Pamminger is a leading company in the field of packaging technology, conveyor technology and mechanical engineering with over 90 years of experience. The company develops and produces innovative machines and systems that are used particularly in automotive and space research. Pamminger attaches great importance to quality, precision and durability, with all products manufactured in regional production facilities to ensure the highest standards.

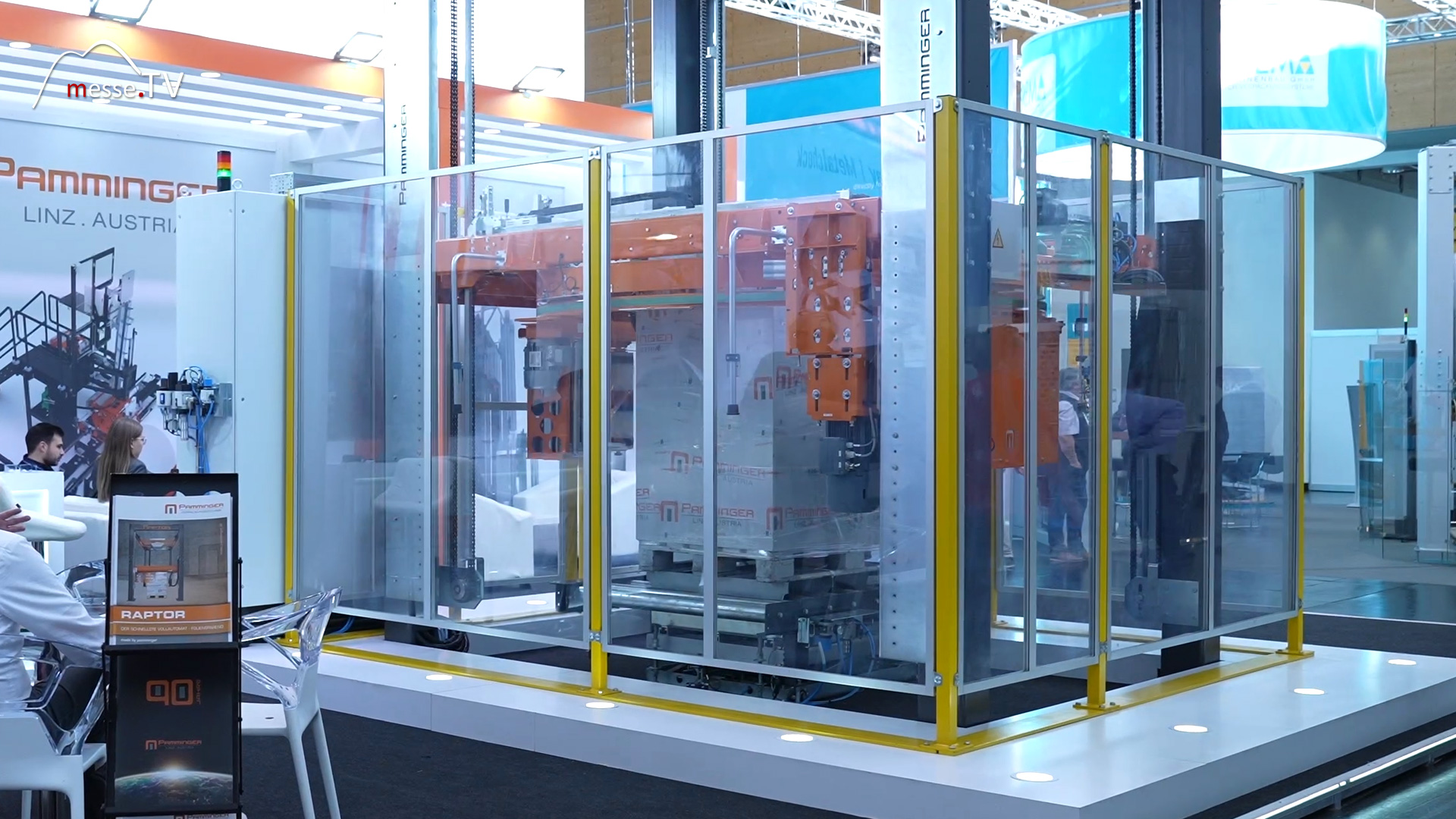

End-of-line packaging plays a crucial role in securing load units. The aim is to secure the goods on pallets in such a way that they do not fall apart in the event of emergency braking or acceleration. This protection is ensured with so-called tertiary packaging. By using state-of-the-art technologies such as the Raptor system from Pamminger, this is not only cost-efficient but also environmentally friendly, as film consumption is reduced to a minimum.

The special feature of this packaging technology is the ability to pre-stretch the film by up to 500%, which can be adjusted as required. This not only saves material, but also ensures the stability of the load. With intelligent programming, the machine adapts the pre-stretch values and the amount of film required individually to the contours of each pallet. This leads to a significant reduction in film consumption - by up to 30 grams per pallet - without compromising safety.

This innovative packaging technology from Pamminger is ideal for various industries, from the food and beverage industry to the building materials industry. Thanks to the high flexibility of the machines, they can adapt to different requirements, whether for continuous operation with 100 pallets per hour or for faster throughputs with smaller production quantities. This versatility makes the system attractive for companies of all sizes and in all industries that value efficient and reliable packaging solutions.