MAS develops and manufactures high-quality tools and solutions for machining technology. Customized innovations maximize precision, efficiency and flexibility in metalworking. Customers benefit from comprehensive process optimization and individual tool solutions that are specially tailored to their requirements.

MAS stands for "people, standards, synergies" and pursues the approach of developing optimal solutions together with customers and employees. As a tool manufacturer from Leonberg, MAS specializes in cutting edges and tools, both in the standard and special areas. With over 40 years of experience, the company offers its customers tailor-made solutions for a wide range of machining technology requirements.

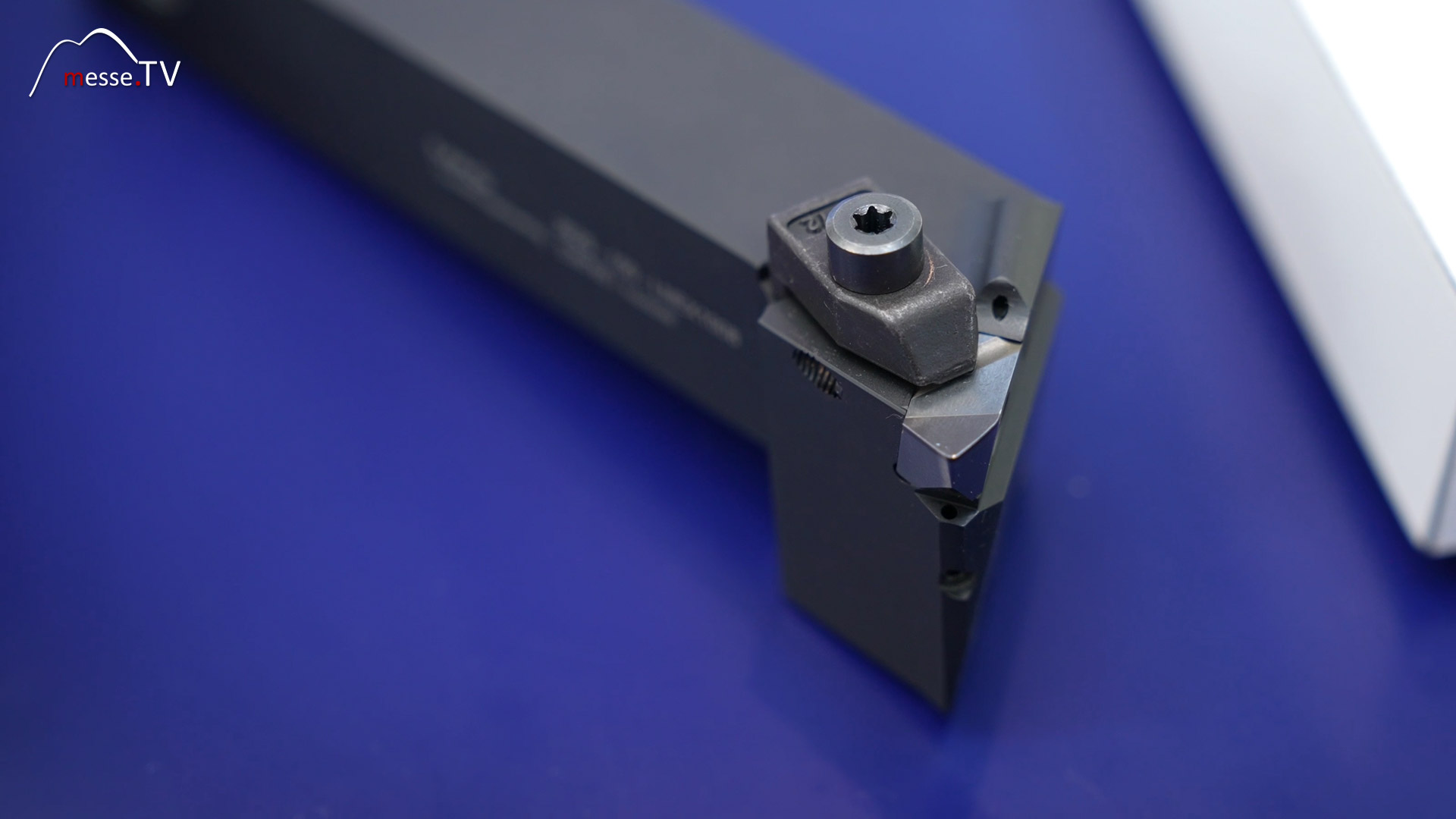

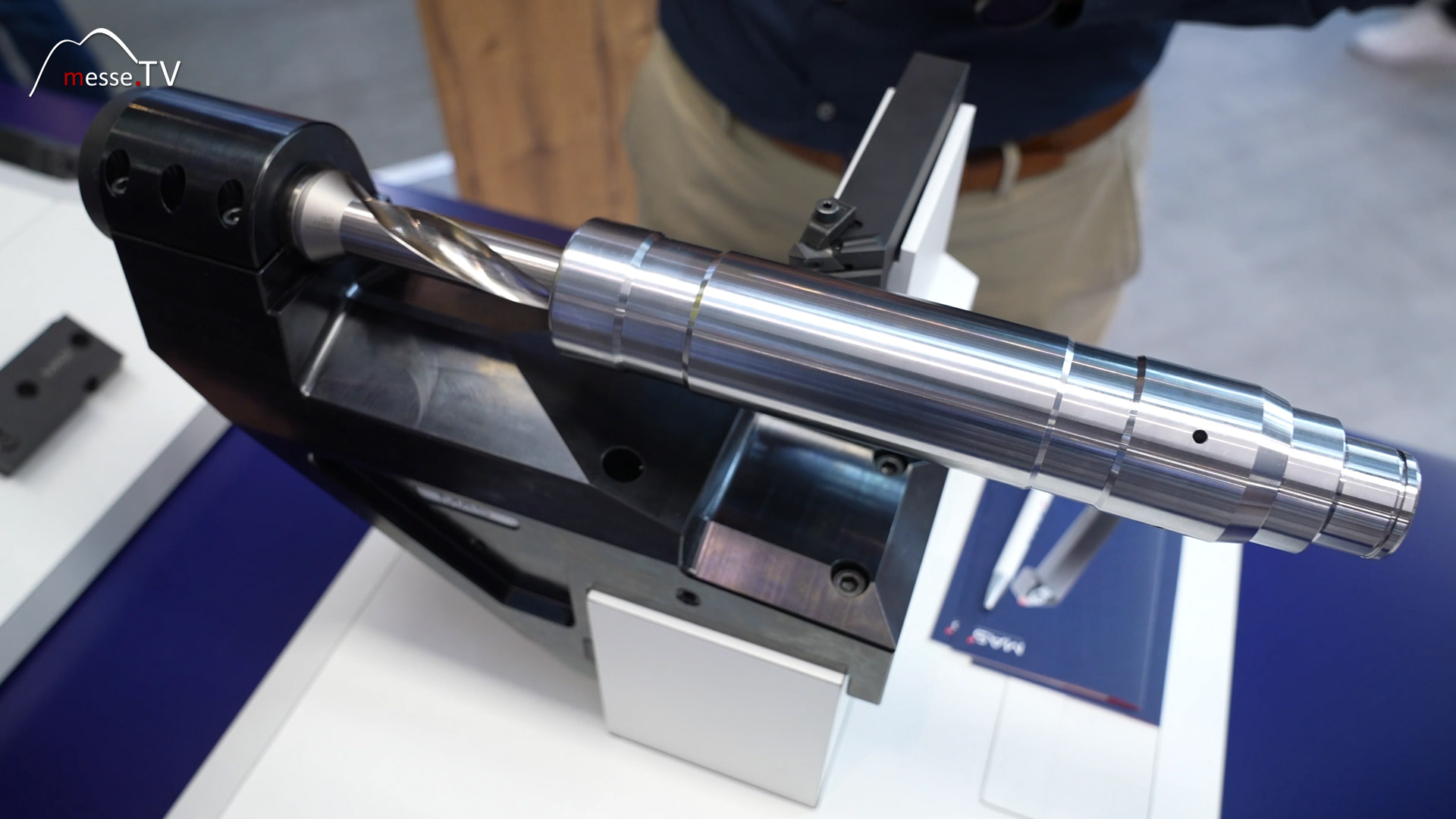

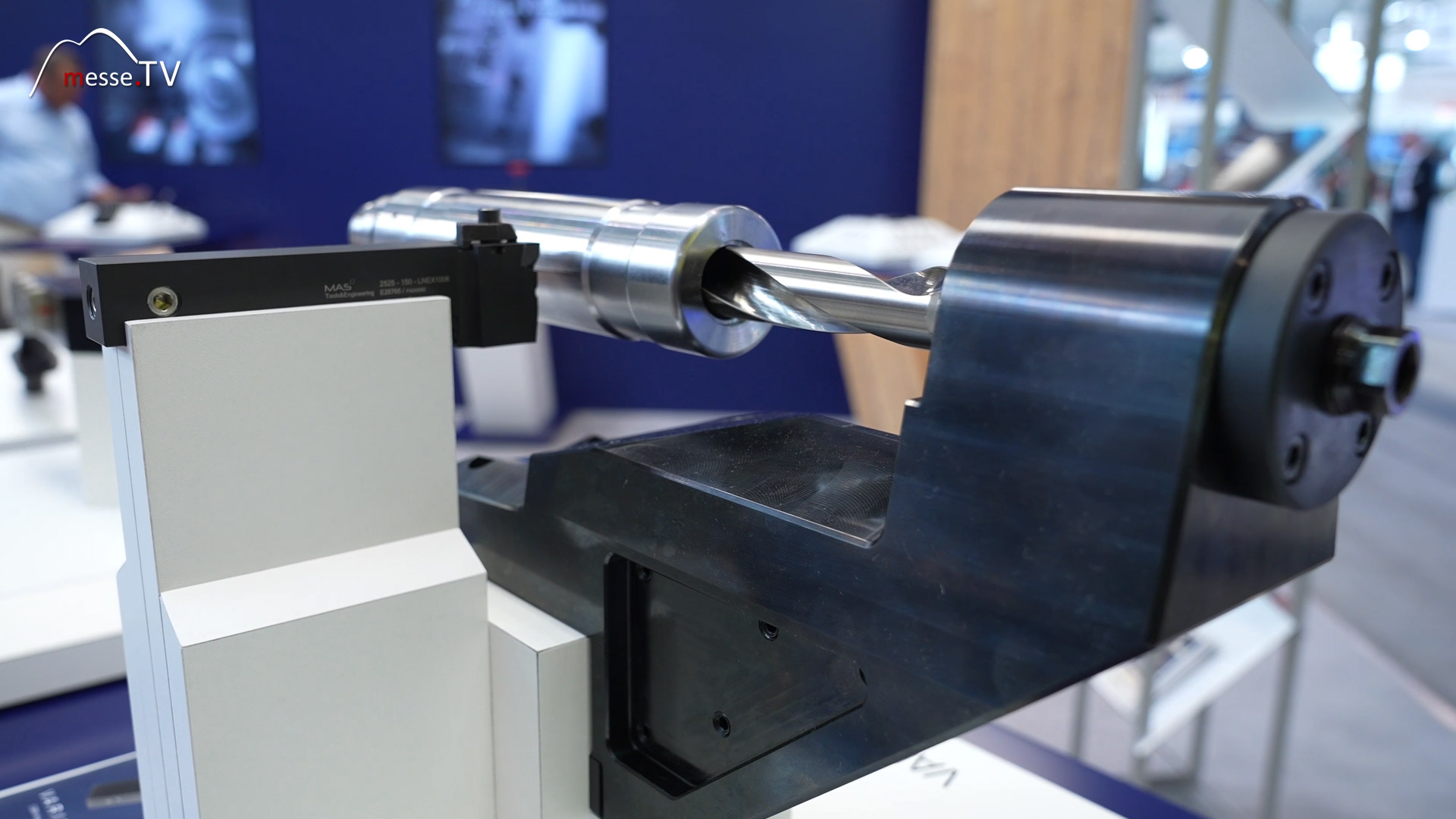

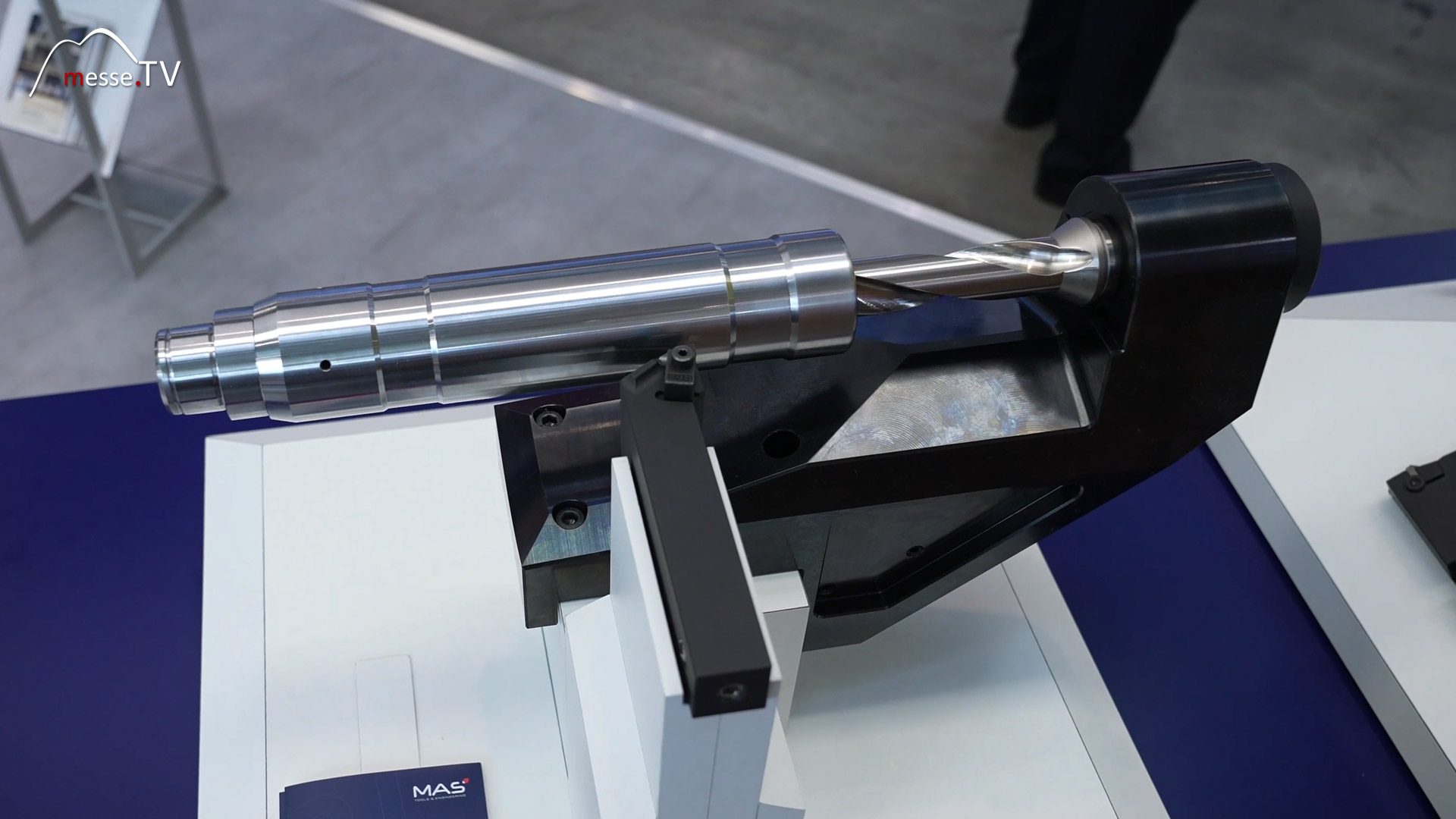

The latest product from MAS, the Vario Turn, is a high-feed turning system that is suitable for hard and soft machining. The special geometry of the insert seat ensures optimum stability and process reliability. With the Vario Turn, feed rates of up to 1.5 millimetres per revolution can be achieved, which is particularly advantageous when machining hard materials such as 60 HRC. The tool is versatile and can be used for both pulling and pushing cuts, making it extremely flexible.

One of the outstanding features of the Vario Turn system is the patented PSI internal cooling, which directs the coolant jet specifically into the effective zone. This is particularly important at high feed rates in order to break stable chips and maximize productivity. With double cooling and secure clamping of the indexable insert, the Vario Turn not only offers high stability, but also the ability to perform both roughing and finishing operations in a single pass - with minimal set-up times.