Schmalz: Vacuum Technology and Automation for Industry

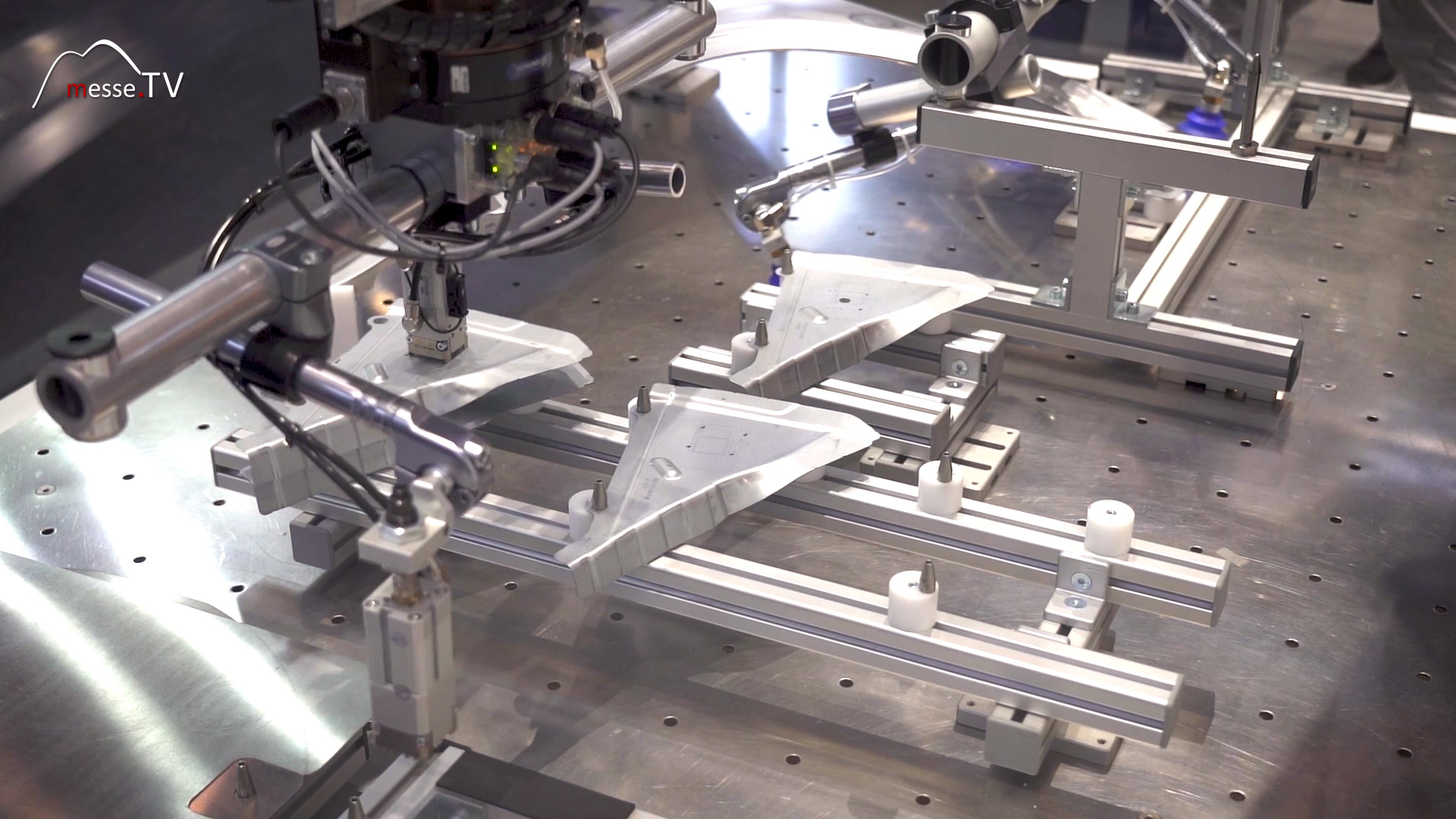

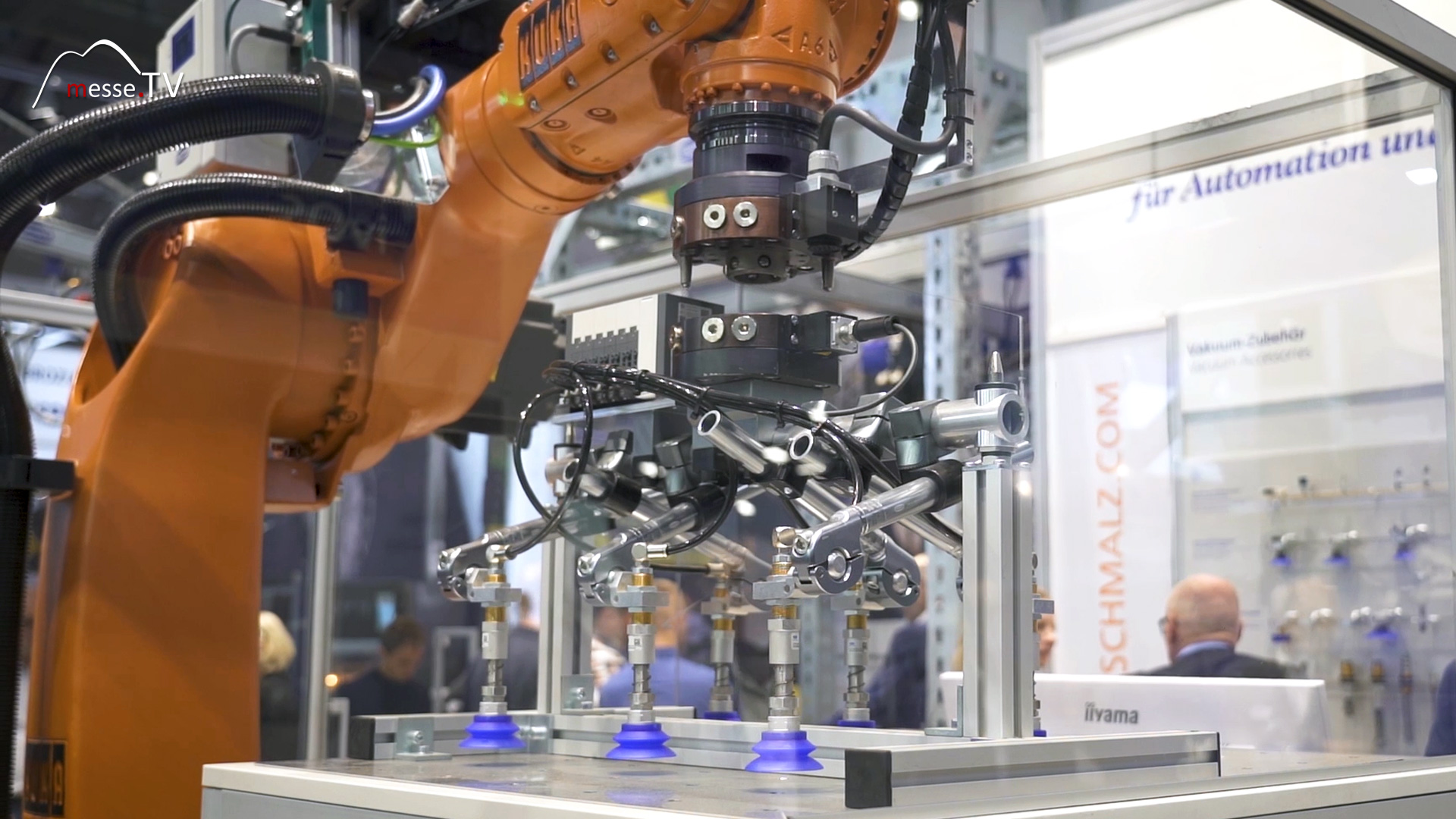

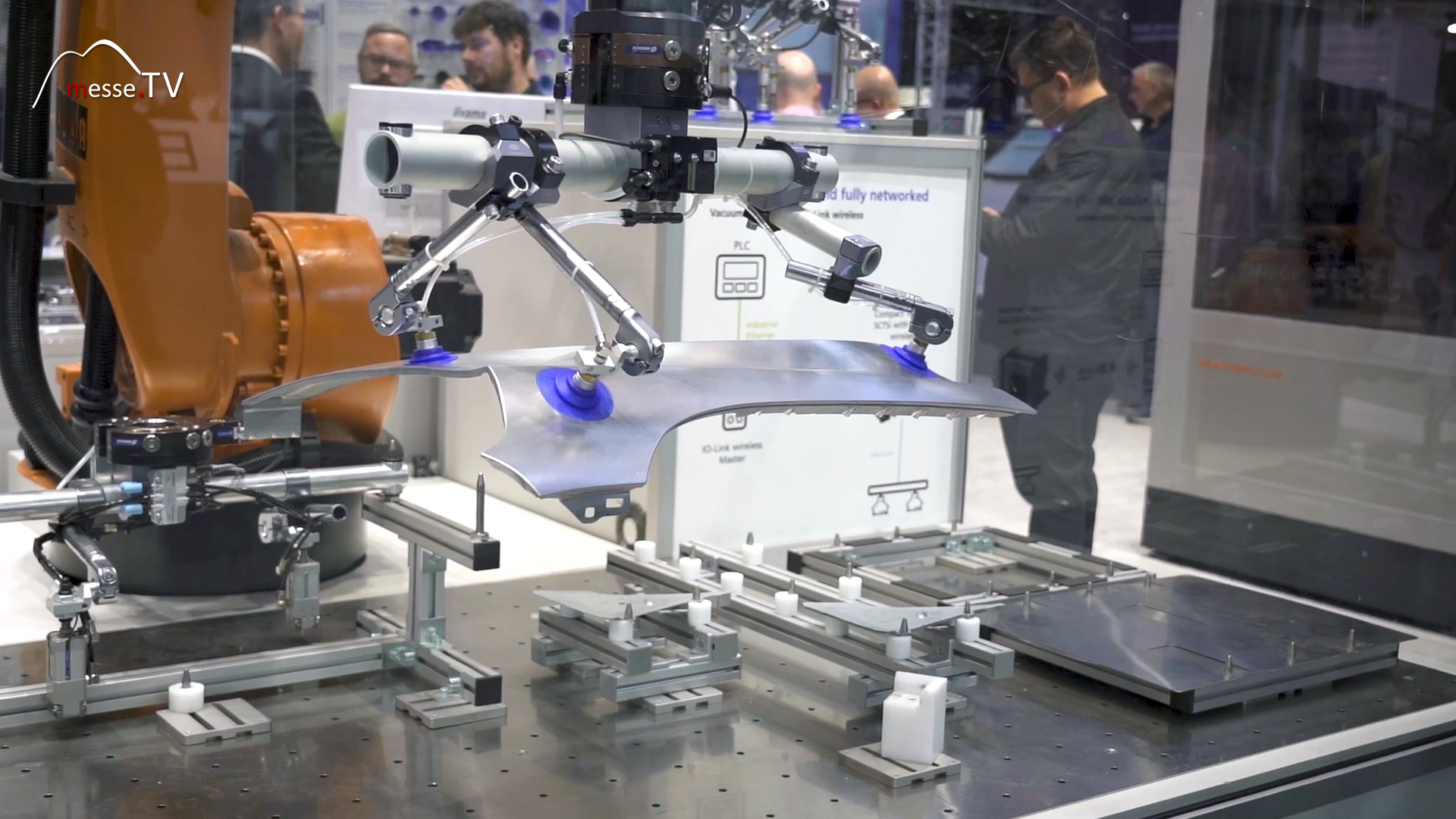

Schmalz produces vacuum components and systems for robots and handling devices to improve ergonomics when working with heavy workpieces. At Blechexpo 2023, the company will be demonstrating, among other things, optimal handling of a car body part for the automotive industry.

Handling sheet metal, furniture and plastic parts with robot systems

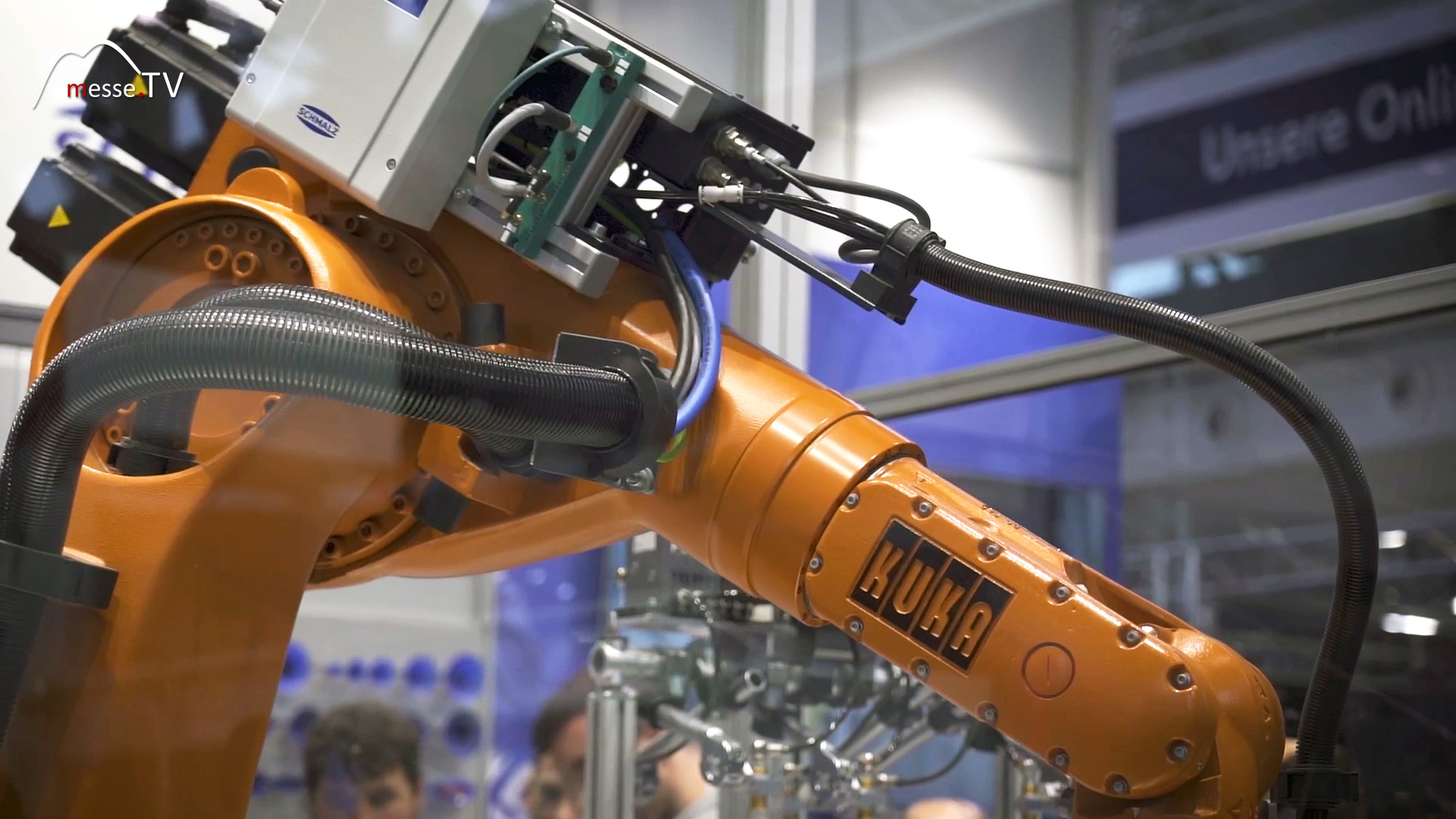

The international company Schmalz, with its 113-year tradition, is at home in the beautiful Black Forest. It employs a proud 1800 people in 30 countries with its own subsidiaries. Production takes place in the Black Forest, China, India, the USA, Australia and Poland. Schmalz is a dynamic, growing and highly innovative company. Schmalz products include vacuum components, systems for robots and for handling sheet metal, furniture and plastic parts. Furthermore, handling devices are produced that facilitate ergonomic work with heavy workpieces.

"Picking" gripping and handling sheet metal workpieces

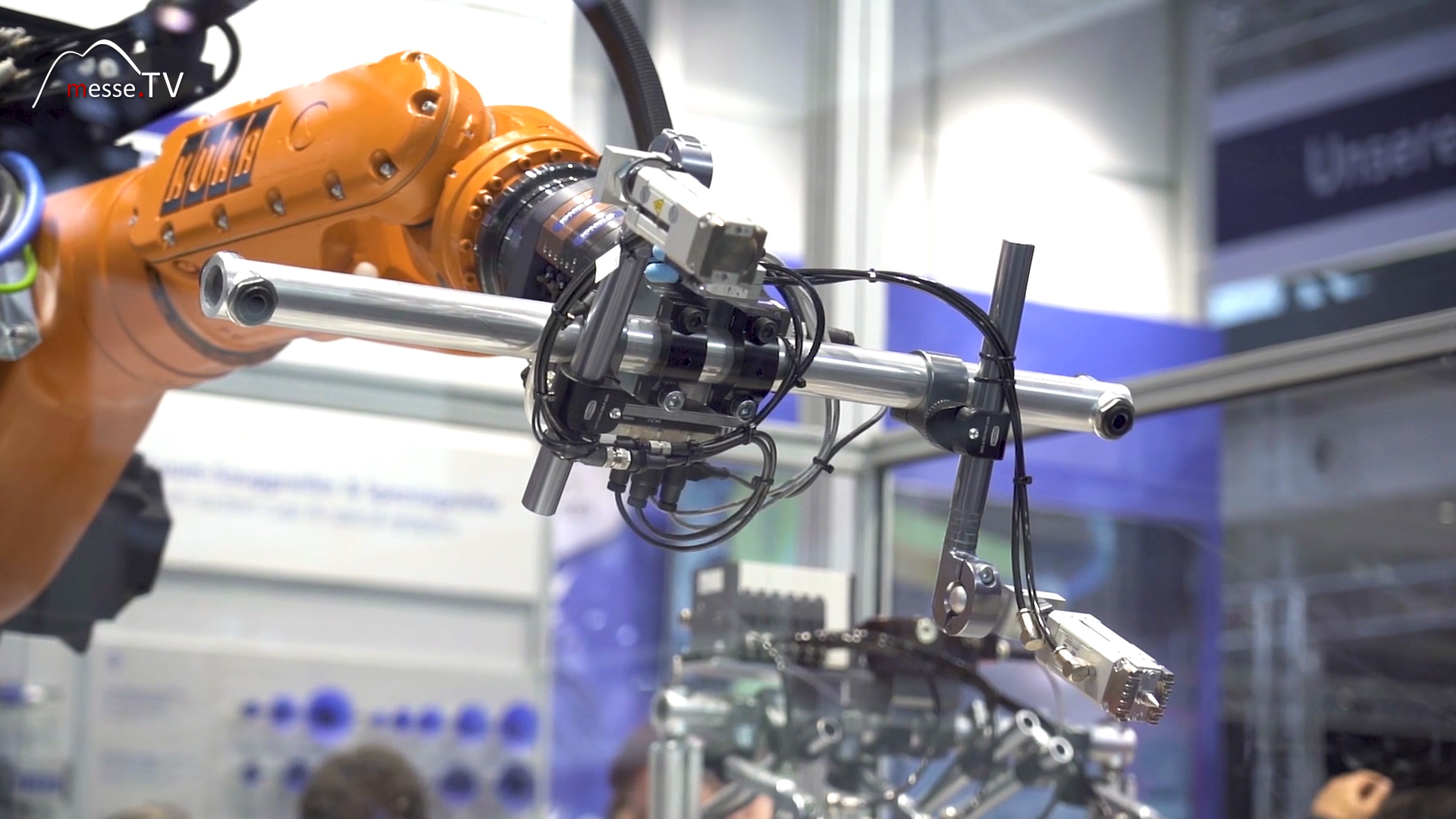

The fields of activity are, for example, in the automotive industry, for which equipment is created that is characterized by speed and energy efficiency. At Blechexpo 2023, Schmalz will be using the handling of a car body part to demonstrate the wireless communication of a vacuum generator, its control system and its sensor technology. Schmalz is the supplier of gripping devices for automation. The current hot topic is "picking", the gripping and handling of sheet metal workpieces. Together with camera and software, Schmalz offers so-called bundles for this area.

Schmalz invests heavily in research and development

The company works with 2 directions. That is, it goes to China and it is located in China. A new headquarters was opened in China in 2023. It is important for the company to know where the competition stands. The company invests heavily in research and development to bring new, innovative products to the market so that it is always one step ahead. The prevailing bureaucratic effort and costs in Germany cause difficulties. For this reason, the long-established company from the Black Forest is relocating production to countries such as China. The company would therefore like to see a rapid reduction in bureaucracy, better support in terms of energy costs and sustainable energy sources, better education and training, particularly with regard to MIT professions. The infrastructure, from transport links to internet connections, should also be improved so that Germany remains an attractive location.