Kelch GmbH is a leading supplier of precision tools, tool presetters and measuring equipment for the machining industry. With over 80 years of experience, the company supports customers worldwide in optimizing their manufacturing processes with innovative products and comprehensive services. Kelch offers solutions to increase the performance of machine tools, including modern tool logistics and shrink-fit technology. A particular focus is on digitalization and automation to maximize efficiency in production.

The new "Saline V 244" tool presetter from Kelch impresses with its compact design and user-friendly handling. With a height and diameter of 400 mm, it is particularly space-saving and can be placed directly on the table without compressed air. The tools are measured quickly and precisely thanks to various adapters for HSK and SKS tools, which can be used flexibly.

The specially developed kOne software from Kelch, equipped with a 24-inch touch monitor, enables intuitive operation of the device. With the help of a laser pointer and lighting, the tool is moved exactly onto the cutting edge, allowing precise measurements to be taken. The software creates shadow images of the tools and ensures optimum measuring accuracy - whether for individual cutting edges or the entire tool.

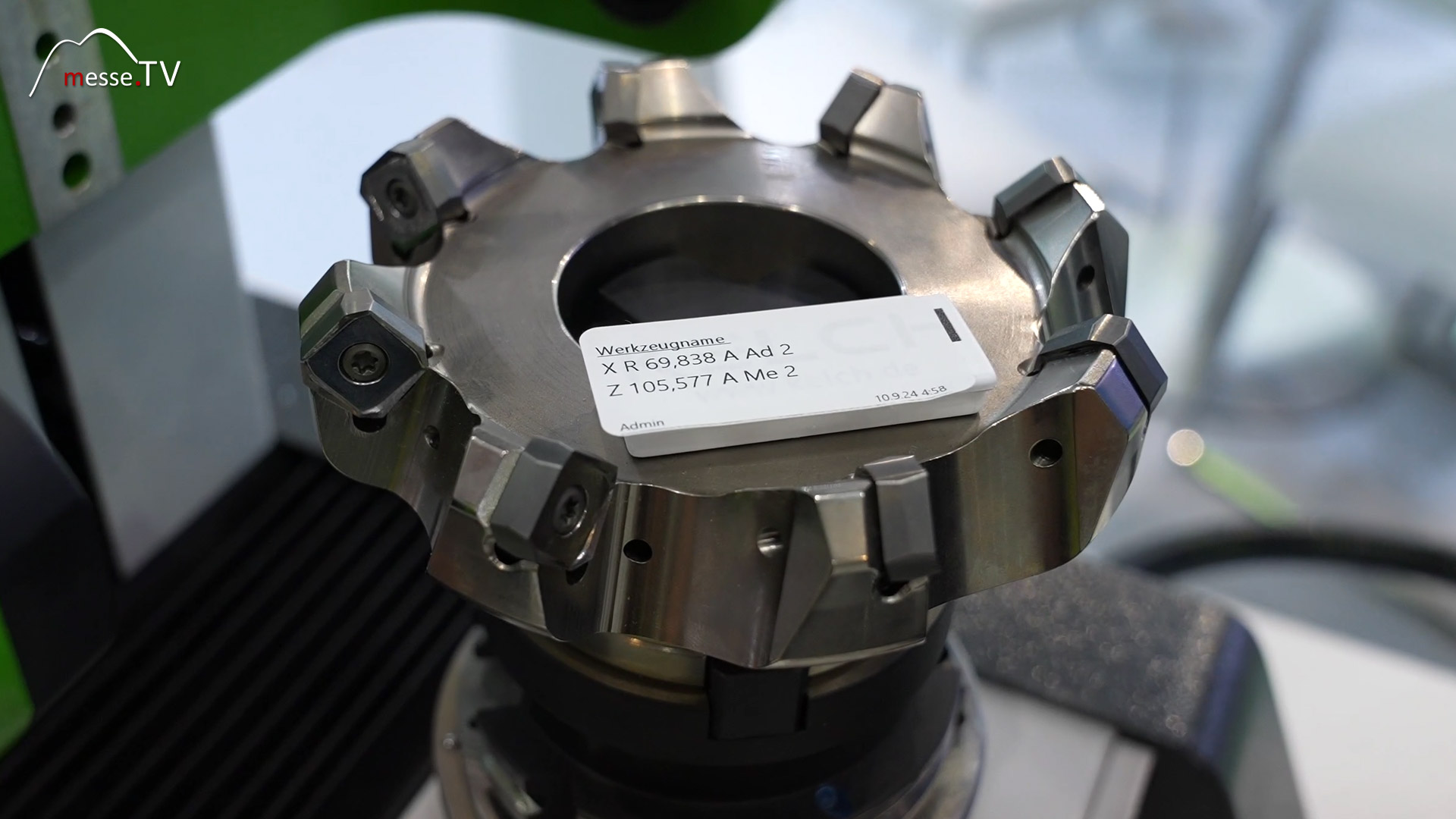

By using the Kelch software and the option of printing labels with QR codes or Ballhof chips, the risk of human error when transferring the measured values to the machine is minimized. This not only ensures process reliability, but also saves valuable time, as the tools no longer have to be measured on the machine itself. Another advantage is the simple integration into existing networks so that the measurement data can be transmitted directly to the machine control system.