Hainbuch GmbH specializes in modern clamping solutions for metalworking and offers a wide range of chucks, mandrels and stationary clamping devices. The company attaches great importance to flexibility and efficiency, especially when it comes to reducing set-up times. In addition to standard products, Hainbuch develops tailor-made solutions for specific customer requirements and drives process optimization through automation and innovative technology. The clamping technology systems are used in various branches of industry.

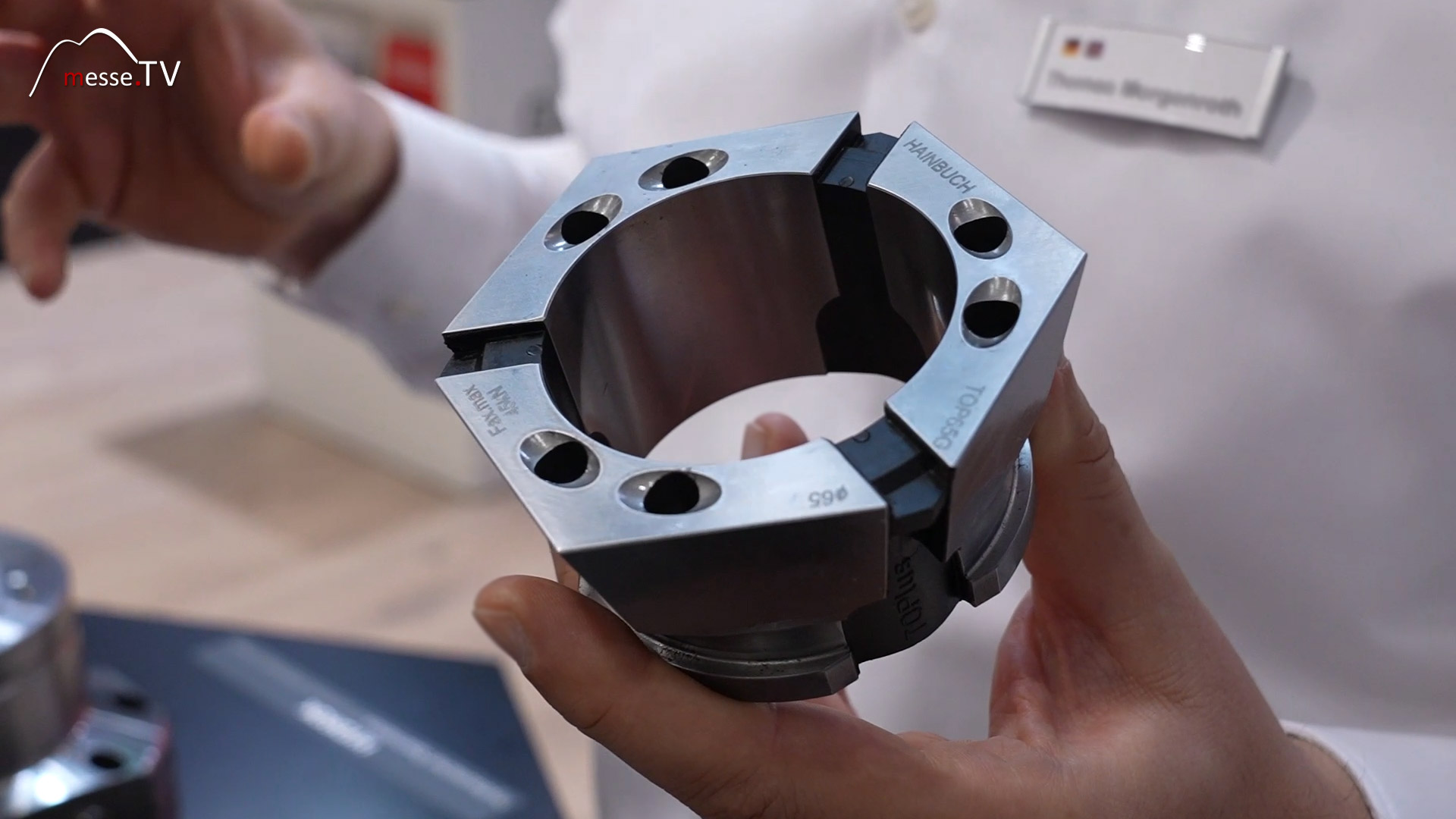

The Hainbuch clamping head offers maximum flexibility and easy handling. Thanks to the modular system, different clamping heads can be exchanged quickly and easily. The clamping head can be changed with a simple click, allowing quick adaptation to different workpieces and clamping diameters. The system is ideally suited for use in various industries such as the automotive industry, aerospace and medical technology.

In addition to classic chucks, Hainbuch also offers intelligent IQ chucks that measure the diameter of the components and monitor the clamping force thanks to integrated sensors. These chucks ensure precise and reliable clamping force control, enabling error-free and automated machining. These IQ chucks communicate directly with the machine and give the green light to start machining as soon as all parameters are set correctly.

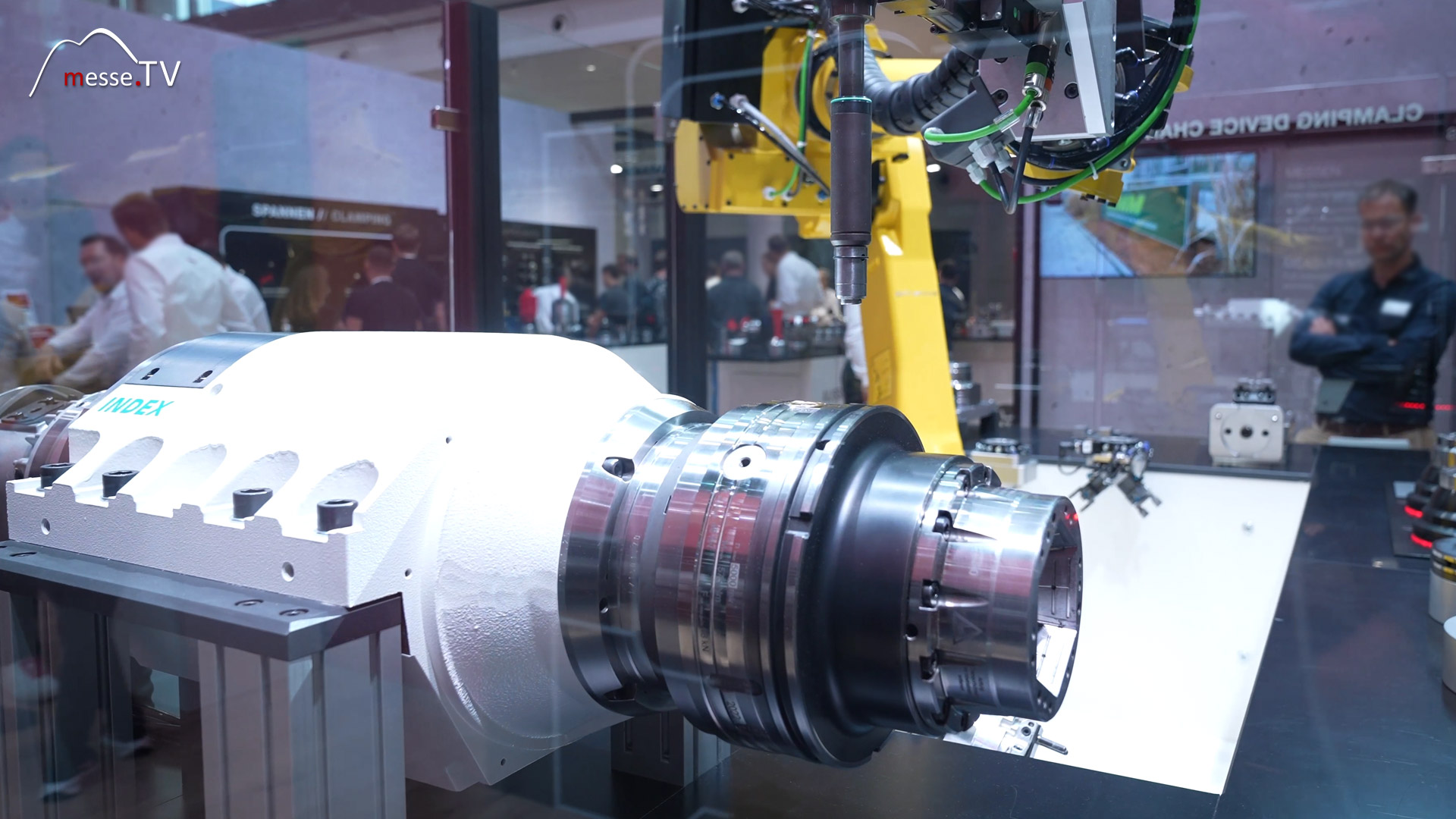

Hainbuch has developed a fully automatic set-up system in which robots change the clamping head and loosen and reattach the chuck to the spindle. This process enables an unmanned set-up time and ensures high precision in the milling area. Especially for recurring tasks and in series production, automation increases efficiency and reduces the need for skilled workers, which is a great advantage given the shortage of skilled workers in the industry.