From the coastal region of Slovenia, the company Sraml in Podnanos has been selling its wide range of machines for beverage technology worldwide for over 30 years. This includes machines for wine and juice production through to bottling plants.

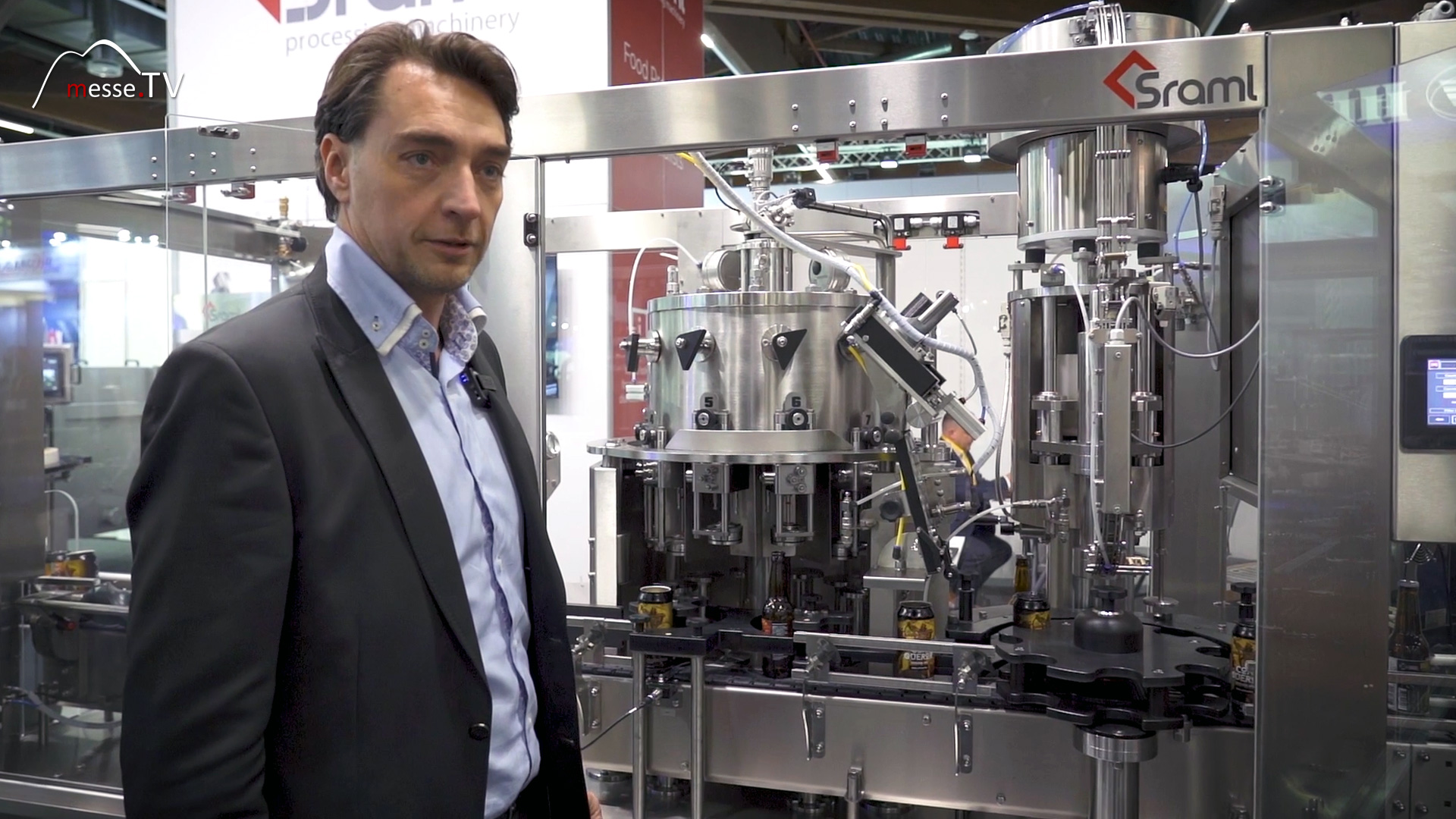

On site at BrauBeviale 2023, Mr. Denis C. Kebler will be demonstrating how a labeling machine works. Using a gripper system, several bottles can be picked up and lifted out of a pallet and then placed on a conveyor belt for further transport. This works in the same way with cans, which are placed on a table and automatically fed into the labeling machine. The heart of the system is where cans and bottles are first positioned and cleaned before they are moved on for filling.

Switching from one system to the other is quick and easy, with a changeover from can to bottle taking around 13 minutes. Filling is done with counter-pressure so that carbonated drinks can also be filled. They are then sealed. The capping mechanism can be rotated 180 degrees, with the device for can closures on one side and for cork closures on the other.

When the bottles or cans come out of the system, they are weighed. If they weigh too little, they are automatically sorted out. In the final step, the filled beverage containers are cleaned, dried and sorted into the waiting packaging.