LPKF Laser & Electronics SE, headquartered in Garbsen near Hanover, is a global technology company specializing in laser technology, precision mechanics and software. LPKF has been developing innovative processes for the production of printed circuit boards, microchips, automotive parts, solar modules and other components since 1976. With over 750 employees and subsidiaries in Europe, Asia and North America, the company offers solutions for miniaturization and precision in various industries.

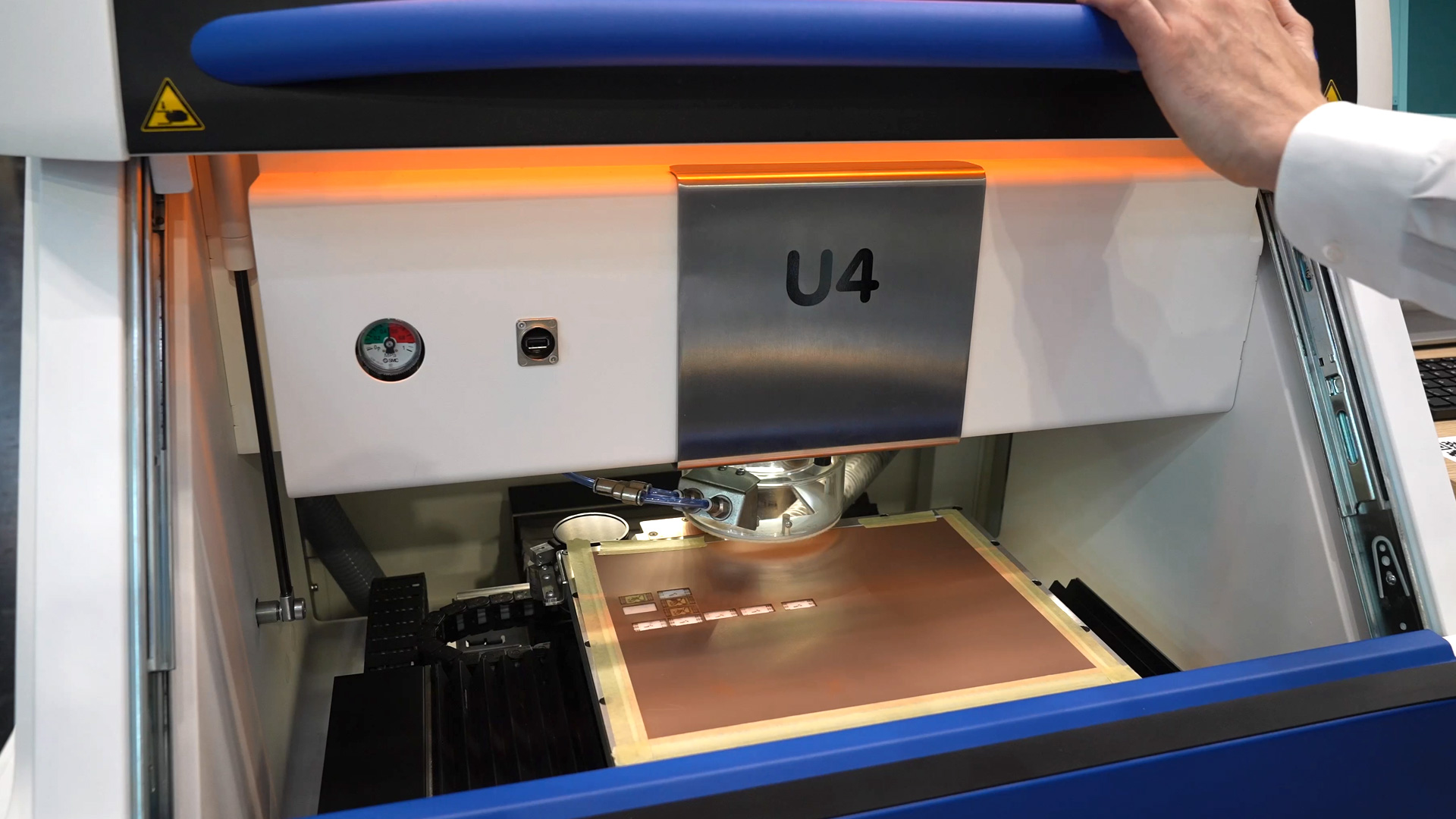

LPKF's ProtoLaser U4 is a powerful PCB prototyping system that enables the fast and precise creation of printed circuit boards. This system supports single-sided and double-sided PCBs and is ideal for developers looking for flexible and efficient manufacturing options. With the integrated UV laser, various materials can be processed in a structured manner, holes can be drilled and the PCBs can be cut out cleanly. The ProtoLaser U4 thus creates an end-to-end manufacturing solution that significantly speeds up the prototyping process.

The ProtoLaser U4 enables a wide range of material processing and is ideal for flexible PCBs, ceramics and even high-frequency and microwave applications. The system's UV laser ensures high-precision structures that are often difficult or impossible to achieve with mechanical processes. This versatility and precision make the system the ideal choice for development departments, universities and research institutes that rely on prototyping and fast material processing.

The ProtoLaser U4 is aimed specifically at developers and researchers who want to carry out the entire prototyping process in-house and maximize their flexibility and speed. Research institutes and universities use the system to react quickly to design changes and create prototypes in a timely manner. LPKF offers a suitable solution for every requirement and every material, making the ProtoLaser U4 a future-oriented investment for development departments that rely on precise and fast PCB prototyping.