Oerlikon Surface Solutions AG, known under the brand name Oerlikon Balzers, offers innovative coatings to improve the performance and service life of precision tools and components. These coatings reduce friction and wear and are particularly in demand in metal and plastics processing. The company also offers specialized solutions for industries such as automotive, aerospace and medical technology. With a global network of coating centers, Oerlikon Balzers has a worldwide presence and is part of the Swiss Oerlikon Group.

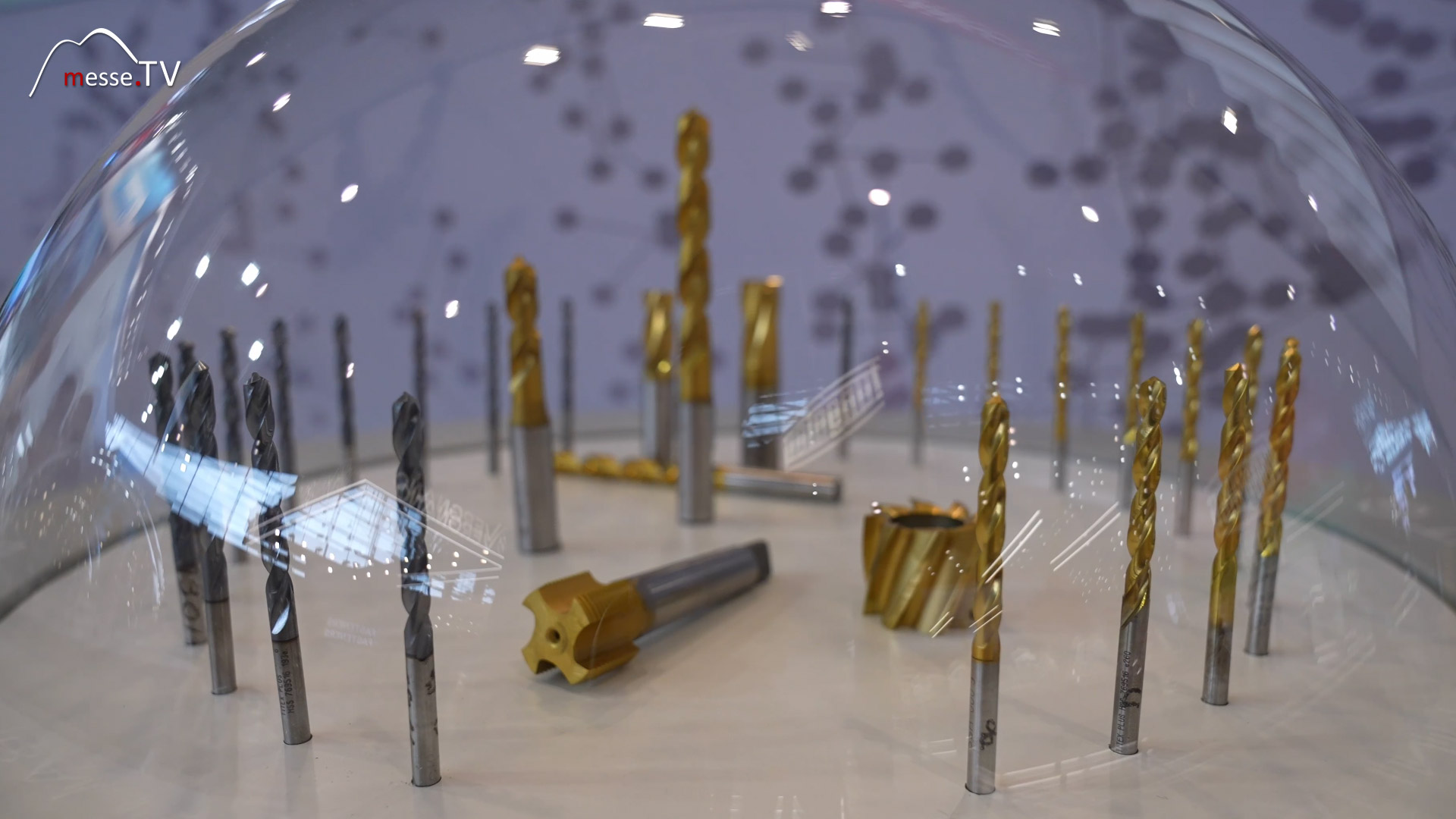

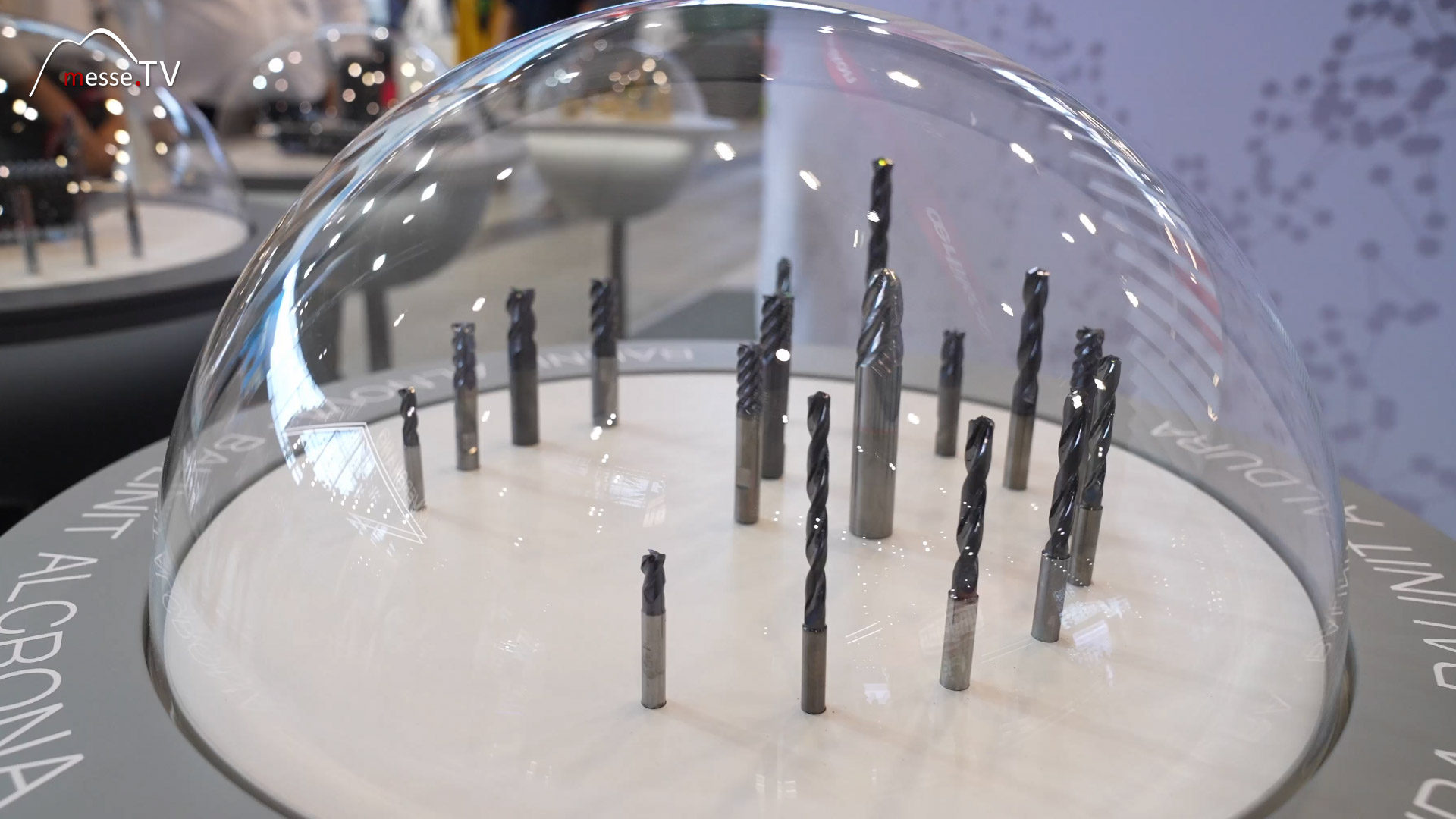

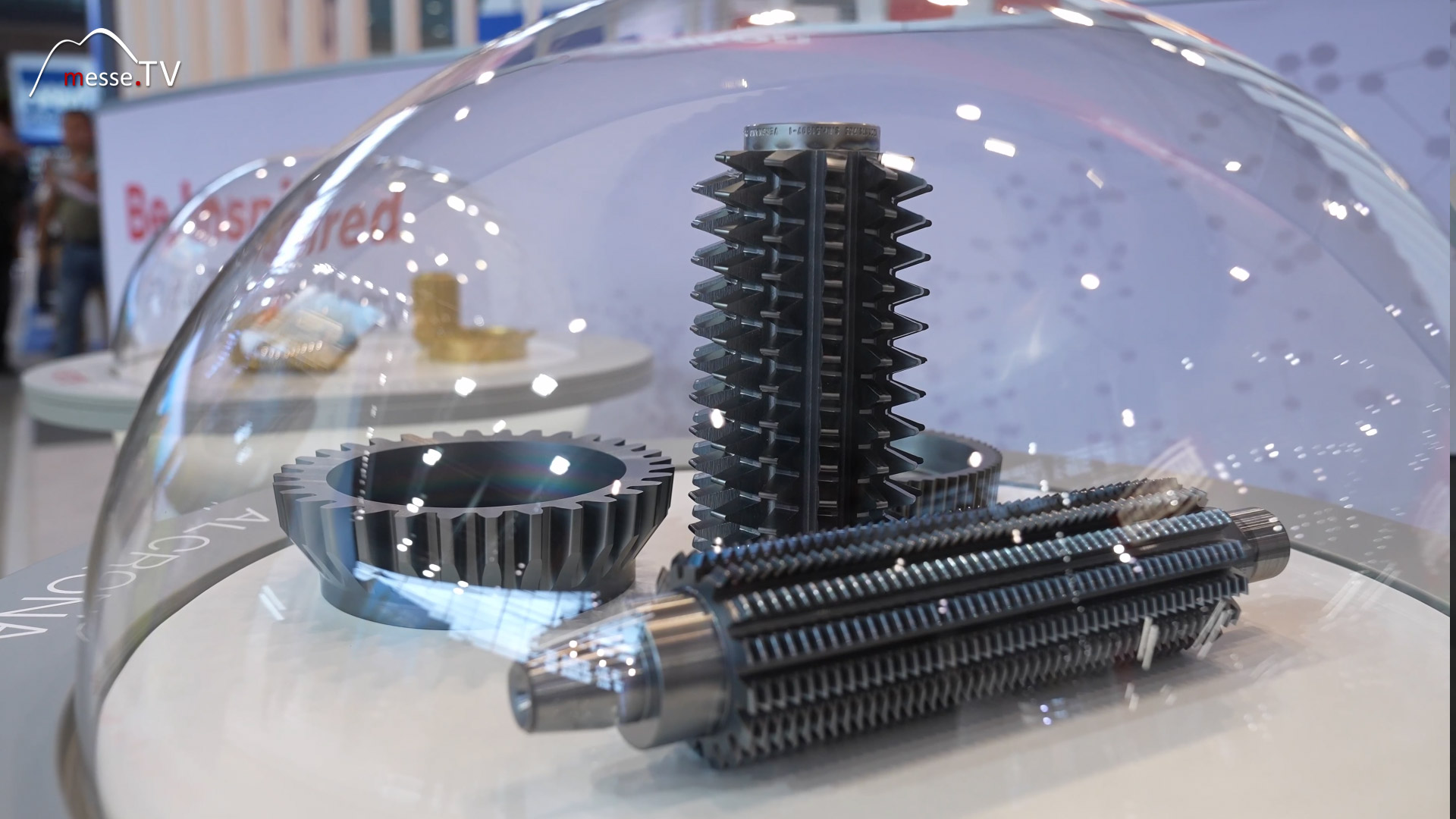

Since the 1970s, coating technology for the tool industry has undergone impressive development. Alcrona Evo represents a significant innovation in this area. This coating, which was launched in 2004, is now in its third evolutionary stage. It offers high oxidation resistance, hardness and hot hardness, making it a versatile solution for various applications such as drilling, milling and gear cutting. Alcrona Evo is described as a very high level broadband coating that is suitable for almost any tool application.

A central component of the business model is the recoating of tools. The sustainability achieved through the reuse of tools is particularly noteworthy. Tools such as hobbing cutters are recoated up to 20 times, which minimizes material consumption and conserves resources. The ecological process of PVD coating, in which no chemicals are used, makes this approach particularly environmentally friendly.

A special feature of the company is the production and operation of its own coating systems. These industrial systems make it possible to efficiently coat large quantities of tools such as drills and milling cutters. By improving the technologies on a daily basis, customers benefit from maximum efficiency and long-lasting products. The systems, in which millions are invested, are known for their durability and often remain in use for decades.