Wilhelm Blessing GmbH & Co. KG is a medium-sized company from Ostfildern that specializes in the development and manufacture of tailor-made clamping fixtures. Their products are used worldwide in the automotive industry, mechanical engineering and medical technology. They offer customized solutions for precise clamping devices and attach great importance to high quality "Made in Germany". In addition to production, the company offers comprehensive services such as maintenance and express repairs.

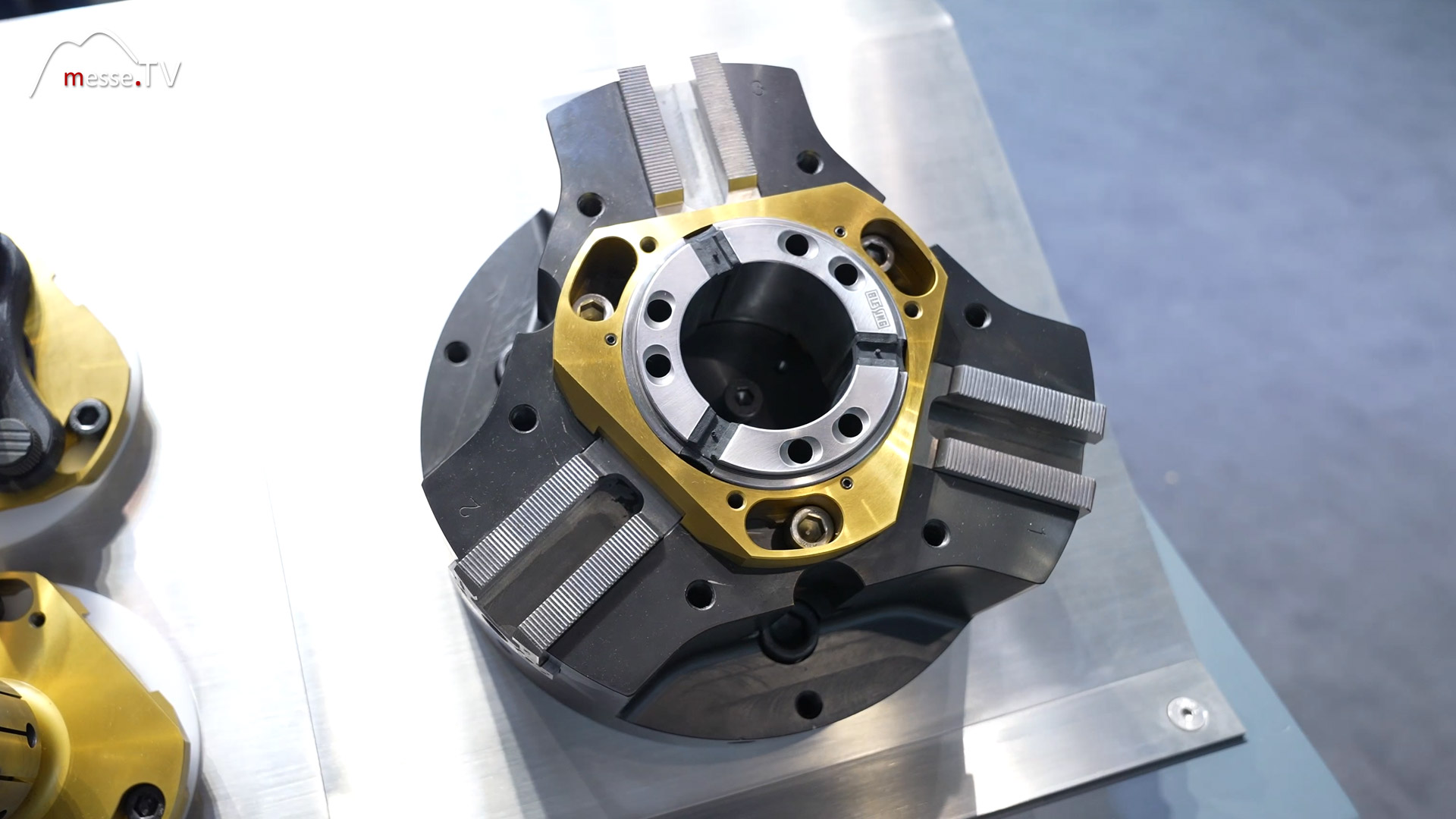

With Evoflex, an innovative clamping system has been developed that impresses with its modular design and short set-up times. Users benefit from high adaptability, easy handling and the possibility to implement individual solutions even for complex workpieces. The system is suitable for a wide range of applications – from classic turning and milling to special applications in the automotive industry or in smaller manufacturing companies.

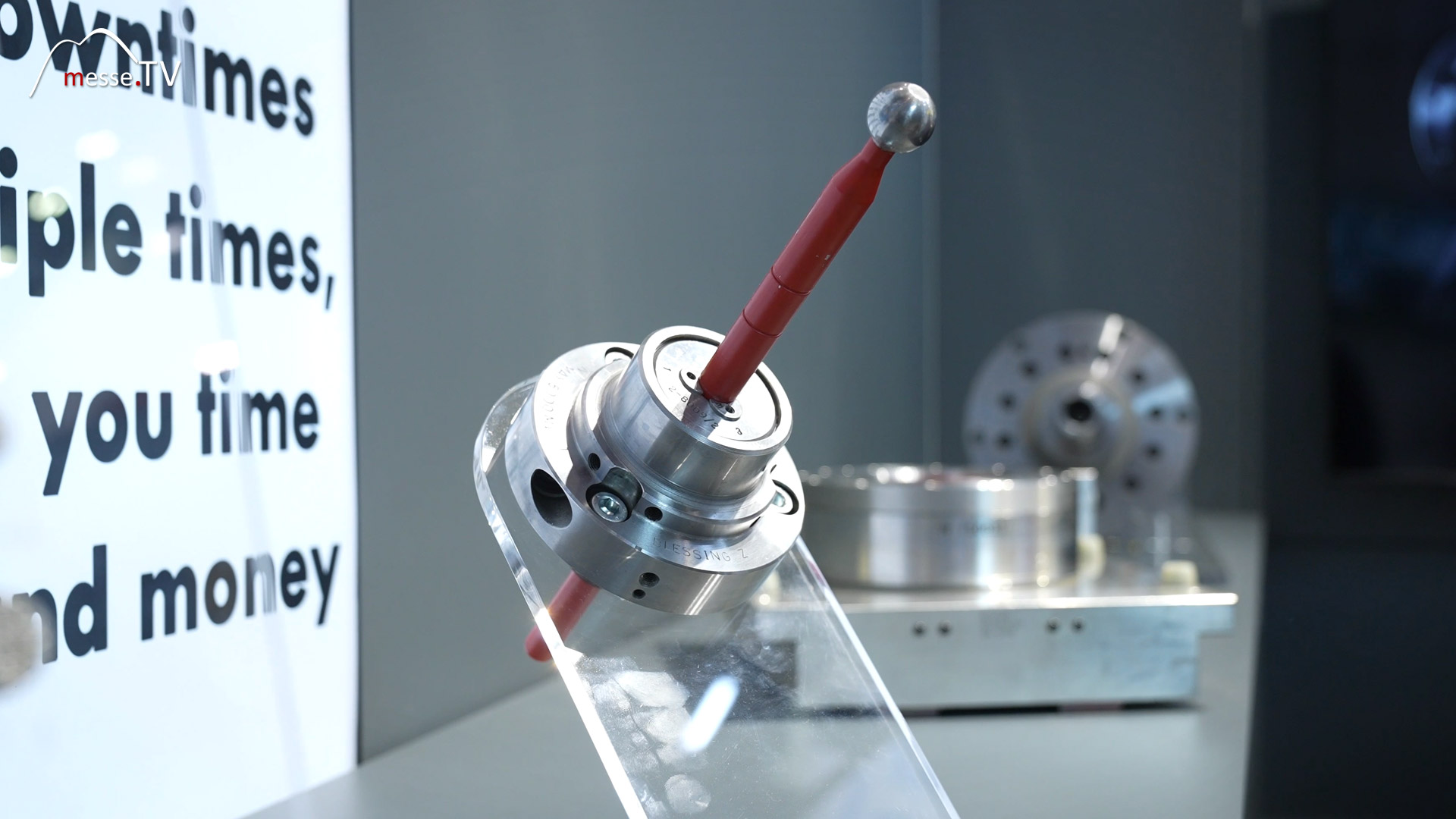

The special advantage of Evoflex lies in the well-thought-out quick-change system. The clamping head can be replaced in less than a minute – just three screws have to be loosened to switch from a classic three-jaw chuck to a collet or a mandrel. This reduces setup time to a minimum while ensuring a precise fit and reliable fixation of the workpiece. Various adaptations such as serrated jaws in metric or imperial versions, as well as quick-change systems, are already available. Special solutions are also developed in direct consultation with the customer, making Evoflex a future-proof clamping technology platform.

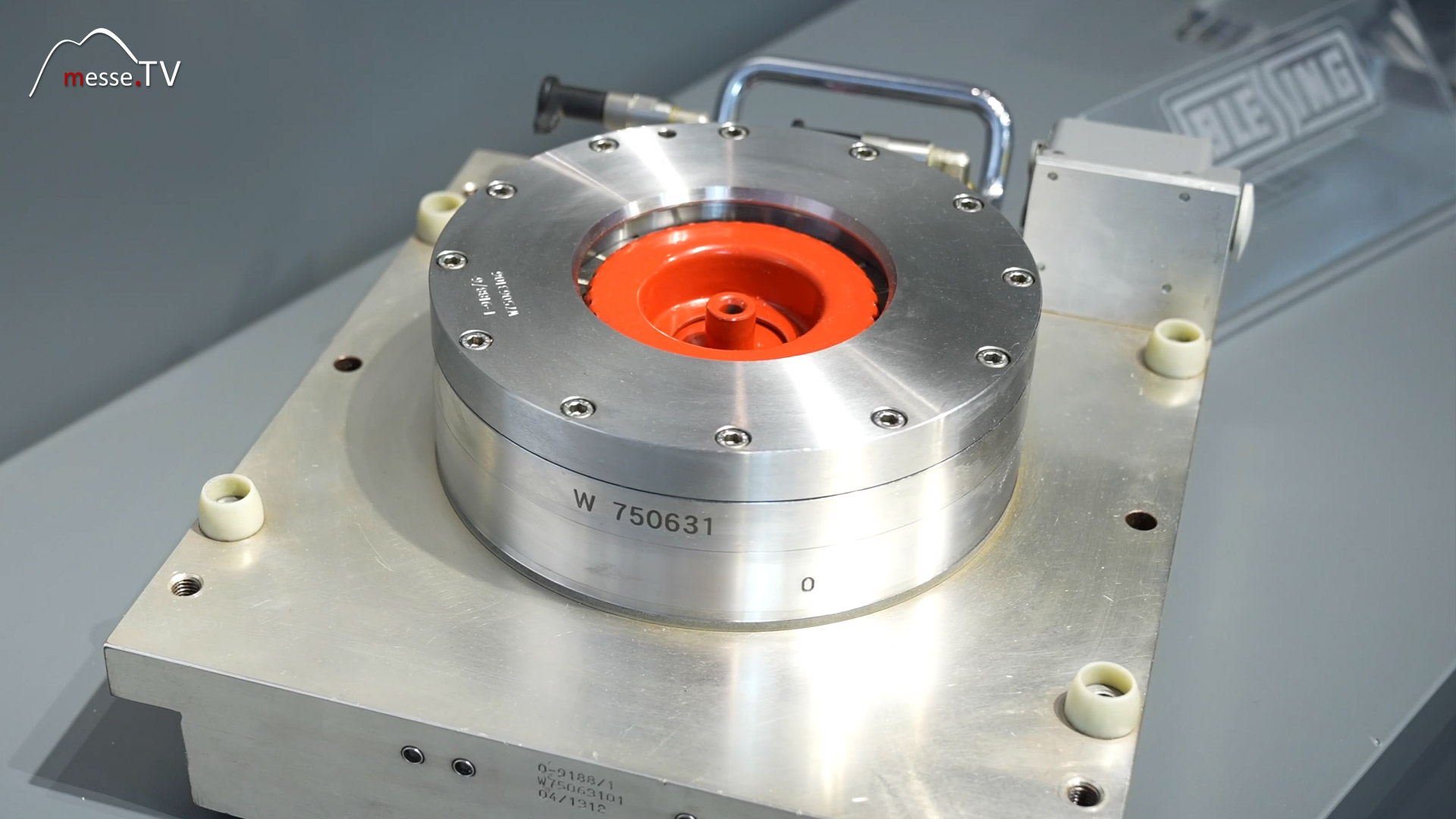

The compact design of the chuck offers a technical advantage. While other systems require additional adapters to use a collet, Evoflex has the collet integrated directly into the chuck. This not only saves on overall length, but also significantly reduces the overall height of the clamping device. This is a decisive factor, especially for machines with limited workspace. The base body remains permanently mounted on the machine – for the user, this means less downtime and high machine availability.

The development of individual clamping solutions often begins with a specific workpiece. If the customer does not have a suitable clamping device, a specific solution can be developed on the basis of a drawing or a 3D model. This approach not only ensures a high level of accuracy, but also creates a close relationship between manufacturer and user. Each project is considered a one-off – series production is the exception. This is how we create clamping devices that are precisely tailored to the respective application and function reliably even with complex geometries.

The fact that the Evoflex system is not only convincing in theory is demonstrated by its numerous uses on machines from well-known manufacturers such as DMG. The chucks have been tested extensively for function, durability, and ease of use – with consistently positive feedback. The design is geared towards a long service life, which makes it particularly interesting for continuous industrial use. At the same time, the system remains open to expansions: new requirements from practical applications are continuously incorporated into the further development, so that Evoflex not only represents a current solution, but also a sustainable investment in manufacturing technology.