Kleemann MSS 1102 Pro: New performance class for coarse screening plants

With the MSS 1102 Pro, Kleemann is expanding its machine portfolio with a new high-performance plant for processing natural stone and recycling material. The mobile screening plant is designed for use in quarries, open-cast mines and recycling yards. As the largest screening plant in the range, it closes a gap in the upper performance range and sets new standards in terms of throughput and flexibility.

Largest screening area in the Kleemann portfolio with up to 750 tons per hour

The MSS 1102 Pro is currently the most powerful coarse screen from Kleemann. With a screening surface of 11.2 square meters, it achieves a maximum throughput of up to 750 tons per hour. It is typically used in quarries and open-cast mines, especially when processing loamy natural stone. The application shown here involves material from an intermediate layer in the quarry, which requires efficient screening due to its properties.

Material feed via hopper with a volume of 12 cubic meters

The raw material is fed into a generously dimensioned feed hopper with a volume of 12 cubic meters. From there, it is fed into the screen box, where it is screened over two decks. The 11.2 square meter screening surface offers sufficient capacity to process even large quantities of material quickly. The version presented here does not have a central grain belt installed. This means that material from the upper deck and the overflow from the lower deck fall together onto the main discharge belt and are transported onwards together as a coarse grain fraction - for example to a downstream crusher.

Fine grain screening via separate discharge belt

The material that falls through the lower deck is discharged via a separate fine grain belt. This fraction usually consists of fine, hardly recyclable material, which is usually deposited in landfills. The clear separation of coarse grain and fine grain means that plant operation can be organized efficiently and optimally adapted to the subsequent recycling route. The design of the MSS 1102 Pro enables an even distribution of material over the entire screening surface, which improves the separation quality.

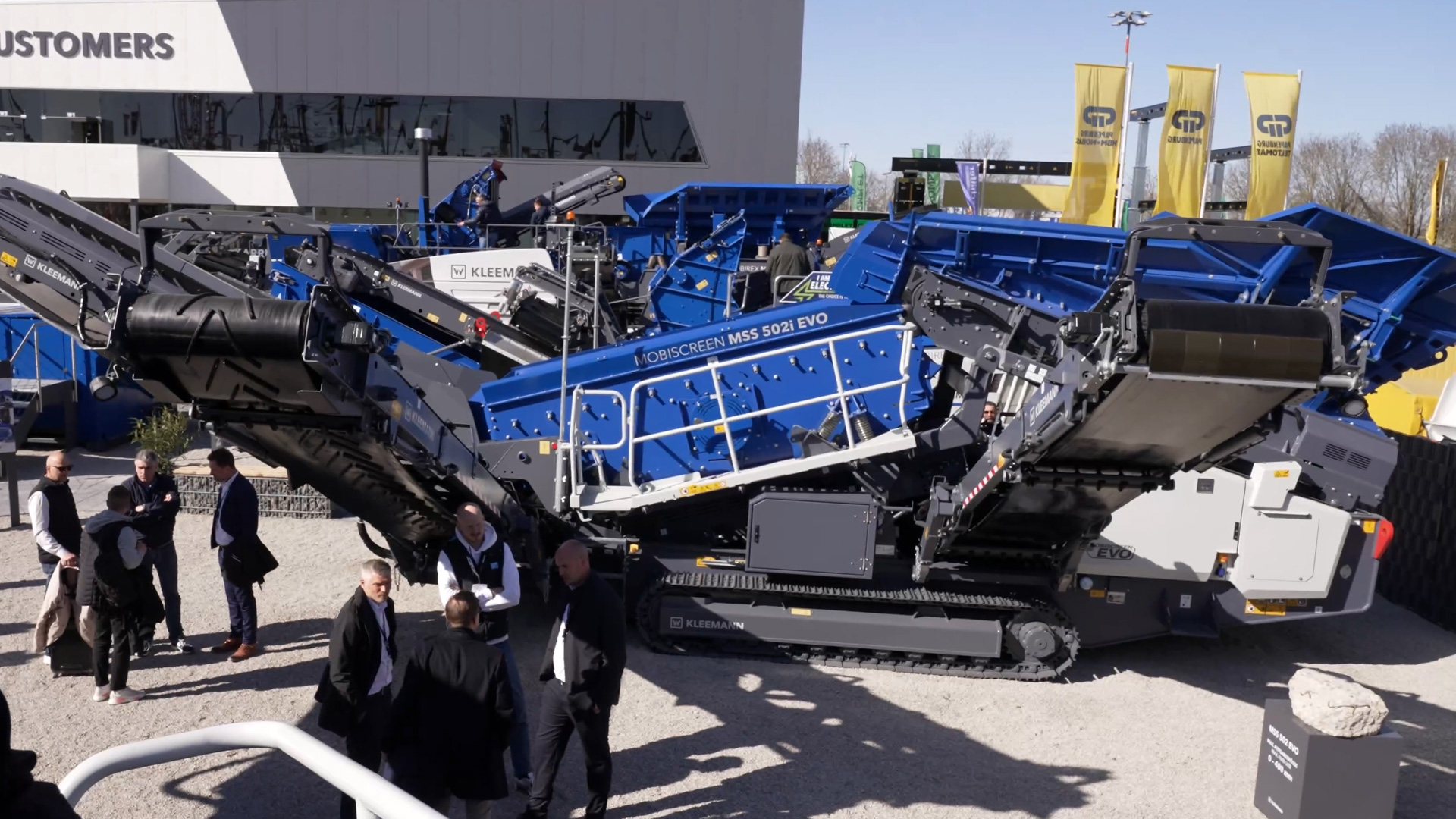

Upward expansion of the Kleemann screening plants

With the new system, Kleemann is rounding off the top end of its coarse screen portfolio. The MSS 1102 Pro will form the upper end of the model range in future. Below this machine is the MSS 802, which will also be presented at the trade fair stand. The entry-level model in this segment is the MSS 502 Evo. While the 502 operates in the range of around 350 tons per hour, the 1102 Pro achieves more than double this capacity with up to 750 tons. The basic design is the same for all machines, including the operating concept and equipment features. The main differences lie in the respective performance class and the possible conveying capacity.

Flexible classification of three fractions in recycling

The MSS 1102 Pro is not only suitable for natural stone, but also for use in recycling or soil processing. Specific screening surfaces are often used here - such as a 100-millimeter perforated plate in the upper deck. Material larger than 100 millimetres is discharged via the main discharge conveyor. The middle grain range of around 30 to 100 millimetres can be discharged separately, provided a middle grain belt is installed. Fine grain below 30 millimetres is discharged via the fine grain belt. This precise separation into three fractions enables targeted material recycling and increases the efficiency of the recycling process.

Compact belt design for tight spaces

Kleemann offers a version of the smaller MSS 502 Evo with both discharge conveyors on the same side for use in confined spaces such as inner-city recycling areas. This configuration makes it easier to feed bulk material boxes and improves the use of space in confined areas. Users benefit from simplified logistics, as the material can be collected directly at the discharge point without deflection.

Electric drive technology for CO₂-free operation

A central theme at the Kleemann stand is the electrification of plant technology. All of the screening plants on show can be operated electrically and can be operated emission-free on site - a growing demand from many customers, particularly in the municipal and industrial sectors. The elimination of diesel units not only reduces CO₂ emissions, but also the noise level on site. The motto "Be Electrified" underlines the strategic focus on sustainable technologies.

Mobile control and new radio remote control as an option

As with all Kleemann screening plants, the MSS 1102 Pro is controlled via a central operating unit that displays all plant functions - from the diesel fill level to the control of individual conveyor belts. A new feature of this model is the optional radio remote control. It enables remote control of functions via two toggle switches and proportionally controlled joysticks. The operator can position himself freely within range and carry out movement sequences safely and precisely - a real added value in daily operation.