EuroBLECH 2024: The Leading Event for Sheet Metal Working Technology

Euroblech is the world's leading trade fair for sheet metal working technology and takes place in Hanover from October 22 to 25. It offers companies and trade visitors a platform to discover the latest innovations and technologies from the fields of sheet metal working, mechanical engineering and automation. Here you will find new articles on Euroblech 2024 every day.

Future trends in sheet metal processing: focus on automation and sustainability

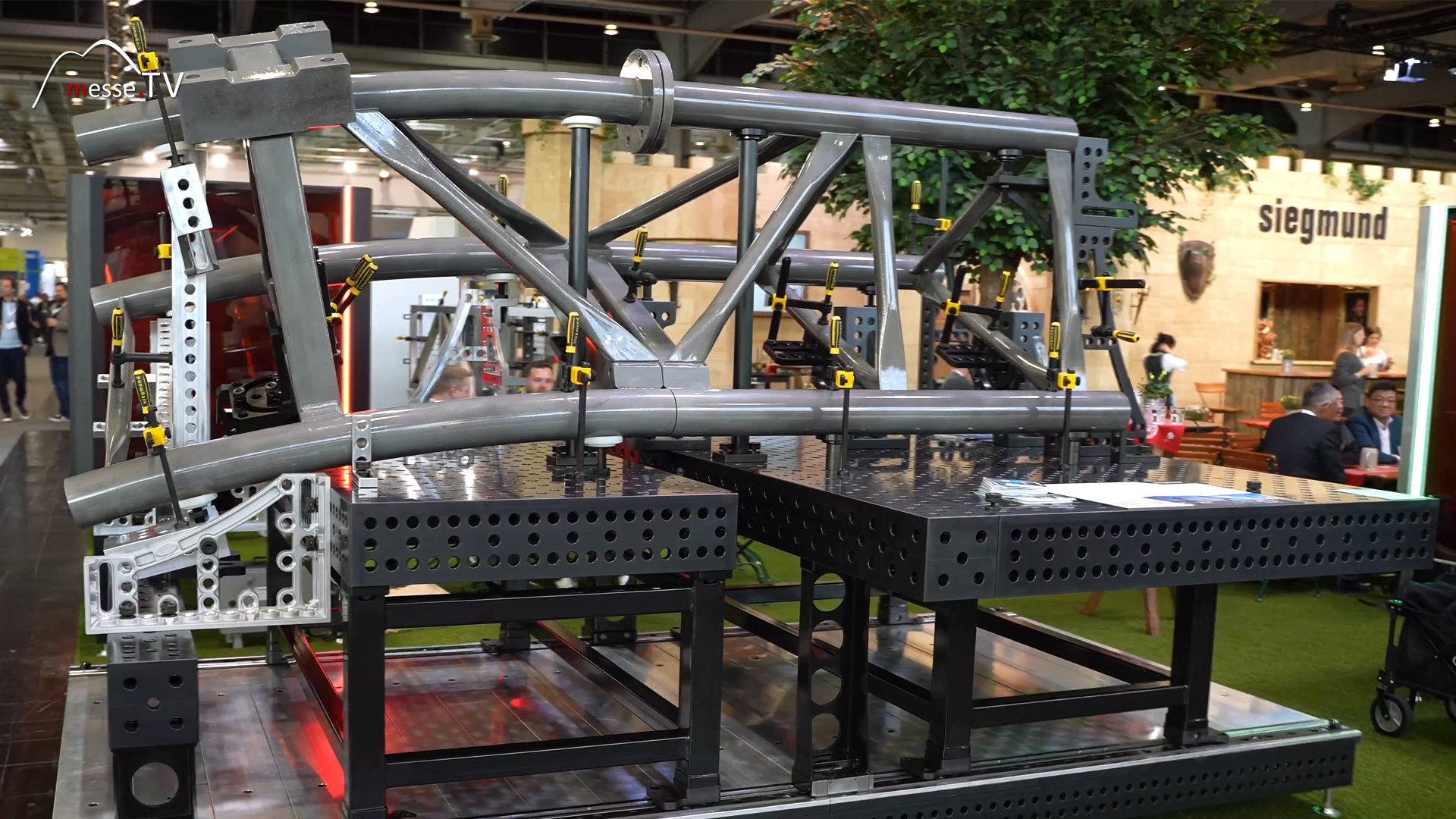

The sheet metal processing industry is undergoing profound change, characterized by new technologies and increasing demands for efficiency and sustainability. One key topic is the automation of manufacturing processes. From fully automated laser cutting machines to intelligent robots in forming technology - advancing digitalization is optimizing production processes and minimizing sources of error. Modern machines are seamlessly networked with ERP systems to enable precise production control. Artificial intelligence plays a key role here: self-learning algorithms recognize bottlenecks in production and automatically adapt processes to increase efficiency. Another trend that is shaping the industry is sustainability. More and more companies are turning to resource-saving technologies and materials. The use of recycled steel or new lightweight materials that require less energy to process is on the rise. CO₂-neutral production methods are also becoming increasingly important in order to reduce environmental impact. Machine manufacturers are developing energy-efficient systems that produce less waste and emissions. This combination of automation and sustainability is the key to the future of sheet metal processing and offers companies the opportunity to remain competitive while acting responsibly.

The EuroBLECH trade fair in Hanover

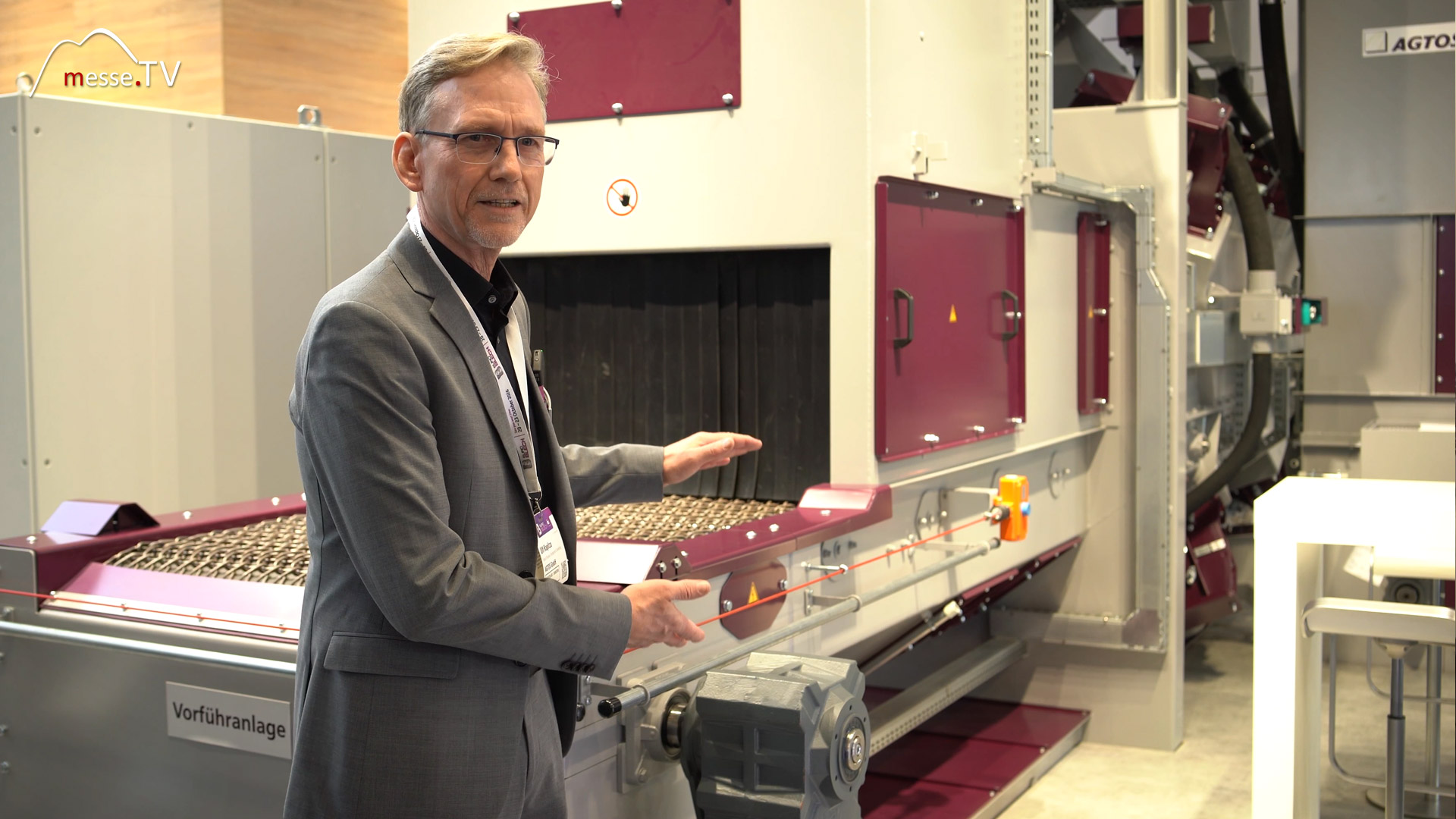

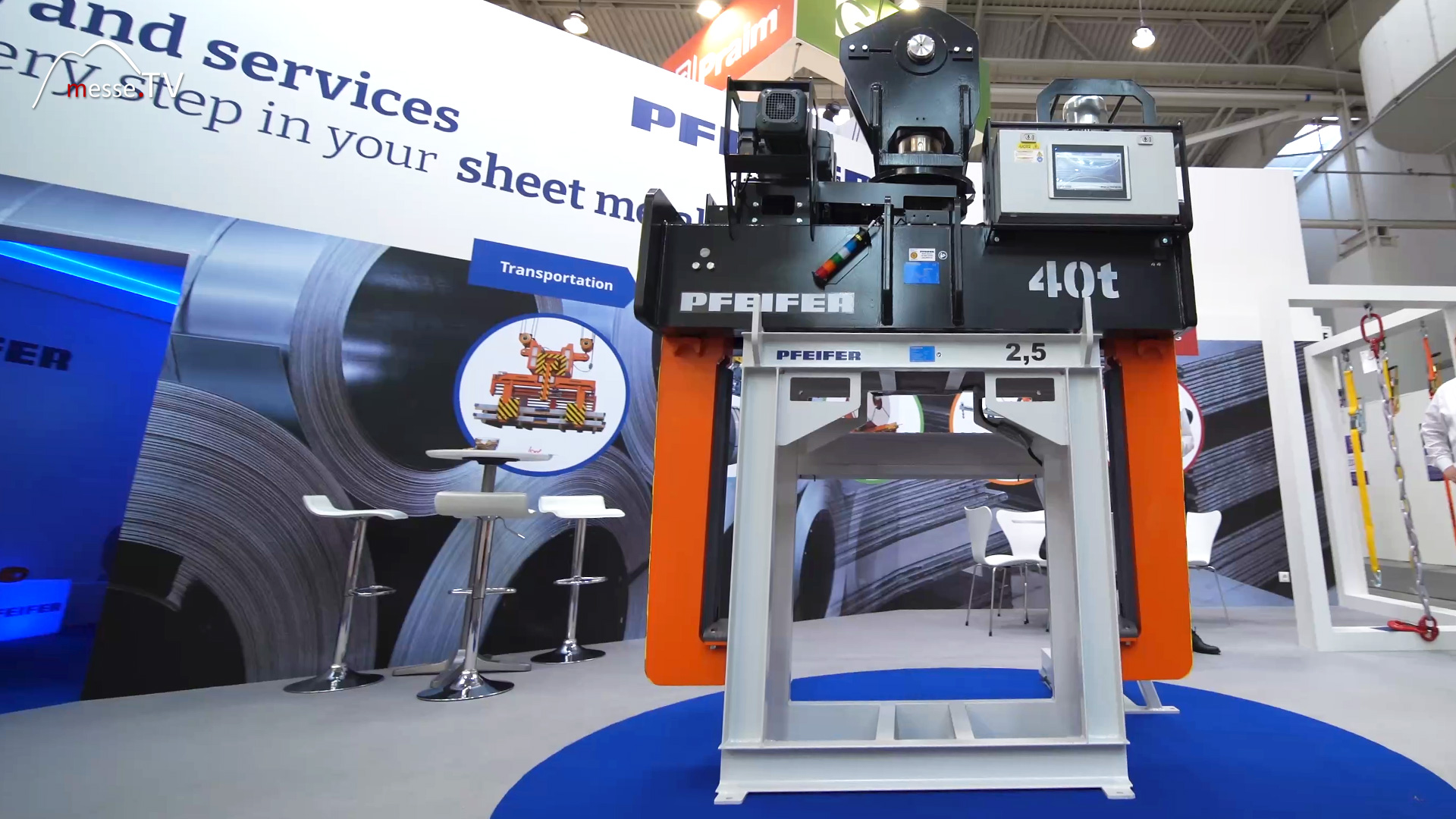

EuroBLECH is the world's leading trade fair for the sheet metal working industry and takes place every two years in Hanover. It is a central meeting point for professionals and companies involved in sheet metal working and provides a comprehensive platform for the exchange of knowledge, innovations and business contacts. The trade fair attracts exhibitors and visitors from all over the world and covers the entire spectrum of sheet metal working - from production and processing to the manufacture of end products. Leading companies and innovative start-ups present their latest machines, tools and technologies at EuroBLECH. The trade fair is known for its practical live demonstrations, where the latest developments and trends in sheet metal working are shown directly on site. The focus is on topics such as automation, digitalization, sustainability and increasing efficiency. A special highlight of EuroBLECH is the extensive supporting program, which includes specialist presentations, workshops and discussion panels. Here, participants can gain deeper insights into current topics in the industry, find out about best practices and benefit from the experience and know-how of leading experts. EuroBLECH in Hanover is a must-attend event for anyone working in the sheet metal working industry or interested in the latest innovations in this field. It offers an excellent opportunity to find out about the latest trends, make valuable business contacts and exchange ideas with experts from all over the world.