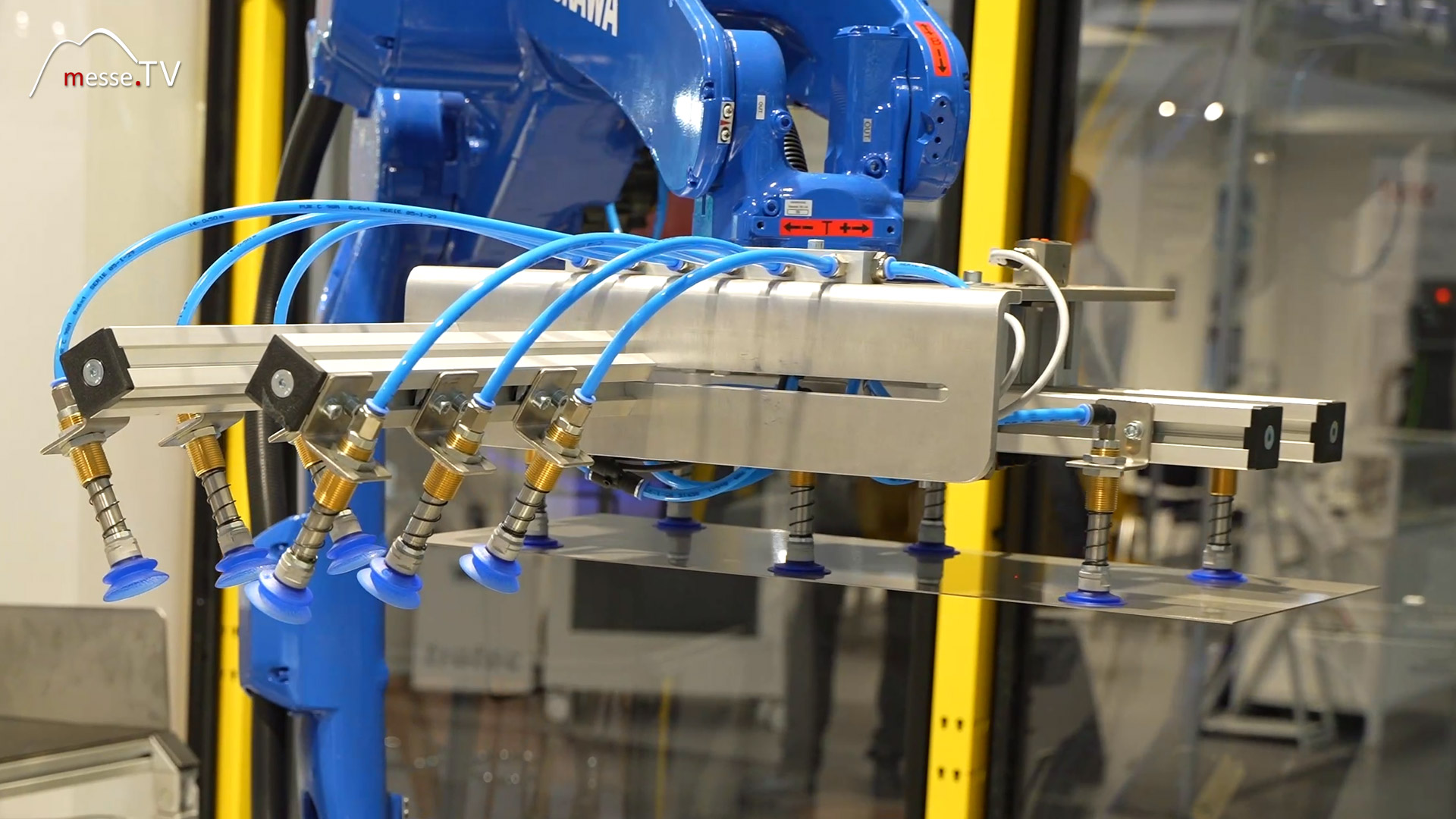

The machine can not only be used flexibly in terms of shapes and sizes, but is also able to process sheets of different thicknesses. In combination with a flexible gripper, the machine offers a wide range of possible applications. For customers, this means a high degree of adaptability to different production requirements, making it particularly interesting for companies with changing sheet metal processing requirements.