Robotics for efficient automation: process optimization in industry

In modern industry, companies are under increasing pressure to optimize their processes and make them more efficient. A fundamental topic is therefore: "Robotics for Efficient Automation: Process Optimization in Industry". In this way, we offer a comprehensive insight into the transformative role that robot technologies play in increasing productivity and cost efficiency. Through automation, companies can not only strengthen their competitiveness, but also shorten their production times and reduce error rates. Discover how innovative robotics solutions can revolutionize your operations and give you an edge in the fast-paced global economy.

Brief overview

Robotics plays a transformative role in the industry by dramatically increasing both efficiency and cost effectiveness. Companies that adopt innovative robotics solutions early on can shorten their production times and reduce the error rate. By integrating modern technologies into existing systems, companies secure decisive competitive advantages and prepare themselves for the future. Get valuable insights from our guide and find out how robots can revolutionize your production processes.

Most important highlights

- Robotics increases industrial efficiency through automation and reduces production times and error rates.

- Intelligent robotic systems enable precise, reliable and cost-effective production processes.

- Integration of robotics requires careful planning and training for optimal interaction with existing technology.

- The robotics association supports the industry with research projects and innovation funding for industrial applications.

- Strategic planning and partnerships are crucial for successful robot integration into business processes.

The role of robotics in process optimization

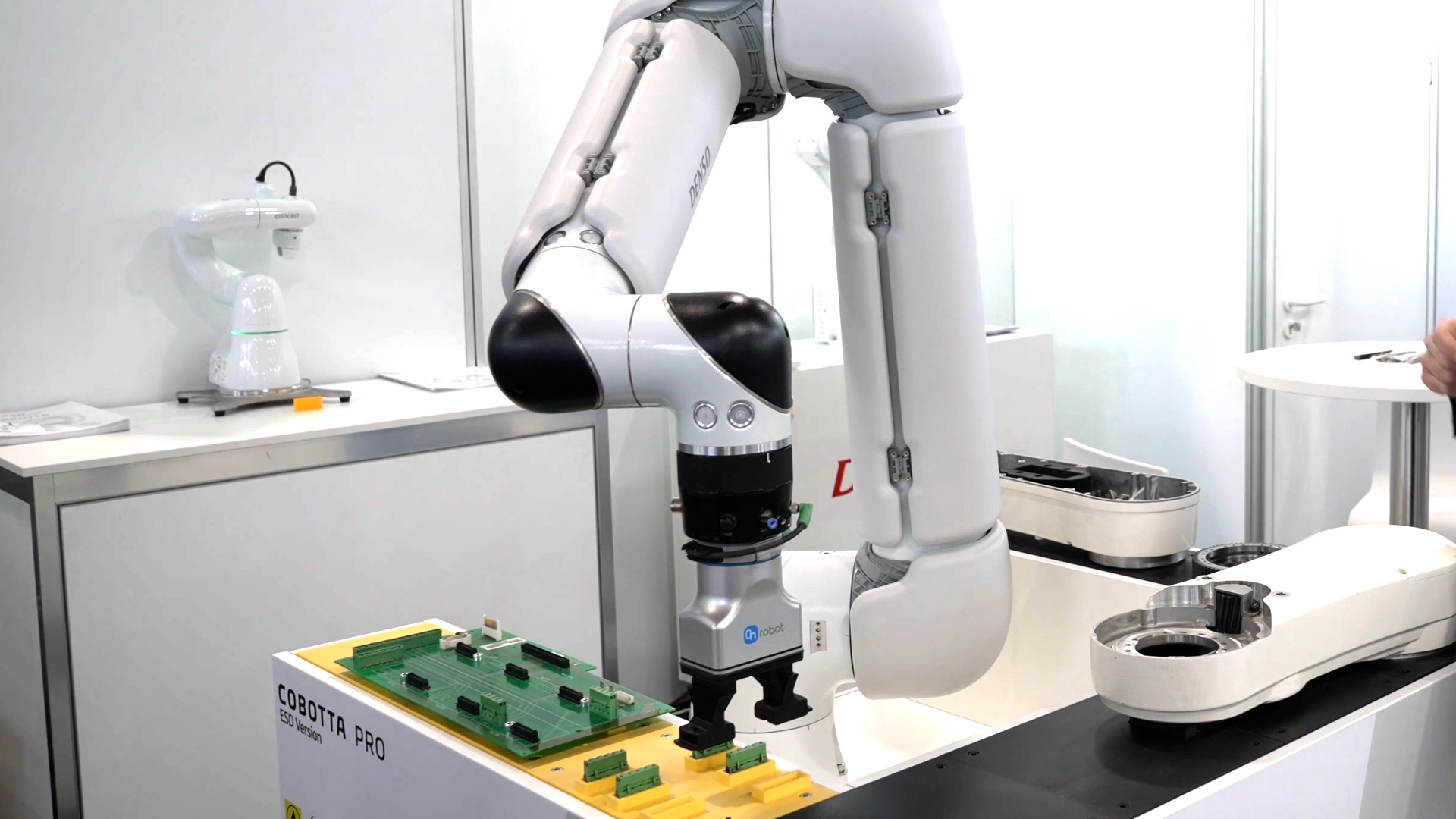

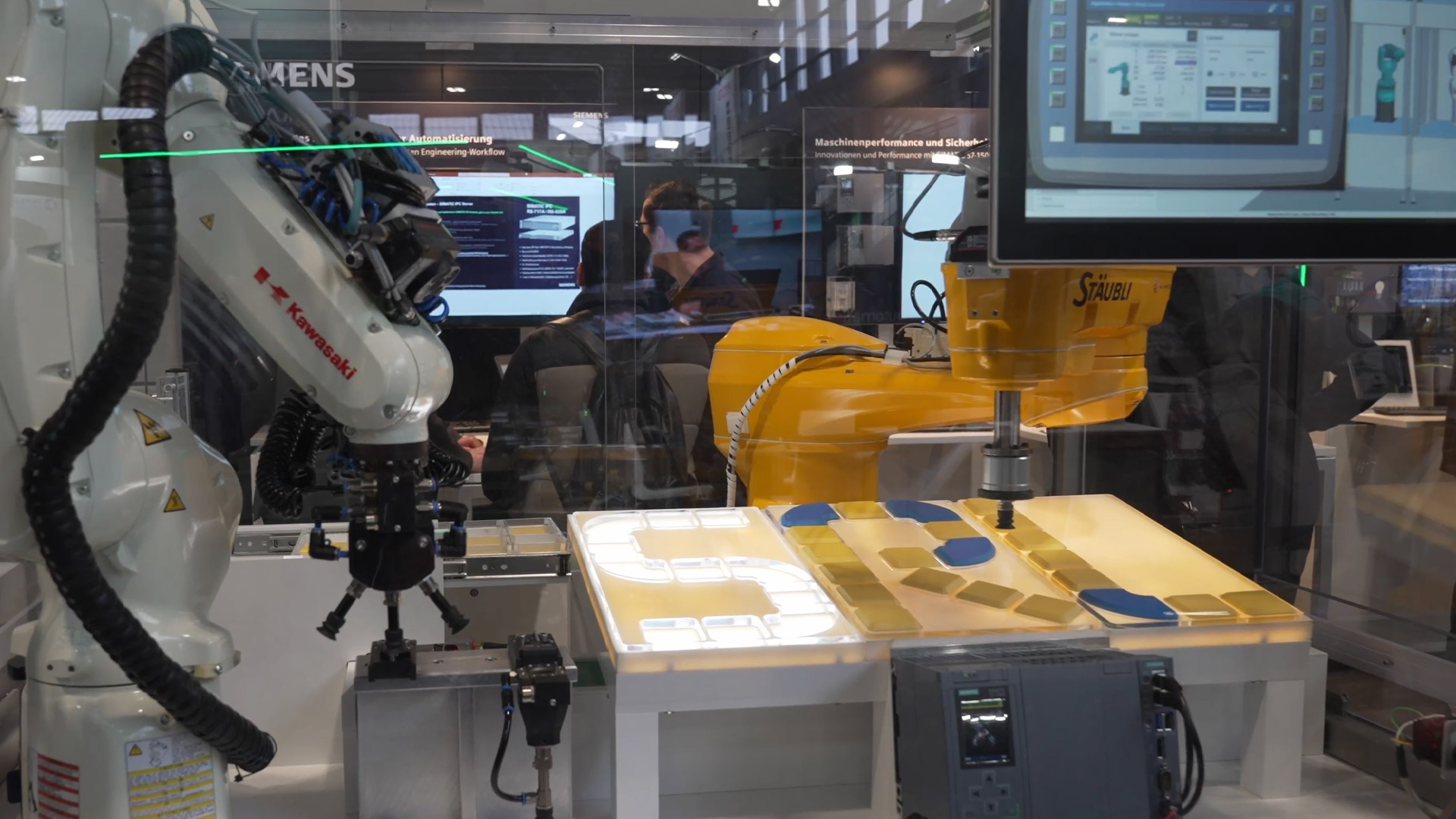

In the dynamic world of industry, process optimization is at the heart of technological innovation. Robotics integration has taken on an essential role in this by not only drastically increasing efficiency, but also creating new possibilities for the production environment. These intelligent machines, equipped with advanced intelligence, are revolutionizing production lines with precise, reliable and cost-effective solutions. The future of automation is based on intelligent robotic systems that integrate seamlessly into the industrial landscape. We will now explore in detail how these systems achieve efficiency gains, the benefits they bring and the revolutionary changes they promise to bring to engineering and production in the coming decades.

Increased efficiency through the use of robotics

The strategic use of robotics in production processes achieves a remarkable increase in efficiency. Robots working with state-of-the-art artificial intelligence (AI) can perform tasks with a precision that exceeds human standards. This ability to perform tasks autonomously not only leads to a reduction in production costs, but also significantly shortens cycle times. Intelligent data processing and real-time analysis enable robotic systems to respond proactively to production problems, reducing downtime. This optimizes the production process and at the same time ensures the quality of the end products.

Best practices for robot applications in the industry

Companies are increasingly turning to robotics to increase efficiency in production and gain a competitive edge. In this section, we highlight the integration of robotic applications into existing systems and how such best practices can smooth the transition. With a focus on constant progress and adaptation, we show how German robotics development, together with institutions such as the Fraunhofer IEM, is contributing to the further development of industrial processes. These strategies provide valuable insights to successfully implement innovations and enable long-term improvements.

Integration of robotics into existing systems

The integration of robotics into existing systems is a decisive step towards achieving sustainable process improvements in industry. Technologies such as artificial intelligence and computer science play a key role in this. By combining existing technology with new technology, companies can create flexible, efficient and highly customizable production lines. The Fraunhofer IEM is an excellent example of the innovative power of German robotics applications. Its research helps companies develop models that enable seamless integration and ensures that the implementation of robots leads to significant productivity gains.

A key to successful integration is careful planning, which ideally involves all departments - from the production floor to IT. This ensures that the system requirements are coordinated and that the new robots can interact efficiently with the existing machines. Companies that integrate robotic solutions benefit from reduced error rates and accelerated production time without compromising quality. Employee training is also an important part of successful integration. They should be familiarized with the new technologies in order to optimize the collaboration between man and machine. Training programs allow employees to take maximum advantage of robotics capabilities while learning new skills that will improve their career opportunities. Through strategic implementation and dedicated employee training, the topic is becoming a driving force for innovation in the industry and is thus significantly shaping the future of modern manufacturing processes. With solid best practices that can be seamlessly integrated into existing operations, companies are not only creating a more efficient production environment, but also a smarter one.

The Robotics Association's contribution to industry development

The Robotics Association plays a key role in promoting the industry through various research and lab initiatives. These initiatives are designed to develop innovative solutions that increase both the efficiency and integration of robotics solutions in industrial applications. The association also plays a crucial role in education through degree programs that focus on the needs of modern industry. Below we take a closer look at the role of these initiatives, including social and intellectual aspects, in the development of the industry.

Research and lab initiatives for innovative solutions

The Robotics Association in Germany has established itself as a key figure in the promotion of research and development. Through its diverse research projects, pioneering technologies and applications in robotics are being advanced. In cooperation with renowned institutes such as Fraunhofer, the association researches new methods for implementing social robotics and developing social robots that can be used in industry and beyond. This is done through targeted lab initiatives that focus on innovative robotic solutions that can significantly increase productivity in manufacturing and other industries. Within these labs, concepts are developed that address the challenges of modern production processes. By integrating methods from artificial intelligence and computer science, systems are created that are able to handle complex tasks autonomously and efficiently. The association actively promotes robotics courses that offer young engineers the opportunity to familiarize themselves with the latest technological developments as part of their studies. The course offers training for a new generation of specialists who are ideally prepared to implement innovative solutions in the context of Industry 4.0.

In addition to technological development, the establishment of social robots is another key focus. These robots are designed to interact with humans and are becoming increasingly important in various industries such as healthcare, logistics and production facilities. The association supports research into "intelligent robotics", which aims to develop robots that are not only efficient, but also safe and user-friendly. Through its research and lab initiatives, the association contributes significantly to the innovative strength of German industry. With a clear focus on the future of automation, it succeeds in both optimizing established processes and opening up new areas of application for robotics. Companies that rely on these innovative solutions are in a better position to meet the challenges of the global economy and secure long-term competitive advantages.

Planning and implementation of robot solutions in the company

With the increasing complexity and speed of industrial processes, implementing robotics solutions is a crucial step in increasing a company's efficiency. The right planning and implementation of these solutions can bring significant benefits, from increasing productivity to reducing costs. Especially in challenging production environments, precise robots help maintain quality standards while maximizing output. Because robots can work tirelessly, without fatigue or error, they play an essential role in maintaining consistent production processes. This not only means an increase in productivity, but also a significant reduction in error rates and production downtime. In this section, we look at the detailed planning that is crucial for the successful integration of robotics into business processes. Above all, understanding and correctly applying modern technologies can provide a decisive competitive advantage.

Strategic planning for successful robot integration

Strategic planning is the cornerstone of successful robot integration and begins with a comprehensive analysis of existing company processes. This analysis serves to identify automation potential and define specific requirements. Companies should not only use their own knowledge for this, but also entrust experts such as the Fraunhofer IEM, which offers customized solutions with its comprehensive expertise in robotics and electrical engineering. A strategic partnership with such institutions can make it easier for companies to access emerging technologies and use them effectively.

For global companies, it is particularly important to understand local market characteristics and cultural nuances in order to adapt robotics solutions to regional requirements. This often requires a profound restructuring and re-planning of personnel processes, which must go hand in hand with the advancement of technology. AI robotics expertise is particularly important here, as it can circumvent potential international obstacles. With the right strategic planning, companies can minimize downtime and ensure that robotic solutions are profitable not just in the short term, but in the long term. The interdisciplinary approach helps to achieve these goals by combining technological and business perspectives. This makes a decisive contribution to how well a company is prepared for future challenges and can react to new market requirements.

Robotics for efficient automation opens up undreamt-of potential for companies in terms of process optimization. The strategic use of robots not only shortens production times, but also significantly increases quality and consistency. Companies that integrate these technologies at an early stage secure decisive competitive advantages and create future-oriented production environments. Take the opportunity now to talk to one of our experts and discover how robotics can optimize your processes. Download our comprehensive guide and find out more about the latest trends in industrial automation.