HECO is a German manufacturer of screws and fastening solutions based in Schramberg. The company offers products such as the HECO-TOPIX-plus wood screw, which was developed for demanding applications in timber construction. In addition to developing innovative products, HECO focuses on certified production standards and technological advancements.

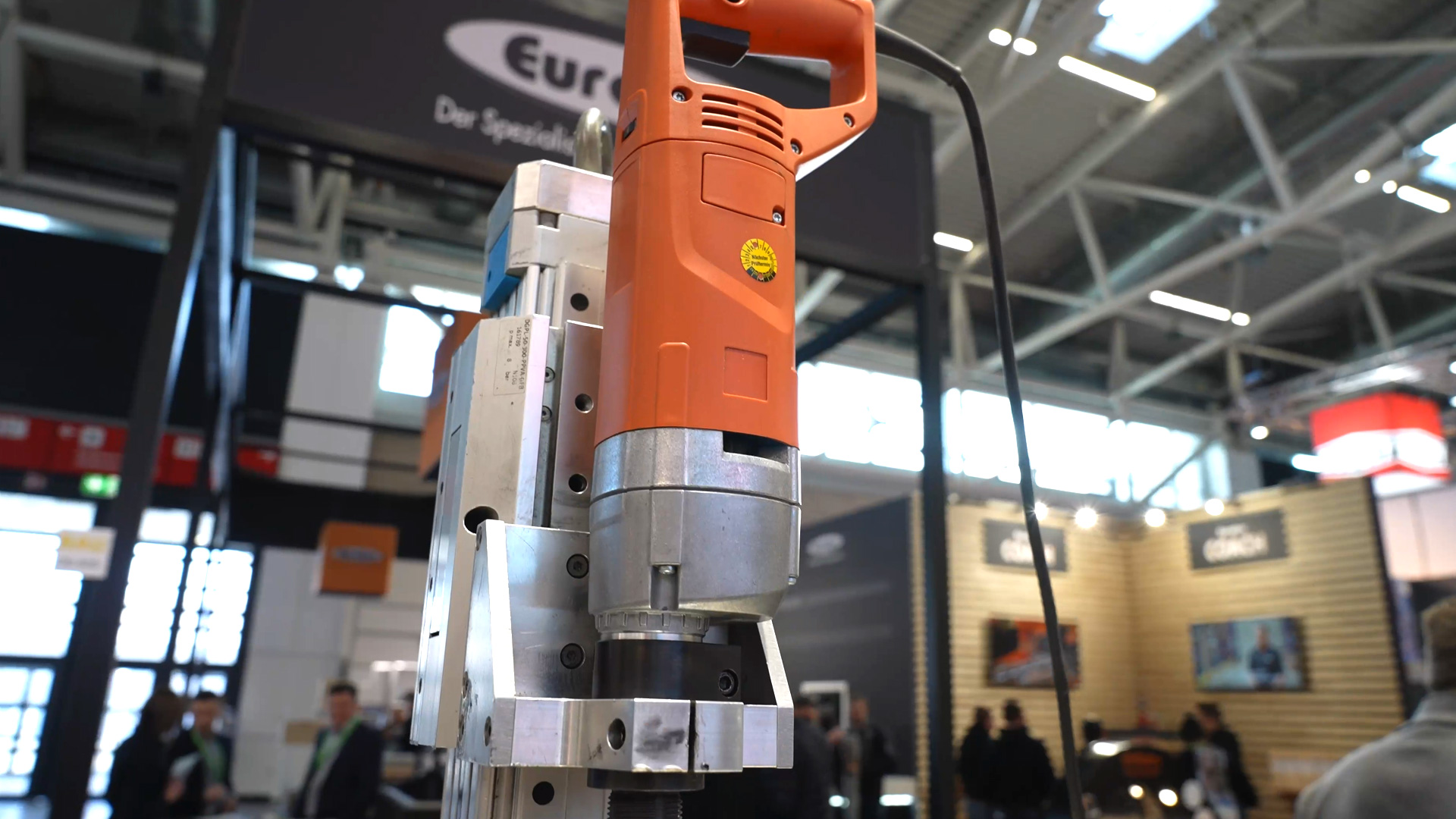

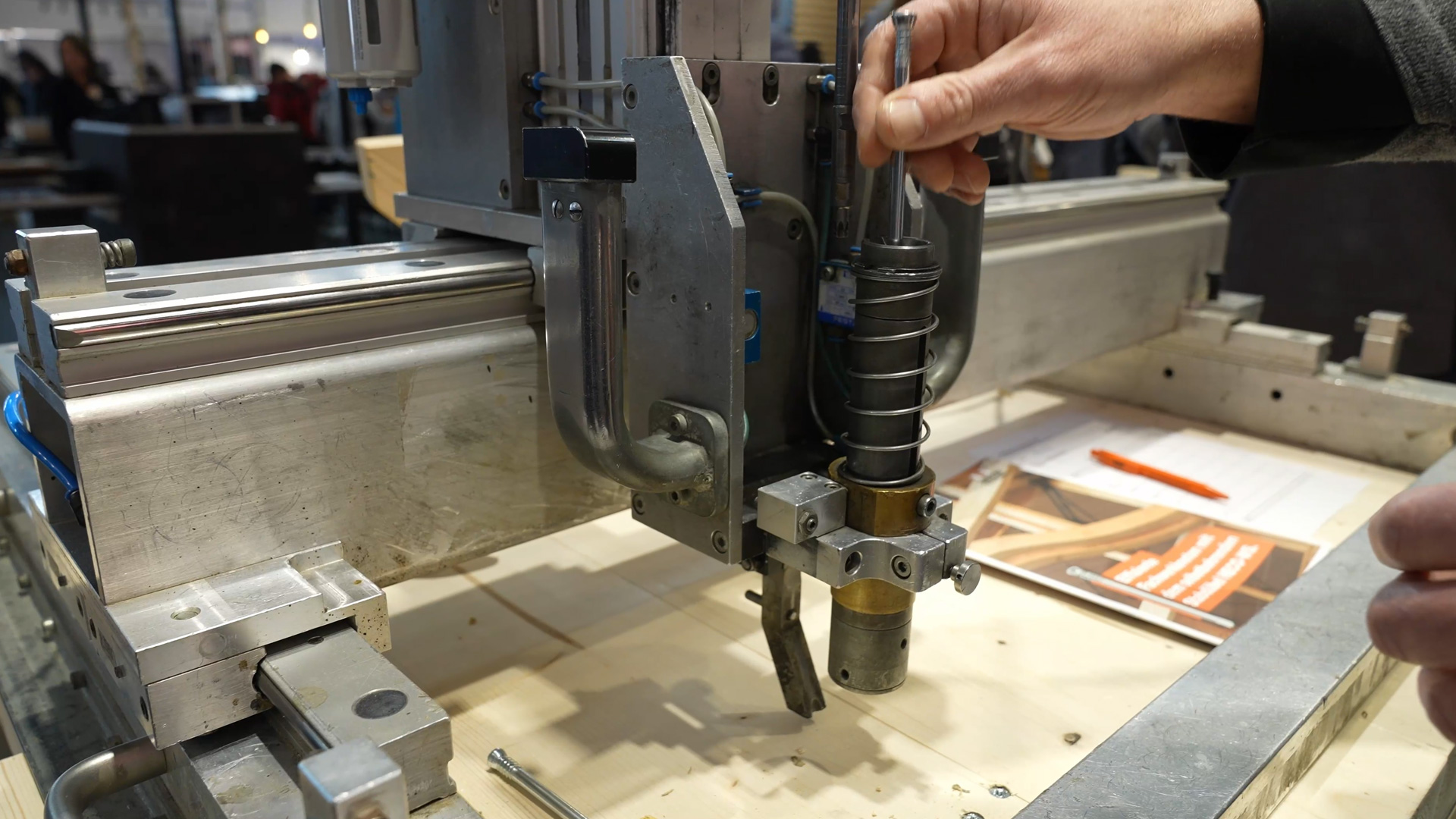

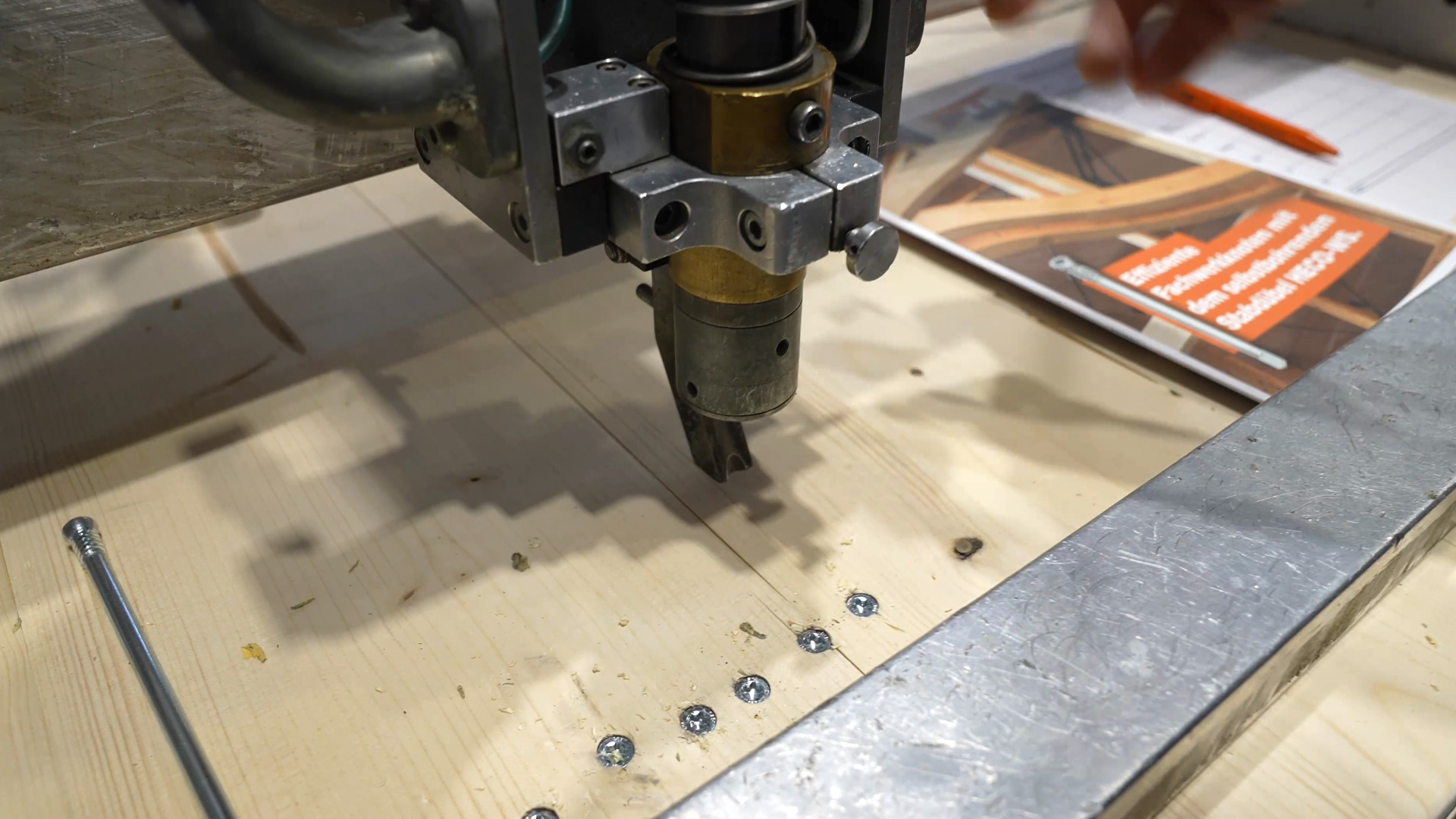

The setting tool for HECO-WS rod dowels revolutionizes the processing of slotted wood-steel joints through a combination of efficiency, precision and safety. With this tool, wood and steel can be drilled through and the rod dowels precisely set in just one operation. The setting tool impresses with a specially developed cutting plate that cuts effortlessly through 10 millimeter thick steel plates as well as triple-layered 5 millimeter steel plates. This technology significantly reduces the hole clearance and enables a particularly stable connection. The design with a central timber between the steel plates provides additional strength and minimizes potential weak points. This unique way of working not only saves time, but also ensures accurate and even placement of the dowels, which is often a challenge with traditional methods.

The device was specially developed for applications in the field of modern timber construction, where precise connections between timber and steel components are required. A major advantage is the ability to efficiently implement fire protection requirements. For this purpose, the rod dowels are inserted 20 millimeters deeper into the material and then covered with cross-wood plates. This invisible connection effectively protects the steel parts from direct exposure to flames and complies with the applicable fire protection regulations. This technique also ensures an aesthetically pleasing appearance, as no visible metal parts remain. Covering not only makes the connection safer, but also more visually appealing, which is particularly advantageous for visible structures in timber construction.

In addition to precision, the setting tool places particular emphasis on maintaining the ductility of the wood. Thanks to the ability to use thin fasteners, the wood is prevented from becoming brittle, even when using larger rod dowels with a diameter of 16 millimetres. This property is particularly important to reduce stresses in the joint and ensure long-term stability. The ductility allows the joint to move minimally without losing its structural integrity, significantly extending the life of the structure. At the same time, the precise drilling and placement of the rod dowels ensures even load distribution and minimizes the risk of material failure.

The setting tool not only offers exceptional precision, but also saves valuable working time. All the necessary steps are carried out in a single operation, eliminating the need for manual reworking or corrections. The ease of use of the tool allows even less experienced users to achieve professional results. Thanks to its versatility, it is suitable for a wide range of applications, from classic timber construction projects to specialized constructions where both stability and aesthetics play a role. The setting tool shows its strengths particularly when working with joints that are difficult to access or complex, making it an indispensable tool for professional timber construction.

The setting tool for HECO-WS rod dowels combines state-of-the-art technology with maximum functionality and sets new standards in the field of connection technology. It not only enables precise and stable connections, but also fulfills demanding fire protection requirements. The simple operation, the reduction of hole clearance and the preservation of the ductility of the wood ensure professional processing. This solution not only makes work in timber construction more efficient, but also safer and more durable.