The company InspecVision specializes in 2D and 3D measurement technology. The highlight at Blechexpo 2023 is a combined system that can measure both 2D and 3D parts.

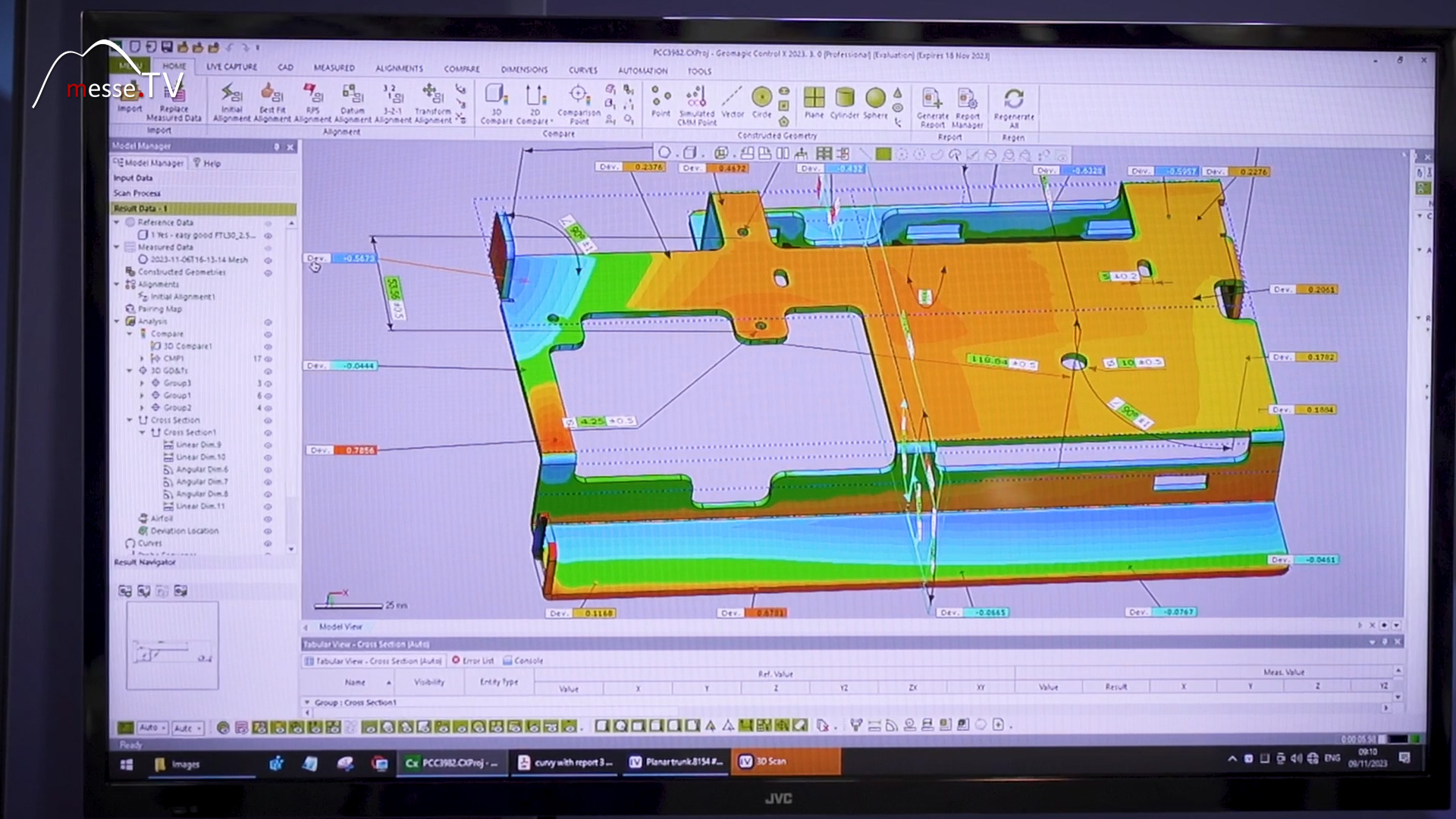

2D and 3D measurement technology is the profession of InspecVision. This is what the Northern Ireland-based company specializes in. 2D measurement technology is used in sheet metal processing, but not exclusively; 3D measurement technology is used for bent, welded assemblies. Of course, other objects can also be measured in 3D.

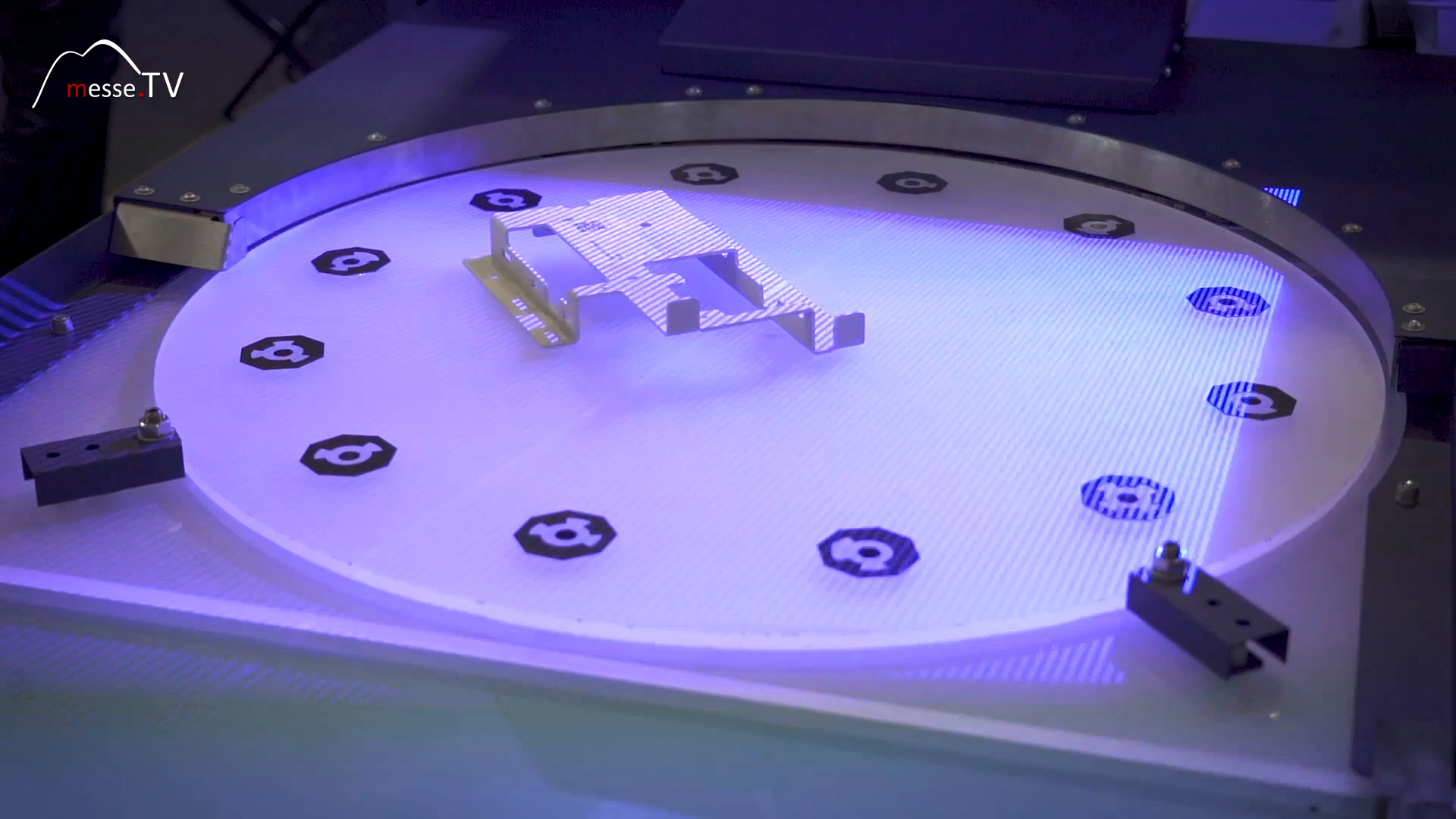

As a trade fair highlight, InspecVision is presenting a combination system that can measure both 2D and 3D parts. The 3D parts are captured by a rotating table and a scanner for measuring. After the measurement, the entire table can be pulled back to obtain a surface for measuring 2D. The 2D measurement works by means of LED surfaces illuminated from below and a camera installed at the top. When the light is switched on, the camera takes a picture of the components and software converts the contours of the components into measurement data.

InspecVision is constantly striving to optimize the software and to automate the measuring process smoothly so that the measuring process is as contactless as possible.