System Square develops high-precision X-ray inspection systems for foreign body inspection in the food industry. These systems offer reliable quality control and can also detect foreign bodies in aluminum packaging. Thanks to innovative technology, the machines are extremely sensitive and low-maintenance, which increases the safety and efficiency of food production.

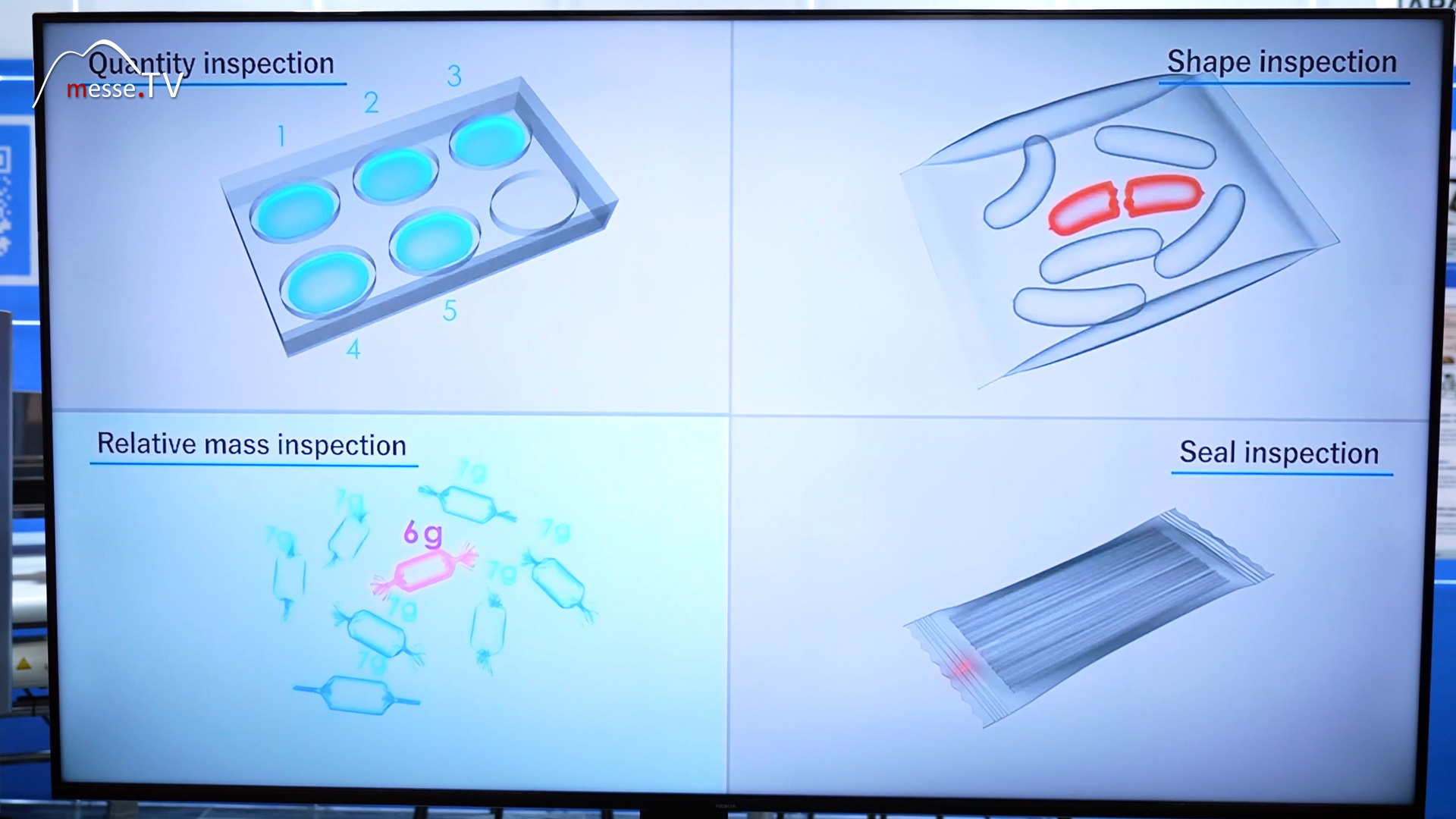

The X-ray machine presented combines imaging technologies to reliably detect damage and irregularities in food packaging or other products. A key feature is the ability to identify damage in seals - a crucial factor in the quality control of packaged goods, such as sliced meat products. If slices slip in the packaging and get caught in the seal, this often remains undetected, which could spoil the goods. The patented system enables seamless inspection and detects even the smallest foreign objects or breakages that would not be visible using conventional methods.

By using artificial intelligence, the device can also detect objects or damage that escape the human eye, such as small stones in olives. With the help of algorithms that apply mathematical filters, foreign objects are detected precisely and reliably. This AI technology is based on years of development and makes it possible to inspect products with unprecedented accuracy. Unlike standard X-ray machines such as those used at airports, this system uses special algorithms that are precisely tailored to the requirements of the food industry.

While the use of such technologies is already widespread in Japan, demand in Europe is steadily increasing. Supermarkets and end consumers in particular are demanding products that meet the highest quality standards and have been thoroughly tested. The pressure on manufacturers to offer quality-controlled products is growing. Companies are increasingly willing to invest in this technology, which costs between 40,000 and 150,000 euros, depending on the model and scope of the application.