Pure insulation materials: Sustainable solutions at BAU 2025

Puren GmbH is a German manufacturer of high-performance polyurethane (PU) insulation materials based in Überlingen on Lake Constance. The company develops and produces innovative insulation solutions for various areas of application, including pitched roofs, flat roofs, façades, floors and ceilings. puren pays particular attention to sustainability and resource conservation, for example through the use of the functional material purenit®, which is made from production by-products and construction site offcuts. With over 50 years of experience, puren is one of the pioneers in the PU insulation industry and offers solutions for architecture, planning, specialist retailers, trade, industry and OEMs.

Purenit: Sustainable material innovation for versatile applications

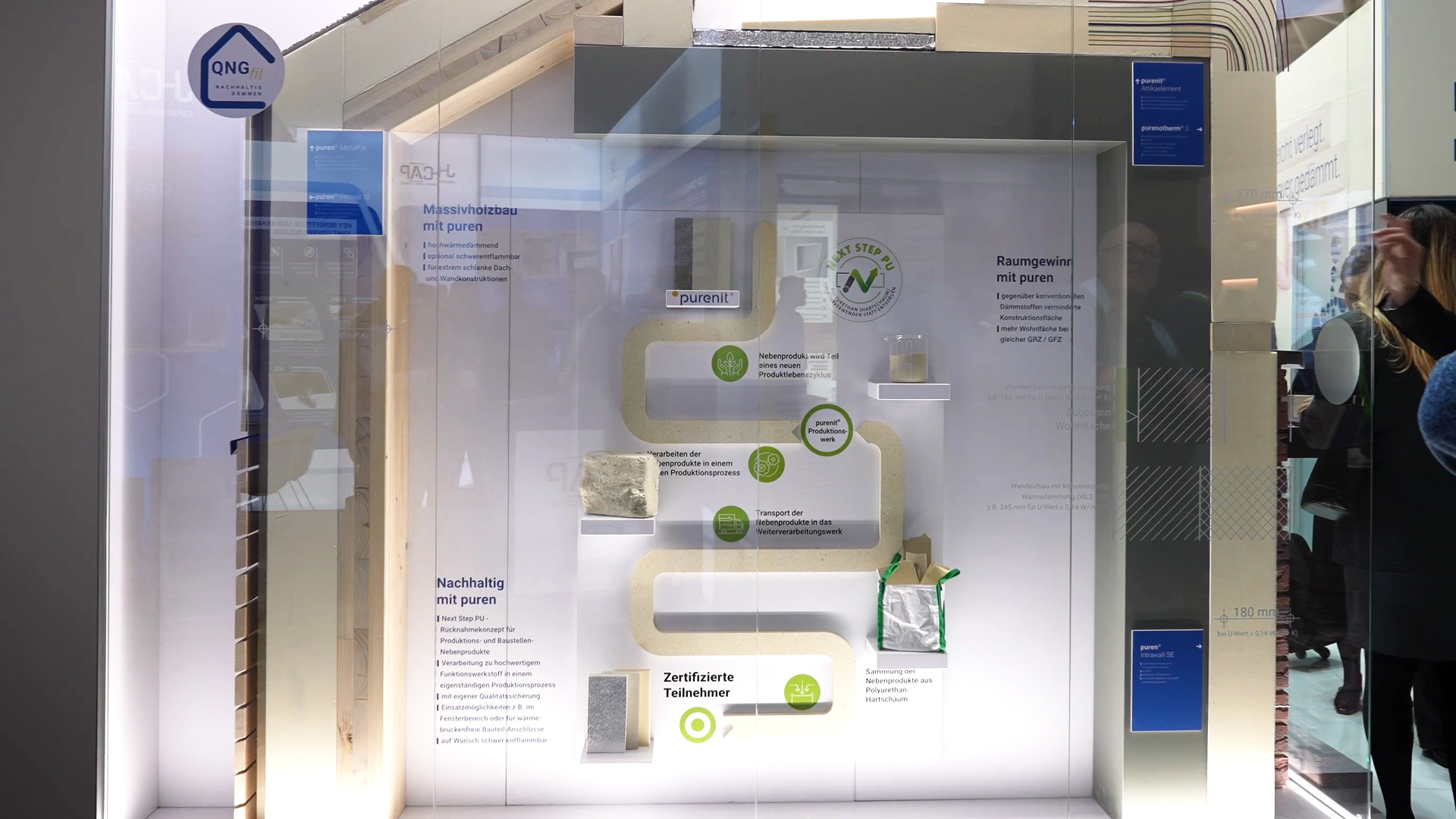

Purenit is an innovative material produced by Puren from polyurethane production waste. This sustainable use of resources follows the "Next Step PU" concept, which aims to integrate materials into a new life cycle and reprocess waste in a meaningful way. A highly compacted material called Purenit is produced by pressing and grinding the polyurethane waste. This is characterized by particular stability and a high bulk density, which makes it versatile, especially in areas where wood reaches its limits.

Water resistance and mold resistance: advantages of Purenit

A key advantage of Purenit is its resistance to moisture. Even in direct contact with water, the material retains its shape, does not swell and retains its consistency. It is also resistant to mold, which makes it ideal for applications in damp environments. These properties make Purenit an excellent alternative to wood, as it can also be used where conventional wood-based materials fail.

Easy to process and ideal for construction applications

Purenit not only impresses with its material properties, but also with its ease of processing. It can be processed with the same tools that are used for wood, such as saws or cutting machines. The wood-like workability combined with superior water and dimensional stability makes Purenit a versatile building material that can be used in numerous construction applications.

Focus on sustainability and reusability

Purenit is a prime example of sustainable material development. As it is obtained from production residues, it contributes to waste reduction and significantly extends the life cycle of polyurethane. In addition, Purenit can be recycled again after use and transferred to another life cycle. This underlines Puren's commitment to sustainability and resource conservation. Thanks to its versatility and attractive price-performance ratio, Purenit offers innovative solutions for a wide range of applications and sets new standards in sustainable material development.