DHL Embraces Robotics in Logistics

Robots in logistics? We talk to Markus Kückelhaus about robotics and automation at DHL at the transport logistic 2019 trade fair in Munich. Where is automation in the warehouse heading? Find out in our video.

Logistics: labor shortage, robotics and automation

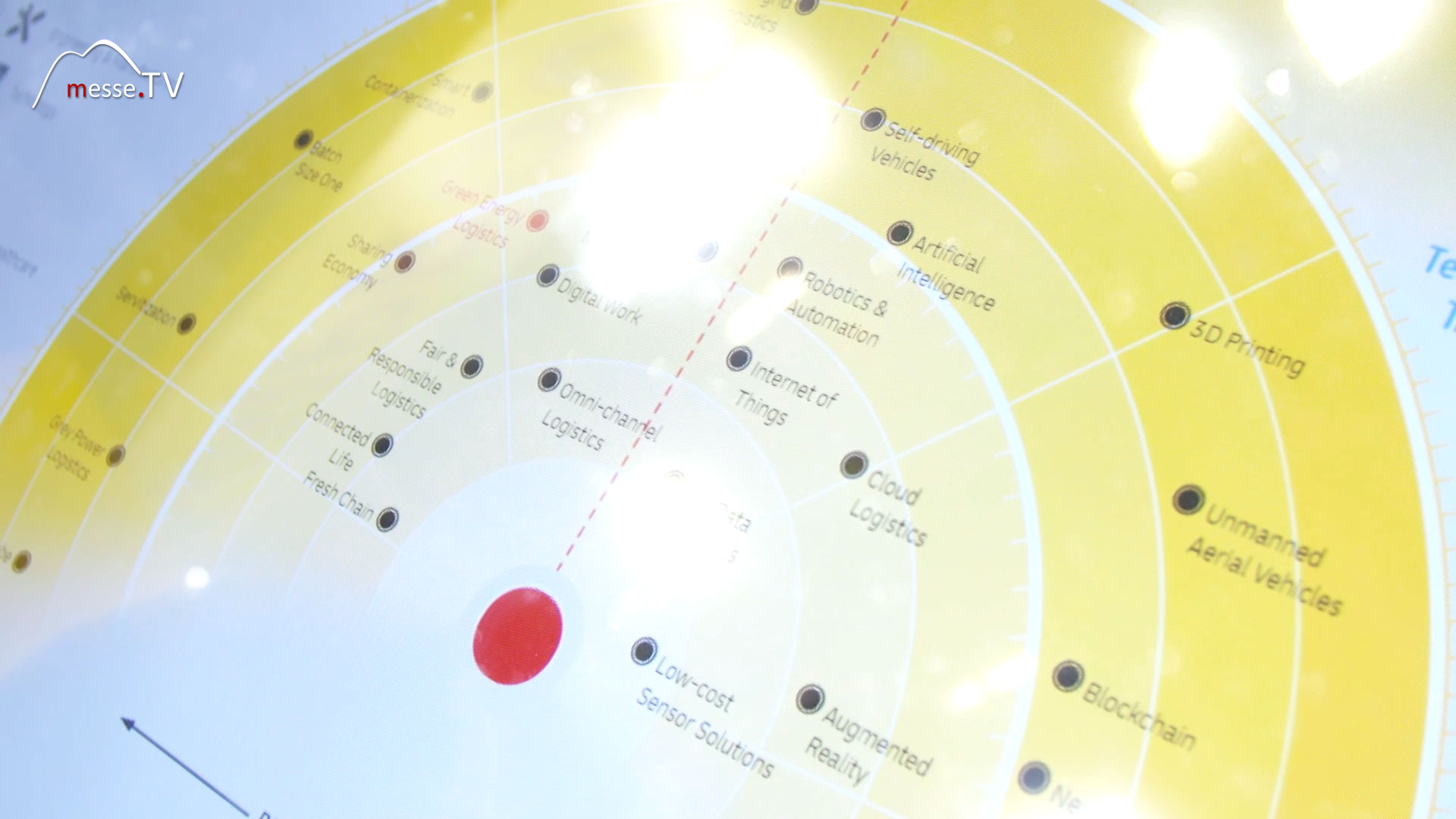

DHL needs a lot of people to cope with its daily tasks. As we know, our society is getting older and older and there is an increasing shortage of workers. How is the company meeting this challenge? ROBOTICS & AUTOMATION is a key topic that also appears on DHL's trend radar. Technology is of great importance. If you look at a typical warehouse around the world today, 80 percent of these warehouses are operated purely manually. Technology is needed here to meet the growing demand. In the past, there were primarily solutions with robots that had to be in a cage for safety reasons and were not allowed to work together with humans. Things are different today.

Robots as colleagues in logistics

A lot has happened in terms of technology and collaborative robots are increasingly being used. Humans are no longer working against a machine, but with a machine. What does it look like when the colleague is a robot? A classic example of an order picking process: the product is still best identified by the human eye, and the hand is still best for gripping the product. You no longer have to pull heavy things behind you yourself - a robot can help. Follow-me bots or similar solutions are already in use today and can help to relieve employees of very heavy work.