MAS Tool Plate: Flexible tool plate system at the AMB 2024

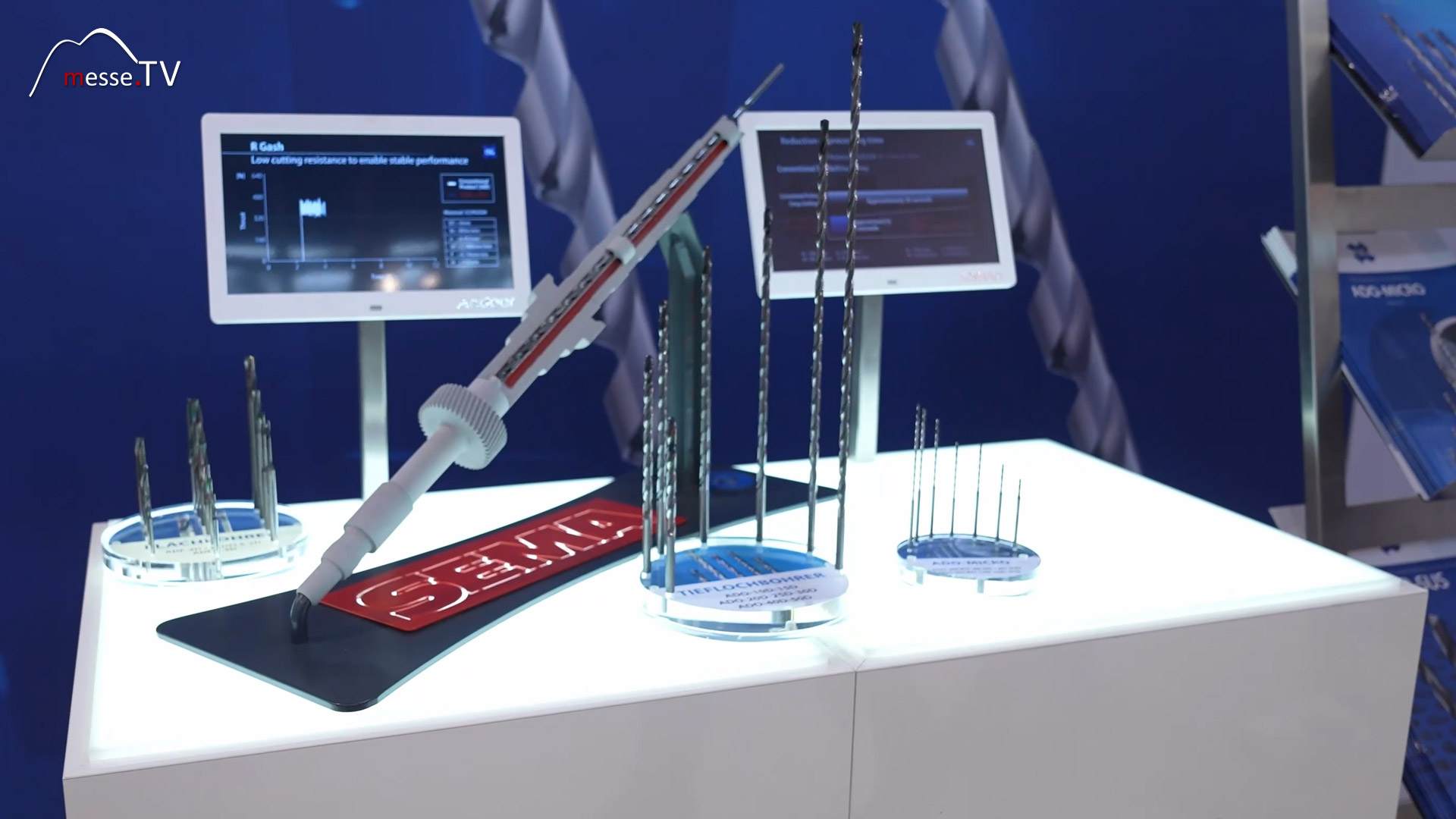

MAS offers a wide range of high-precision tools for metalworking, including turning, milling and drilling. In addition to standard products, the company also develops special tools that enable efficient and cost-effective machining. The aim is to sustainably increase productivity through innovative technology.

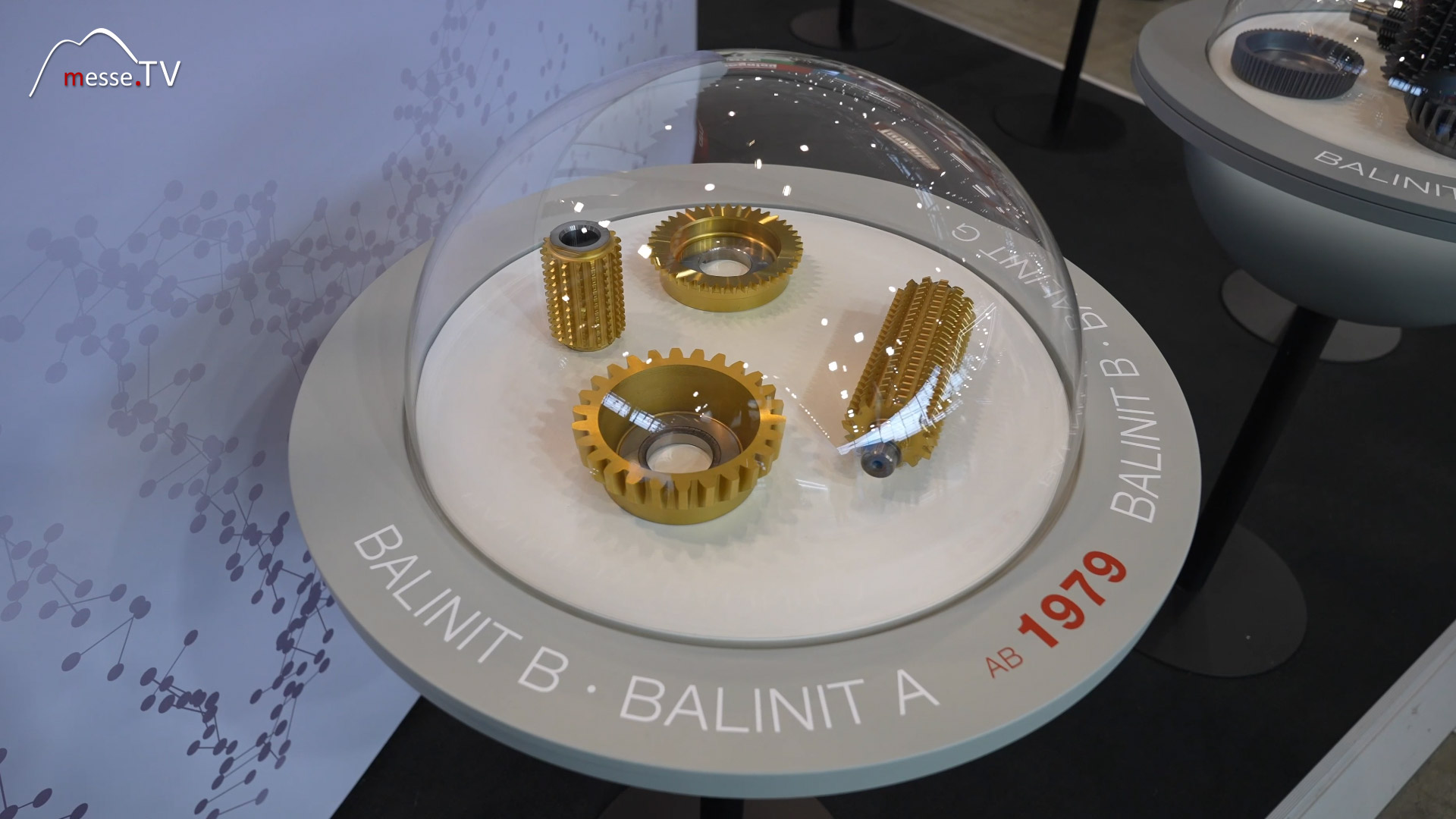

Tool specialists - 40 years of experience and innovative solutions

As tool specialists, the company has over 40 years of experience and focuses on the development of high-quality cutting edges. However, the aim is not only to develop the best cutting edge, but also to offer customers an optimum machining process. The focus is on flexibility and adaptability in order to always provide the best solutions for individual requirements.

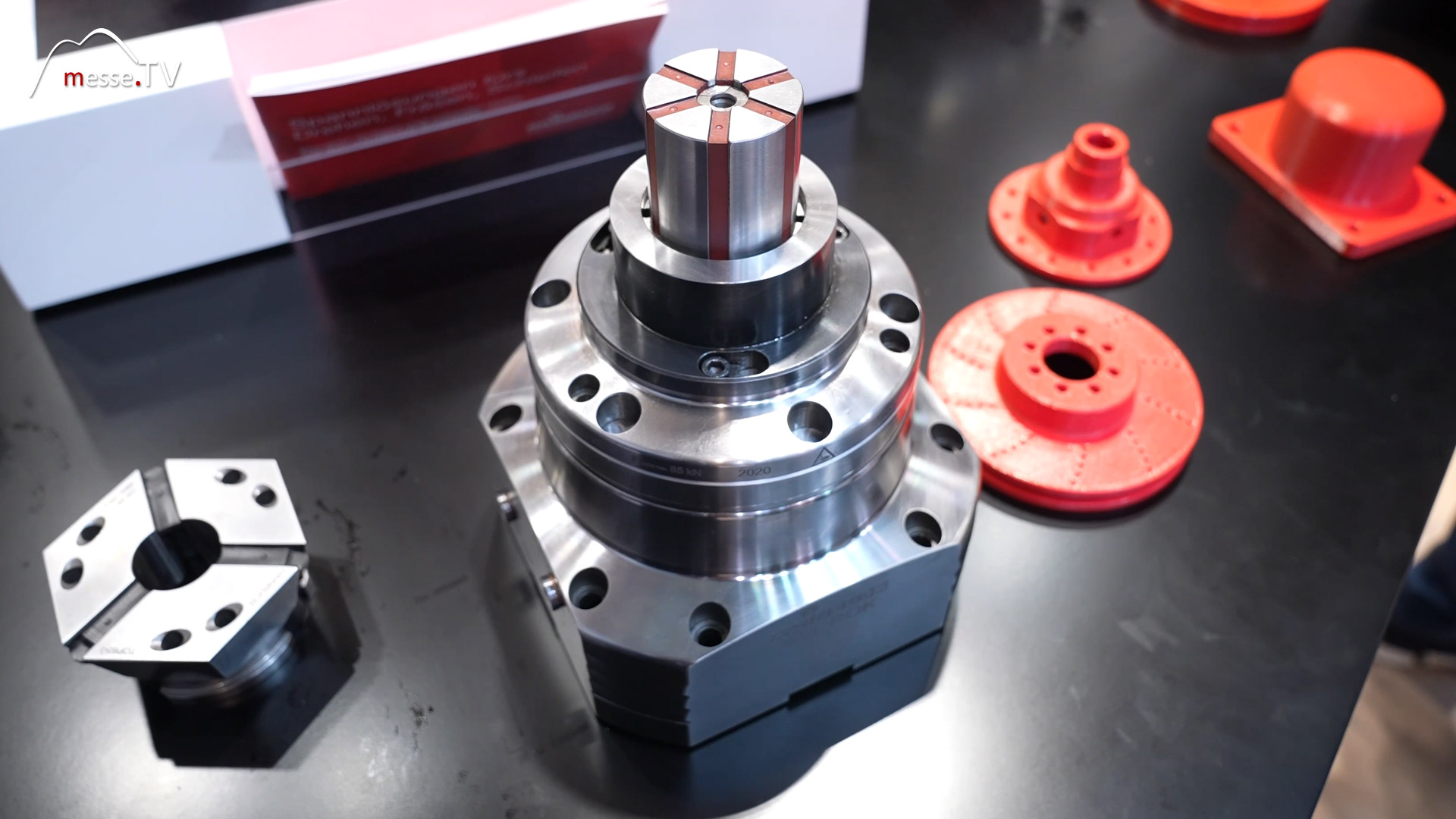

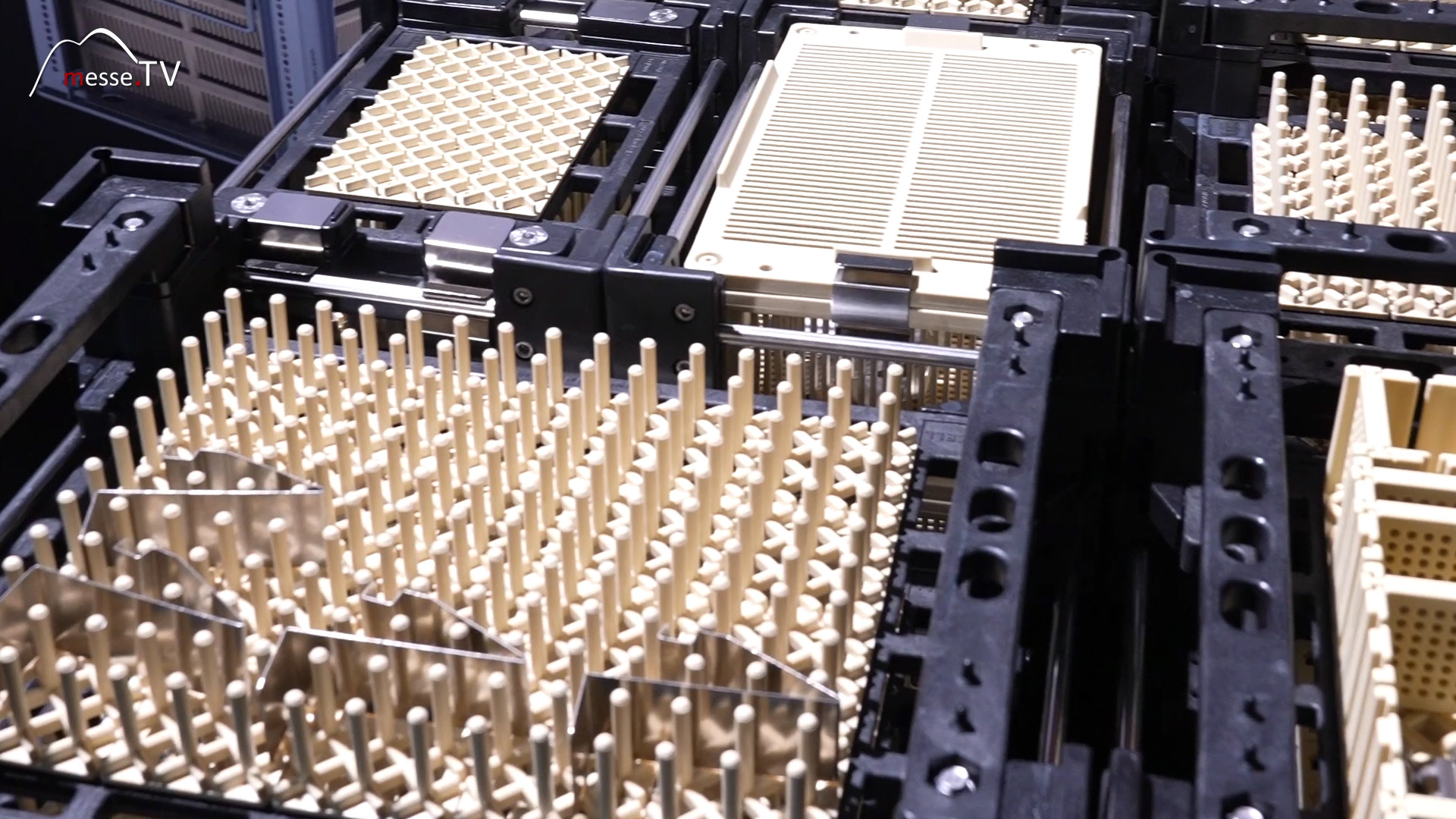

Tool Plate: Innovative solution for more efficient machining

The newly developed tool plate system, presented at AMB, is an extension of the existing gang plate system and offers numerous advantages for tool machining on sliding headstock lathes. One of the biggest innovations is the integrated coolant supply, which eliminates the tedious connection of hoses for each individual holder. All tools are cooled with just one connection, which saves time and makes the working environment cleaner and safer.

Reduced set-up times and increased machine running times

The Tool Plate and the associated PZ system not only significantly reduce set-up times, but also extend machine runtimes. Thanks to the quick-change system, tools can be prepared outside the machine and replaced in just a few seconds if necessary. This optimizes the production process, minimizes downtimes and increases efficiency. In times of a shortage of skilled workers, simple handling is a decisive advantage when it comes to increasing efficiency and productivity.