Gressel: Efficient clamping technology solutions presented at AMB 2024

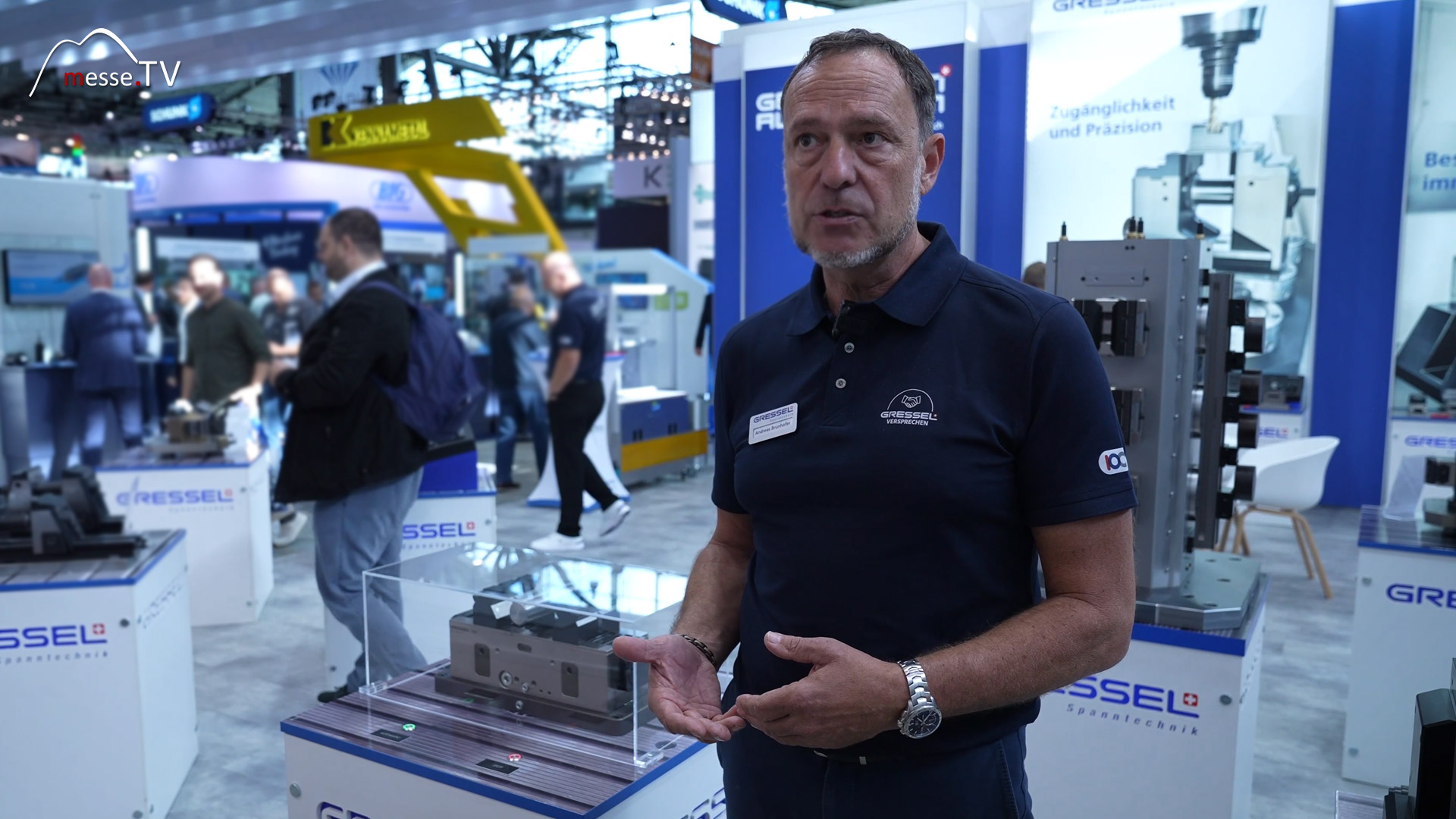

GRESSEL AG is a leading company in the field of clamping technology and offers solutions for metalworking and CNC manufacturing. With an extensive range of clamping systems, including zero-point clamping systems and 5-axis clamps, GRESSEL supports the optimization of production processes. Their products improve efficiency and reduce workpiece costs, maximizing machine uptime. In addition to standard products, the company also offers customized clamping solutions for individual production requirements.

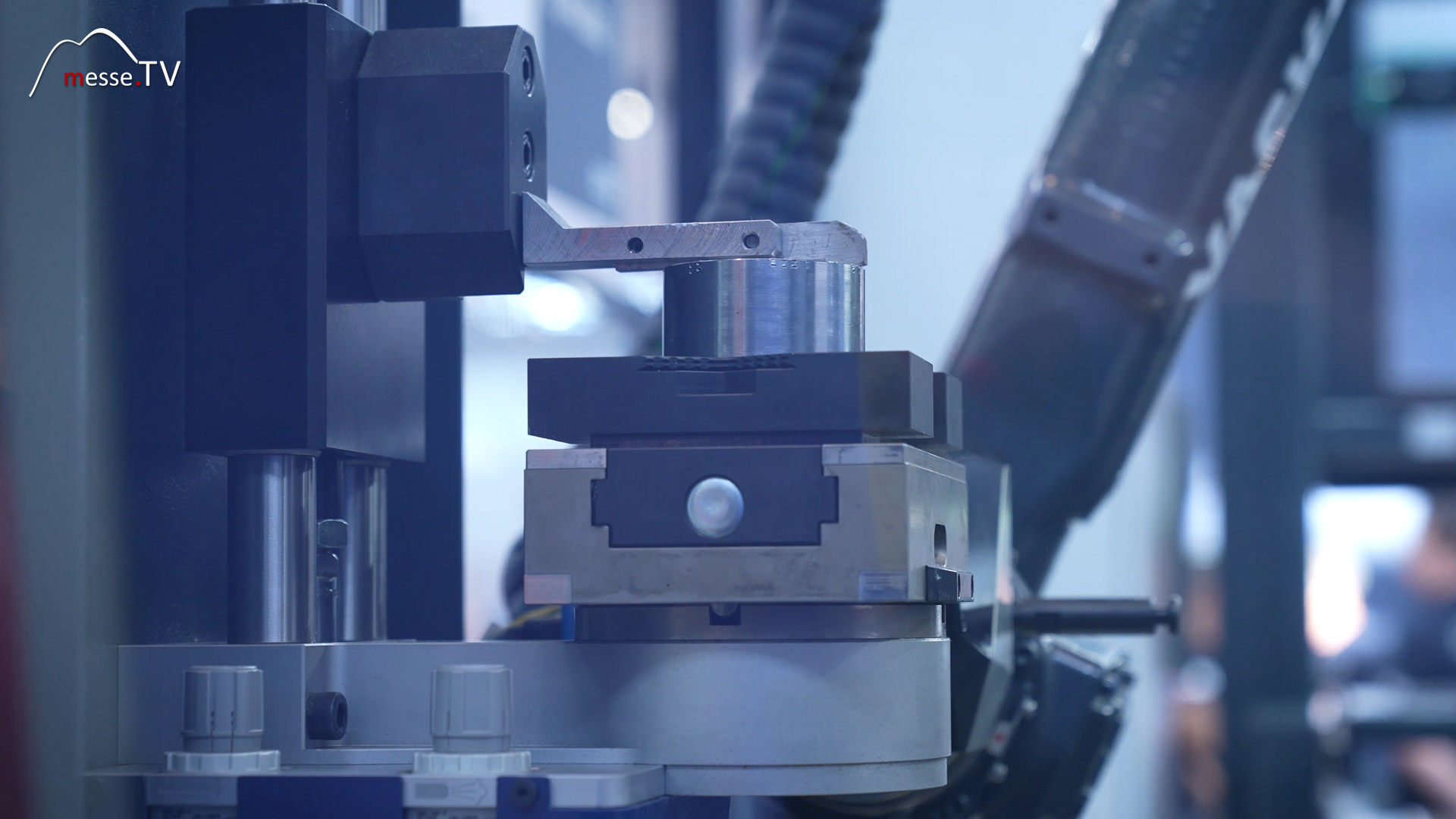

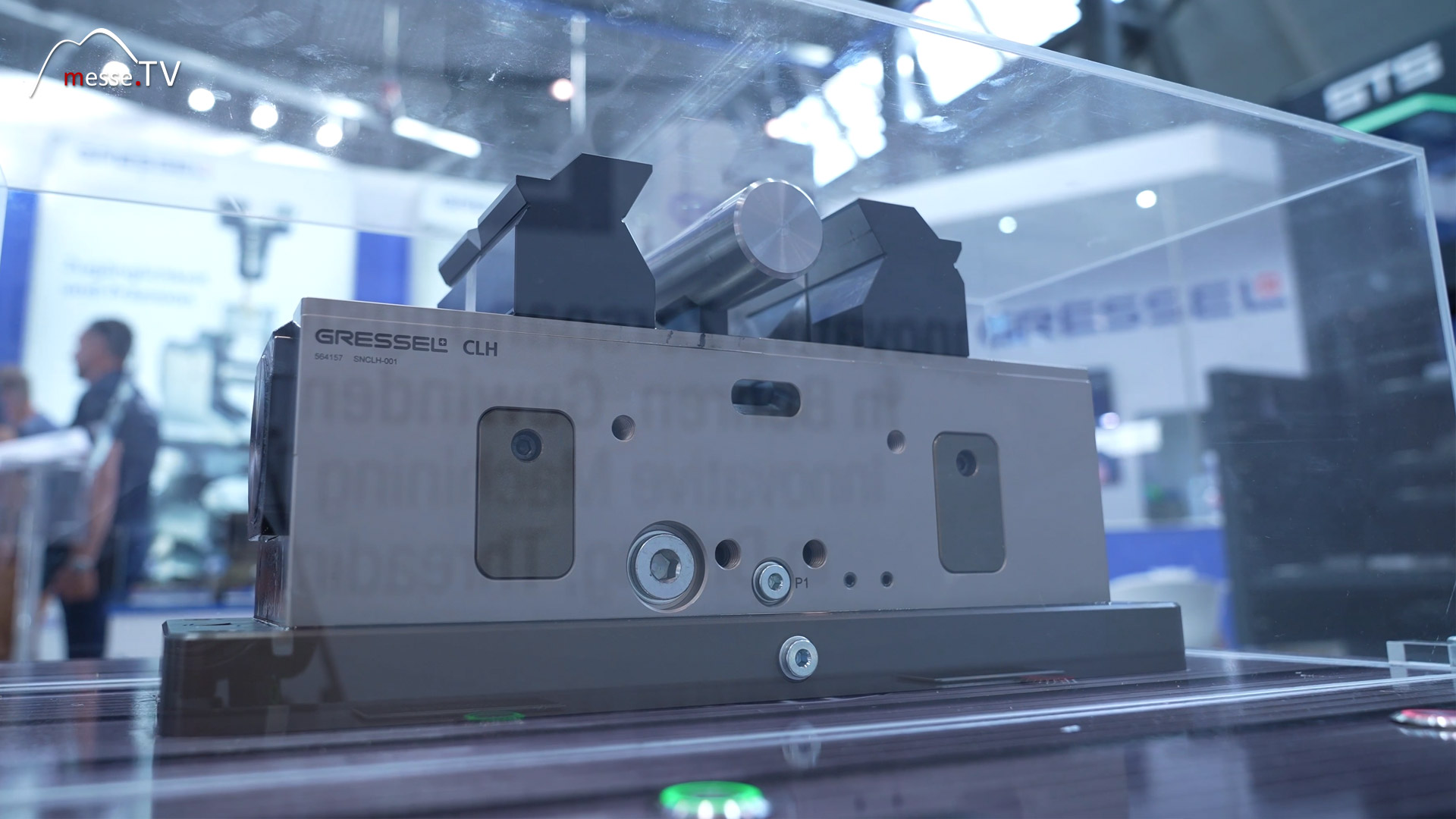

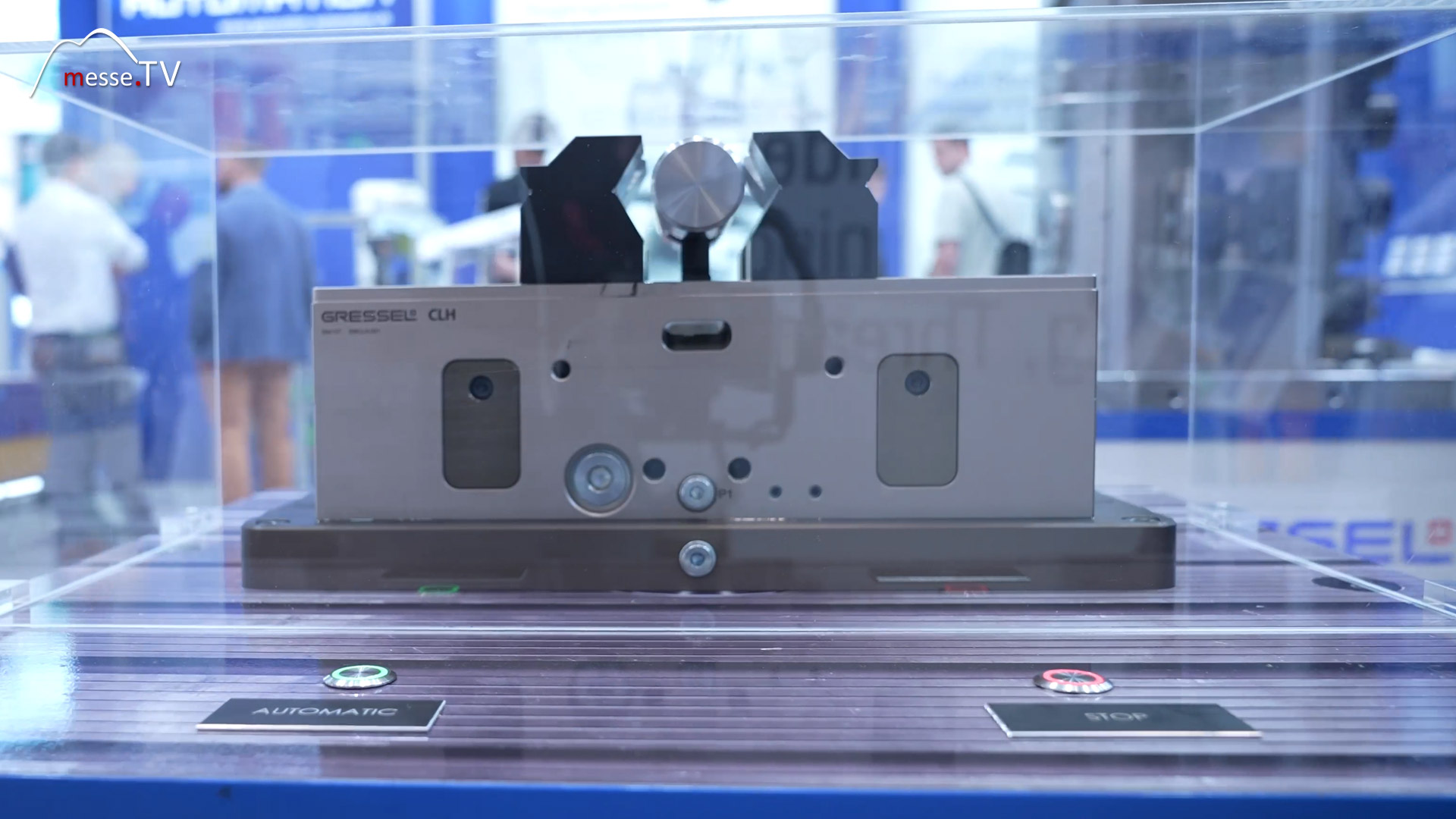

New large lifting clamp: Hydraulic innovation for metalworking

With a pressure of 230 bar and a clamping force of 80 kilonewtons, the new large hydraulic lifting clamp offers impressive performance. With a stroke of 110 millimeters, it enables a wide range of components to be clamped. This clamp offers decisive advantages, particularly in metalworking and machining, whether in the automotive industry or for series manufacturers. The larger clamping width and improved accessibility for 5-axis machines ensure optimum flexibility and efficiency.

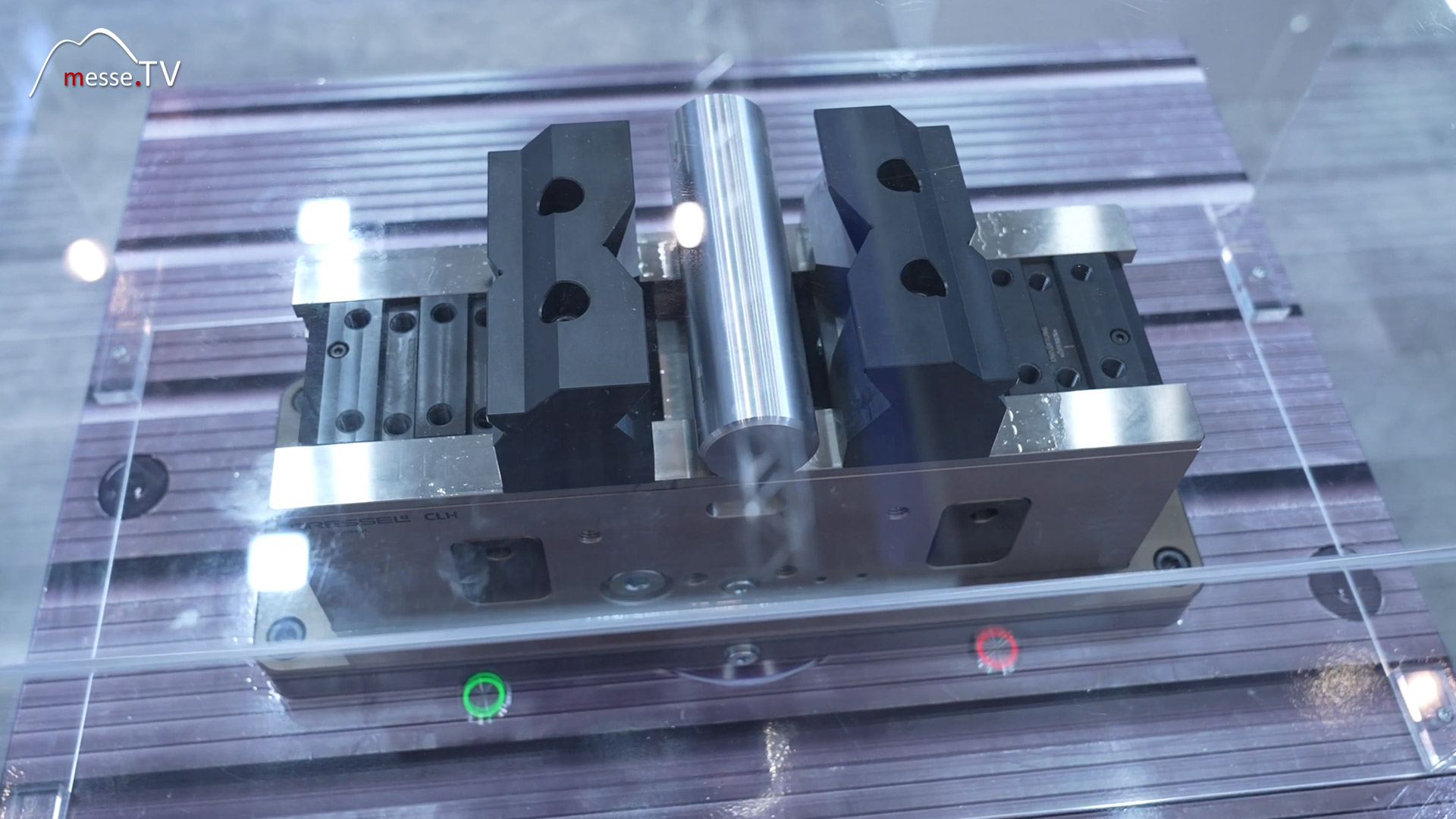

Electric clamps: Maximum precision and flexibility

The new electric clamp is another innovation that scores points with a clamping force of 80 kilonewtons and a stroke of 120 millimetres. The ability to change the spindle at any time means that the clamp remains versatile. The fully electric control ensures precise clamping force and movements, ideal for use in automated processes.

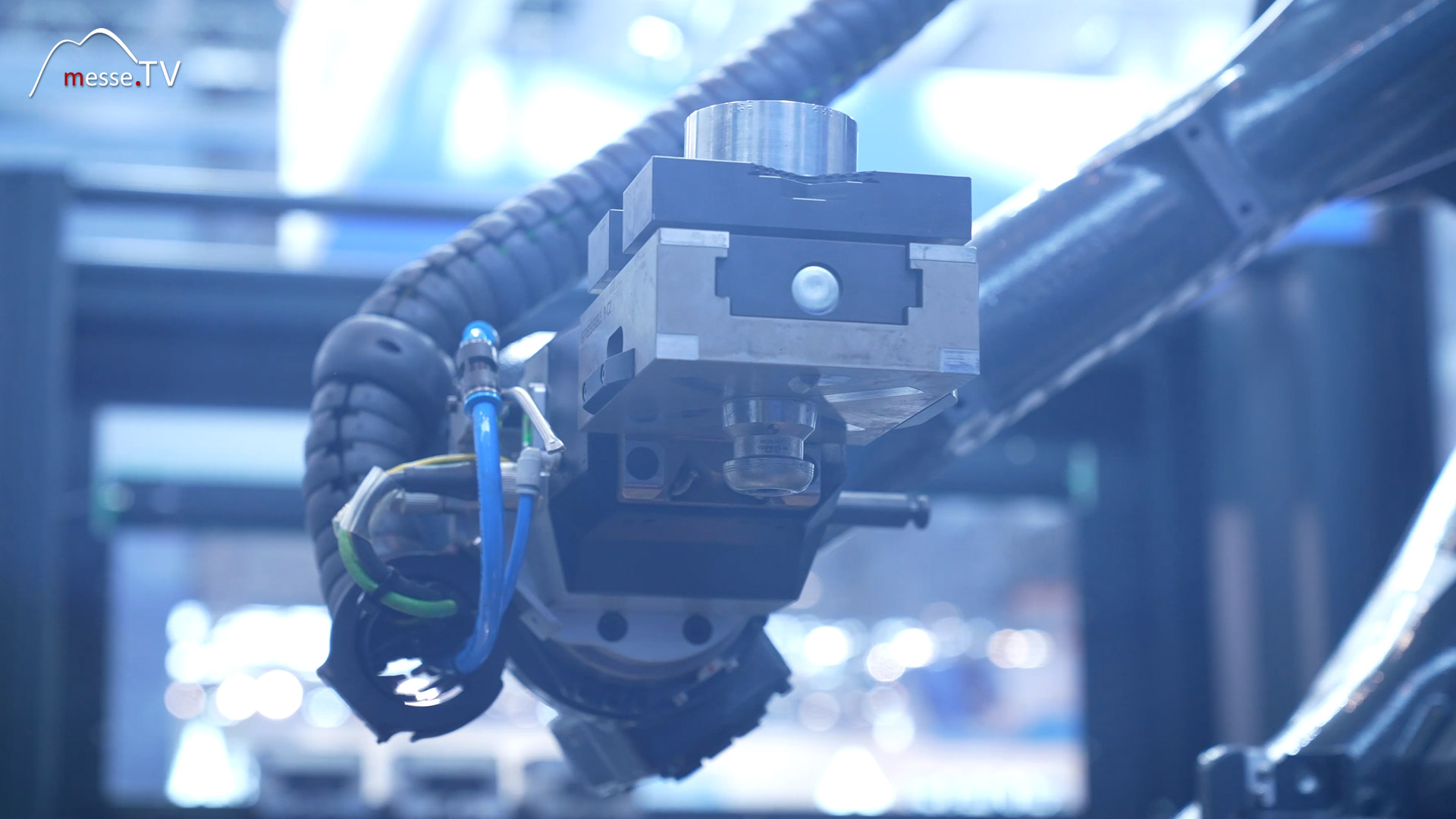

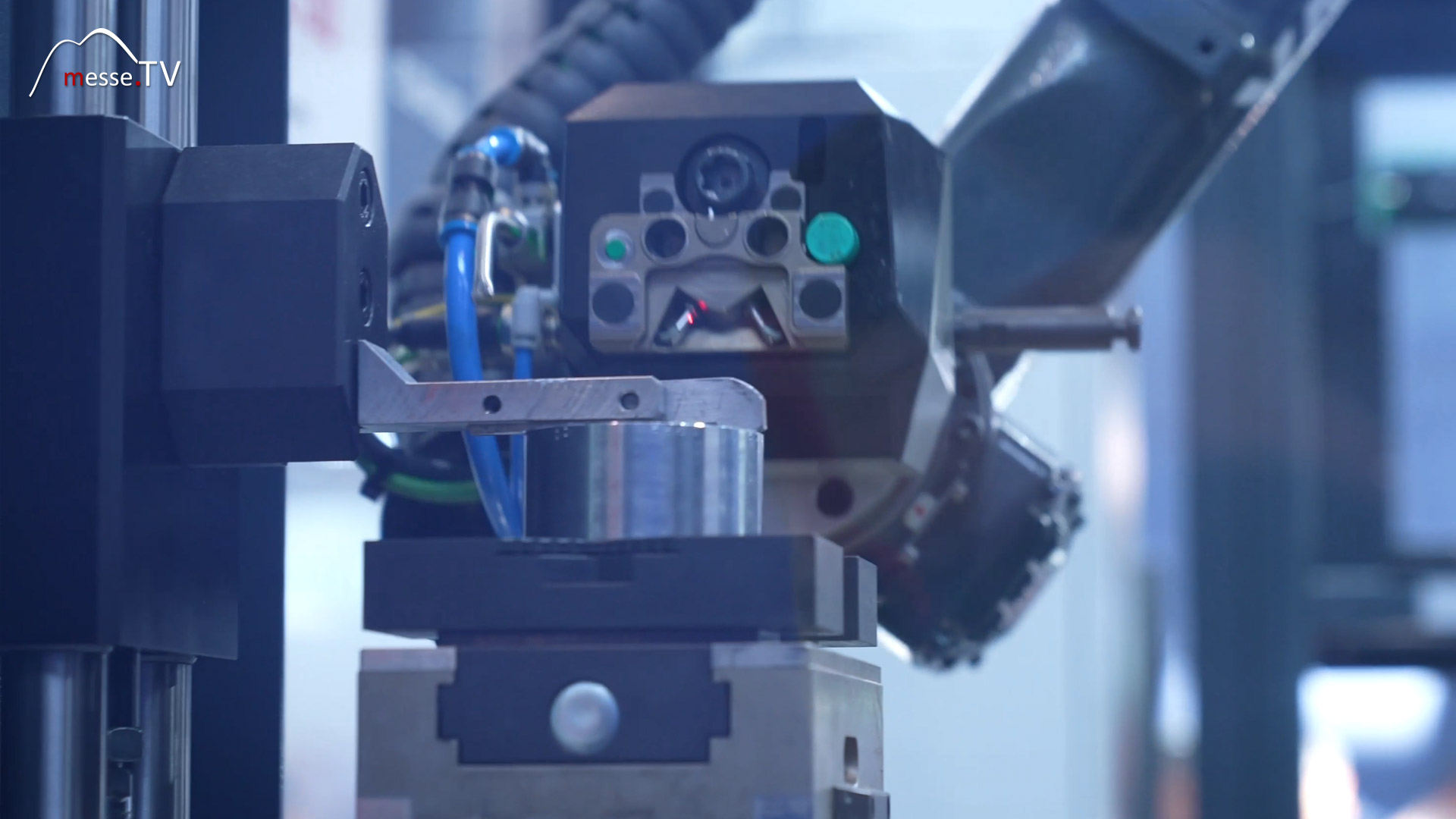

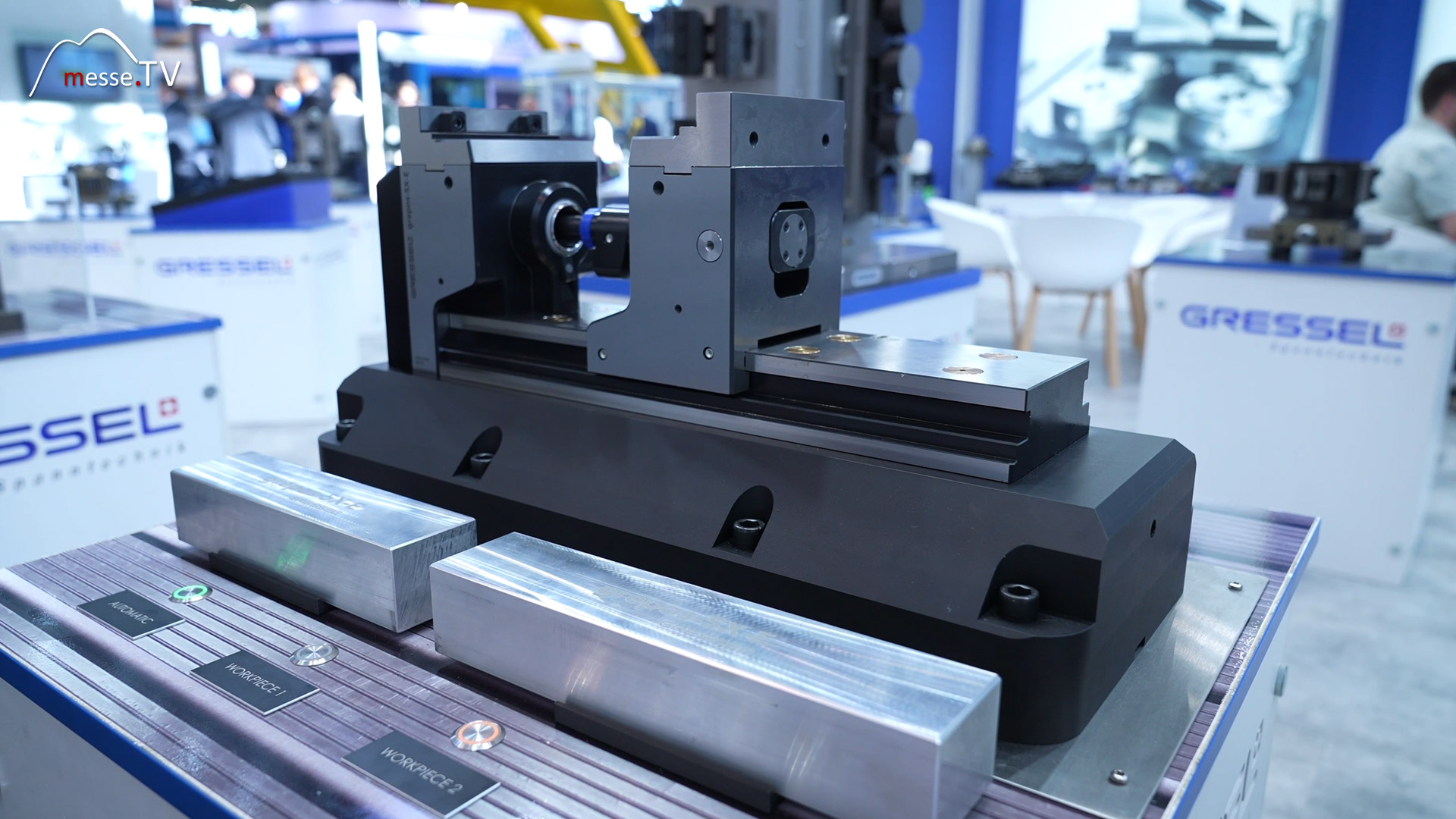

Robot modules for small series and single-part production

The R-C2 robot module offers a flexible solution for small series and single-part production. The module controls mechanical vices that act as grippers and pallets. This allows workpieces to be clamped and processed without manual intervention. This automation enables efficient production overnight, while individual parts can be manufactured during the day. An integrated cleaning system ensures that chips and coolant remain in the machine, further optimizing the automated process.